This is a reprint of a 2020 CE, part two of three with kind permission of the 2020 CE Study Center.

VERTEX DISTANCE

Ask just about any eyecare professional when knowing the fitting vertex distance of a pair of glasses is important, and they'll no doubt respond: "For powers over 6 diopters, you'll have to compensate the power for the difference between the exam vertex distance and the wearing vertex distance."

Although using the power threshold, as the marker for setting the threshold of importance for vertex distance was appropriate in traditional lenses, today's free-form optimized designs use vertex distance measurements as a far more important and essential element of lens optimization than power compensation alone. In digital lenses, informing the optimization engine of the fitted vertex distance enables the design algorithms to know precisely where the eye's central and peripheral gaze angles intersect the lens surface. This allows the manufacturer's software to calculate optimal corridor length, placement and inset.

Additionally, entering the actual lens tracing complements and leverages entering the fitted vertex distance, which further increases the optimization possible by reducing the lens areas the eye can't see or won't routinely access. In fact, neglecting to enter an exceptional vertex distance, defined as a fitted value less than 12mm or greater than 15mm, will significantly handicap the overall optimization process and reduce the promised performance gains possible in these fully customized lenses. ECPs are additionally advised to consult individual manufacturers to discover whether vertex-based power compensations are executed within the lens design's optimization algorithm. For many designs, traditional vertex distance power compensations are not routinely included in the lens calculations or verification values.

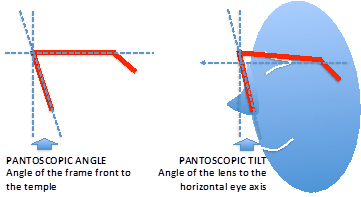

PANTOSCOPIC TILT

Not to be confused with Pantoscopic Angle, which is the angular measure between the frame front and the temple plane, Pantoscopic Tilt describes the vertical angle between a wearer's primary gaze and the intersection of the same with the plane of the lenses.

This is a yoked measure, meaning that both lenses are considered to be in the same plane, I.e. parallel for both eyes. Although the common range of values found is between 0 and 15 degrees, a wearer's natural posture can result in a negative value, defined as retroscopic tilt. A properly positioned, single vision corrected curve lens (compliant with Martin's rule of tilt) requires the lowering of the optical center 0.5mm for each degree of Pantoscopic tilt to ensure the lens surface is properly positioned to correct most off axis aberrations. The addition of the power corridor in progressive lenses compromises off axis clarity, making inclusion of as-worn Pantoscopic Tilt an additionally important priority.

In traditional progressive lenses, when the measured Pantoscopic Tilt value was found not close to the manufacturer's assumed fitting value, no further optimization was possible to compensate for degrading off axis effects. Additionally, both Pantoscopic tilt and vertex distance will often combine in a non-complimentary way, further degrading the utility and comfort of the progressive corridor.

Most eyecare professionals under appreciate the importance of Pantoscopic tilt. To illustrate, consider the degree of discomfort a wearer voices about the adjustment of their glasses when the plane of their eyewear is skewed (propellered) - meaning the lenses are no longer parallel to each other in front of the eye. Progressive wearers find even minor amounts of frame-front skew will cause significant visual distress and discomfort.

Should you specify the corridor length? Yes, if it will make a defined difference based on the questions asked of the patient and your observations of them.

For example, SEIKO Superior allows a choice of 11 corridor lengths in increments of 1mm starting with a 8mm length and minimum fitting height of 12mm (8mm, 12mm) all the way to 18mm length and 22mm minimum fitting height. That teaches you that for reading there is a 4mm reading depth. Want more reading? Use a shorter corridor length. Want to mimic the habitual glasses (the patient's current eyewear), consider that the reading is 4mm in depth and subtract that from the habitual glasses fitting height. The result is the targeted corridor length for the new glasses being ordered. The patient didn't have enough corridor width, lengthen the corridor by 2-3mms and corridors widen.

FRAME WRAP ANGLE

Frame wrap angle describes the horizontal angle of the lens plane in front of the eyes. The total frame wrap angle is measured with a common protractor, with one lens placed along the baseline of the protractor, and tracing a line tangent to the nasal and temporal limits of the opposite eyewire. The total wrap angle is then halved to obtain the angle for an individual eye. Unlike Pantoscopic tilt, frame wrap is a non-yoked measurement, meaning the tilt of a lens is opposite for each eye.

Traditional progressive lenses have always benefited from modest wrap angles, in the range of 5-7 degrees. Engineers prefer to use these values over a flatter angle because moderate amounts of wrap decrease the obliquity of the gaze angle in the periphery, which also decreases awareness of image degradation or distortion. Again, it is highly important to include the wrap angle when the measured frame value lies outside this range by two or more units in order to ensure optimal peripheral clarity.

KNOWN UNKNOWNS

Individual POW elements often interact with each other and impact vision in subtle, unpredictable ways. In discussing the interactive effects of vertex, Panto and wrap, it is assumed that the given prescription is accurate, leaving lens size, lens design, pantoscopic tilt, wrap angle and vertex distance as variables to consider when optimizing eyewear designed to deliver the ultimate in vision. For a designer tasked with creating a new lens design, the final lens size, the position of wear, the prescription change and the previous lens design are all considered to be known unknowns. Therefore, the design process begins with what is known: The Rx and how it was determined in the exam room.

Barry Santini, ABOM, graduated from New York Technical College in 1975 with an AAS in Ophthalmic Dispensing. He is a New York State licensed optician with contact lens certification, is ABO certified and was awarded an ABO Master in 1994. As sales manager for Tele Vue Optics from 1987 to 2003, Santini developed his knowledge of precision optics and has been an owner of Long Island Opticians in Seaford N.Y. from 1996 to present. In addition, Santini is an amatuer astronomer and lecturer and plays bass trombone in the Brooklyn Symphony.