By Linda Conlin

When we think about titanium frames, Charmant is the first name to come to mind. A leading multinational corporation for fashionable eyewear products, Charmant (the name means “charming”) began its journey of innovation from more humble roots. Let’s follow the journey from small manufacturer to a globally recognized producer and pioneer of quality titanium eyewear in cutting-edge designs.

In 1956, Kaoru Horikawa founded the company in Japan as a manufacturer of optical spare parts. Continuous innovation to improve manufacturing technologies led to the development of their own brands and products. In 1980, Charmant pioneered the introduction of titanium as a frame material and continued development and innovations in the use of special manufacturing techniques.

The first Pure Titanium collection was born in 1983, followed by the Titanium Perfection collection in 1987. The combination of comfort, fashion and function for both men’s and women’s designs make Titanium Perfection the number one brand in the Charmant Group. Continuing the quest for even lighter and stronger materials led to the introduction of Beta Titanium in 1990.

Memory Titanium, a highly elastic memory titanium alloy, comprised of 50 percent nickel and 50 percent titanium, debuted in 2007. This material not only retains its shape, it has 10 times the elastic behavior of steel. Quick on the heels of Memory Titanium came Z-Titanium in 2008. This new alloy consists of titanium and zirconium-titanium. The material is also used in the medical field because it is light, elastic, gentle and safe for the human body. Z-Titanium frames provide a softer and gentler wearing comfort than even that of Pure or Beta Titanium.

Charmant’s innovations continued in 2009 with the launch of Excellence Titan, exclusively invented for eyewear by Charmant in cooperation with Tohuku University. The result of eight years of research and development, this lightweight titanium alloy combines shape memory with flexibility for Charmant’s most comfortable frame material. Excellence Titan is the material utilized in the award-winning Line Art collection of frames. Excellence Titan is a titanium alloy with titanium’s strength and durability and hypoallergenic features, but with the added benefit of high flexibility and superb memory function. Line Art frames are more than just beautiful, they are lightweight and strong—and are scientifically engineered and ergonomically designed for the best fit, incorporating curved temples, adaptive nosepads and curved temple tips. While high-tech materials are the basis for high-performance frames, materials have to be coupled with design and manufacturing technology. One facet of that technology is the precision laser welding technique, able to join extremely fine parts directly, using no medium material that could cause possible breakage. It results in high-strength welding and gives a beautiful finish to fine eyewear. The typical welding method would cause problems such as the loss of the metal’s original characteristics, but precision laser welding, Charmant’s proprietary technique, offers limitless design options ensuring frames like those in the Line Art collection that are both aesthetically beautiful and comfortable with seamless joints.

Capitalizing on the success of the Excellence Titan material and ergonomic designs found in Line Art, Charmant introduced Perfect Comfort, a fusion of titanium and either Excellence Titan or Beta Titanium, creating a collection of comfortable and more accessible frames for men and women.

Titanium’s strength requires ramping up the processes used to manufacture frames made of other metals. Special soldering called brazing was required: Due to the porous nature of titanium, special high-temperature soldering machines in an oxygen-free environment at temperatures of 900 degrees or higher are required to securely bond solder points. Heavier pressing machines: Titanium’s strength requires heavier, more expensive presses to produce the frame detail, shape and design needed in the production of today’s fashion-forward styles. For surface treatments, Charmant uses specific techniques such as ion plating and hand painting (Neo 2) that not only result in fashionable colors, but reduce peeling for durability and function. At the end of that high-tech manufacturing process however, frames are inspected and finished the old-fashioned way—by hand.

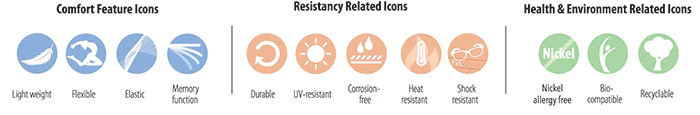

What do more than 60 years of research and development of materials and manufacturing technology mean for you and your patients? Frames that are lightweight, flexible, highly durable, corrosion free and nickel allergy free. Not only functional, the frames hold their adjustment, are comfortable, beautiful and exquisitely designed for both men and women, and are bio friendly. In short, Charmant eyewear embodies top quality, innovative design and cutting-edge style. Your patients value those qualities, resulting in high satisfaction and willingness to pay more for the best—a win-win.

Learn more about the unique titanium and titanium alloys Charmant produced through technological innovations as the original developers and producers of titanium eyewear, the challenges of the manufacture of titanium frames, the features and benefits of titanium frames, and more with the CE course “The Many Material Benefits of Titanium Frames” on page 125.