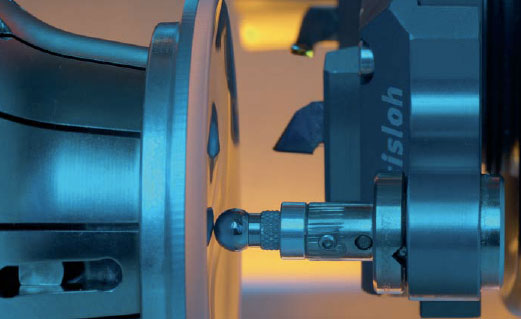

The photo above shows a Satisloh generator that calibrates (the ball surface touching the cutting surface) and the two diamond cutters that can cut to specific surface heights to create the curves and optics required "on-demand".

The result will be lens choices that meet the specific needs of each individual patient. Now, there is no more "one size fits all." The ability to completely customize the process will improve the patient's experience and increase their satisfaction with the final vision solution.

The foundation of a great single vision and progressive lens is found in the design, not in the way the lens is processed. However, an advanced design will fail the wearer if it is not fabricated correctly, while on the other hand, the most advanced lens making processes cannot make a lesser design better. Therefore, consider the importance of both the design and the process, the lab that the lens is purchased from. Together, your patient will be assured they have the best design, made to exacting specifications, for their vision needs.