Glass, Polycarbonate, CR-39, Trivex, 1.60... So many lenses, so little time! Do you ever find yourself overwhelmed by the amount of lens material options available on today's market? Or, do you have a "go-to" material that you tend to order without further thought? Does your office have guidelines on when you order a certain material over another (e.g., when do you choose hi-index over mid-index or aspheric over standard design?). If you answered "No" to the last question, it might be time to re-think your lens material selection strategy.

Where We Are (As An Industry)

Current research shows that one of the most common lens materials used today is CR-39, or also known as standard plastic. You know this one, it's been around forever. (Since 1947, in fact.) Let's take a minute to really let that sink in: 1947.

A close second was Polycarbonate. Slightly newer, polycarbonate has been used since the 70s. Yes, it has some technological advances over plastic—but this isn't really news, right? Polycarbonate certainly is a better choice over plastic when it comes to safety (impact resistance) and when it comes to UV protection. But, still, is it the best choice for your patients when you figure in polycarbonate's shortcomings in terms of ABBE value, specific gravity, and tensile strength?

So, think about the computer or handheld device upon which you're likely reading this article. Certainly it was manufactured much more recently than the 1970s. How about the car you drive? Surely you're not driving your great grandfather's Model T, right? Let's agree that we as an industry have produced some amazing things since 1947. Why are we still using antiquated technologies? Because they are "good enough?" Because it's what we've "always done?" When do we come to the point of demanding that "good enough" is no longer "good enough"—when do we put our patient first and insist they deserve better than "good enough"?

Better Options

Allow me to introduce you to a better option. Trivex as a material is hands down my favorite lens material.

Why? Let me count the ways...

- They have a fun history. Trivex was originally used in helicopter windshields for the military.

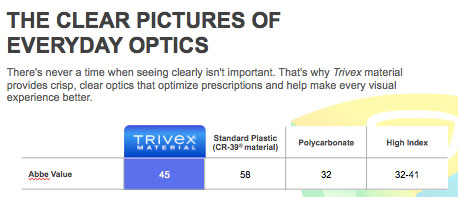

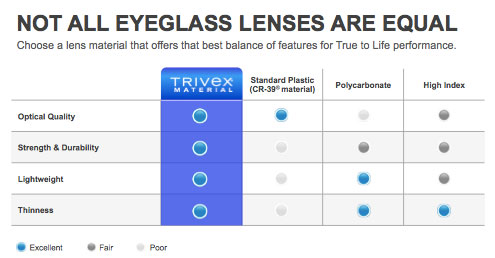

- They have an incredible ABBE value. 45! Especially when you consider polycarbonate has an ABBE value of 32. Translation: you see better through a Trivex lens due to a lower incidence of chromatic aberration.

- They are incredibly light in weight. Trivex has one of the lowest Specific Gravity ratings out there: 1.11. Consider this in comparison to polycarbonate's rating of 1.22. (Let's not forget that hi-index materials Specific Gravity ratings range from 1.30 to 1.47—so let's consider rephrasing the term "thinner, lighter lenses" when referring to hi-index lenses.) Translation: Trivex lenses are lighter in weight for your patient's comfort.

- They are tough. Trivex lenses are incredibly resistant to scratching.

- It is a new technology. Trivex lenses were introduced to the market in 2002. Of course we're in 2014 so these lenses are 12 years old, but compared to plastic and polycarbonate, these lenses are essentially newborns.

- They are inherently 100 percent UVA and UVB resistant, and we all know how important it is to protect our patient's eyes from the dangers of UV radiation.

- They have incredible tensile strength. Trivex lenses are not prone to stress fracturing when used in drill mounted or rimless grooved frames due to their high tensile strength.

- They are available for 85 percent of prescription ranges. If you think Trivex has limited availability, you'll want to check into this again.

- They are lenses that will set your practice apart. Trivex does not have widespread usage within our industry. (My research shows that only 6.6 percent of lenses ordered today from national laboratories are Trivex.) So if you are telling your patient that you can provide them something they won't be offered down the street, start talking to them about Trivex.

Want more information about Trivex? Check out their website at www.ppg.com

A Step Further

Want to up the ante in terms of visual acuity for your patients? Consider adding an aspheric design to your lens order. My research shows that only 1.7 percent of single vision lenses ordered from national laboratories today are ordered as aspheric. What a missed opportunity. Using an aspheric design flattens the lens and widens the visual corridor within your lens allowing for a more "edge to edge" type of vision within the lens rather than the commonly described "button hole" vision that occurs for patients of high minus or high plus powers. Not only will this improve the aesthetic of the lens, but your patient will notice the difference when they look through it. Again, this is not a commonly ordered design, so you would be offering your patient a product they likely haven't been exposed to. What a better way for your patient to leave thinking "Wow, no one has ever told me about this type of lens before!"

Decide to Be The Best

Our office has decided that if we are going to focus on using the newest technologies in terms of lens design (e.g., Free-form), then we must also use the most technologically advanced lens material available, so our standard lens material is Trivex for this very reason. Also, our office uses Aspheric lens design standard for anyone with over 1 diopter of cylinder, or for spherical designs over 2 diopters. Why? The patient deserves the best and they will notice the difference.

So, here is the challenge. Do you think your patient deserves the best and most technologically advanced products? Do you want to give your patient an experience and a product they aren't getting anywhere else? It may be time to rethink your standard lens usage.