Abrasion and Scratch Resistance: Although there are several test methods for testing abrasion resistance, there is not one universally agreed upon standard. Abrasion resistance is actually a combination of different factors—adhesion, hardness, flexibility and impact resistance. Each test method measures a different combination of these factors. Since each of these test methods measures a different combination of features, they do not always correlate with each other. It is possible to have excellent steel wool scratch resistance and a low Bayer Ratio and vice versa. Some of the most durable coatings are designed to give the best combination of abrasion resistance as measured by several of these test methods.

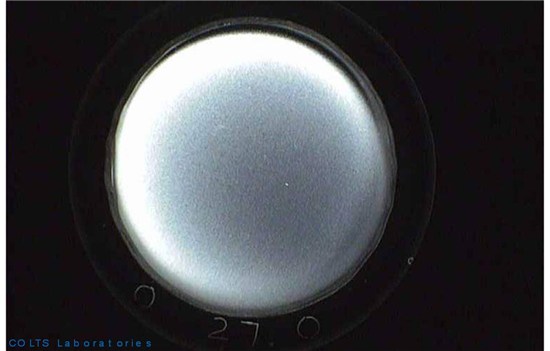

Bayer Abrasion: The Bayer test is one of the most often cited test methods for abrasion resistance. This test subjects both a coated lens and an uncoated CR-39 standard to abrasion from oscillating "sand." The sand is actually alumina zirconia. After a set number of cycles, the haze gain is measured on both lenses. The ratio of haze gain of the uncoated lens to the coated lens is the Bayer Ratio. A Bayer Ratio of "1" means that the coating has equivalent abrasion resistance to uncoated CR-39. A Bayer Ratio of "5" means that the uncoated CR-39 standard had five times the haze gain as the coated lens. A common standard Bayer Ratio equal to "4" or greater is considered by the industry to be a premium coating.

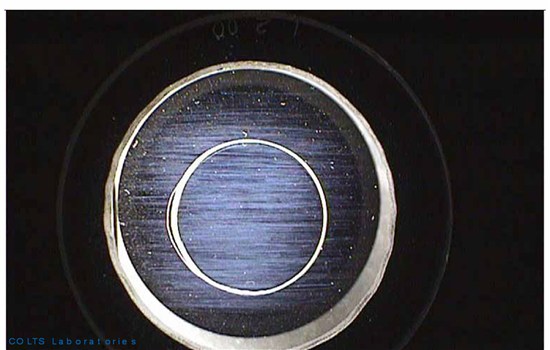

Images: Colts Laboratories

Haze

Steel Wool Abrasion: Steel wool is a popular test because a version of this test can be performed without any special equipment. There are different ways to conduct a steel wool test. The simplest is to rub the lens by hand with a small piece of steel wool. This method gives a qualitative rating from poor to excellent. There is also equipment available that rubs the lens with steel wool under a specified weight for a specified number of cycles. This type of steel wool test gives a quantitative measurement. The steel wool is of known fiber size and quality.

Steel Wool Abrasion

Other Abrasion Test Methods

There are several other methods to measure abrasion resistance. They are the Eraser test, Tumble test, Taber test and Nanoscratch test. The two most common methods, however, are the Bayer and the Steel Wool test.

Adhesion: It is critical that any coating exhibits excellent adhesion to the substrate. Poor adhesion results in delamination or peeling of the coating. Adhesion is measured by a Cross Hatch test. A cross hatch pattern is cut into the surface of the lens by using a sharp blade to cut a set of parallel lines through the coating and a second set of parallel lines at 90 degrees to the first set. A piece of tape of a specific grade is then pressed against these lines. The tape is quickly lifted off. This is typically repeated three times. The cross hatch is then examined for delamination. To achieve a rating of 100 percent adhesion, there cannot be any areas where the coating is lifted or removed. This test is commonly performed after the coating has been cured. This reading would be the initial adhesion. This test can also be performed after tinting or exposure to boiling water. This would then be called the post-tint adhesion and the boiling water adhesion test. In each of these cases the lenses would also be evaluated for small cracks or crazing.

Coating Thickness: Coating thickness is typically measured by a UV/VIS spectrophotometer or smaller portable device. Coating thickness is important, as too thin a coating will result in decreased abrasion resistance and too thick a coating may result in delamination or poor adhesion.

Tintability: Tintability is measured by subjecting the coated lens to a tint bath. The tint density is then measured as a function of time. Both tintable and non-tintable coatings are tested for tintability. A nontintable coating on the front side of a lens must be tested to ensure that the coating does not delaminate or craze upon exposure to tint bath. Manufacturers perform a second adhesion test after tinting.

In-Process Testing: There are many tests that are conducted during the coating process. These can include viscosity, percent solids, temperature and humidity. These values give a good indication of the age of the coating and the processing conditions. As liquid coatings age, the viscosity and other features may change. This will result in changes to adhesion, abrasion resistance, tintability and coating thickness. Processing variables such as temperature and humidity also impact these features. It is important to have a clean and controlled process to achieve a coating with optimized optical properties and mechanical performance.

WHO TESTS?

Not all tests can be performed at all locations due to the need for special equipment. Some tests, such as in-process testing of the coating liquid and environment are performed at the location where the coating is being applied. Tests that require little or no special equipment can be performed at a lab, retailer or office location. These would include handrub steel wool, cross hatch adhesion and tintability. It is important to note, however, that most of the tests are destructive. This means that once the test is performed, the lens is often not usable. Tests that require special equipment (Bayer, quantitative steel wool, coating thickness by spectrophotometer, etc.) can only be performed at laboratories or manufacturing locations with the appropriate equipment and trained personnel. If one desires to run one of these tests and does not have the necessary equipment or personnel, there are test labs that can perform these tests for a fee. Often, it is not important to be able to run these tests onsite. What is more important is to have an understanding of what these tests are and an understanding of the results being looked for to meet performance goals.