Sponsored by IOT

By Deborah Kotob

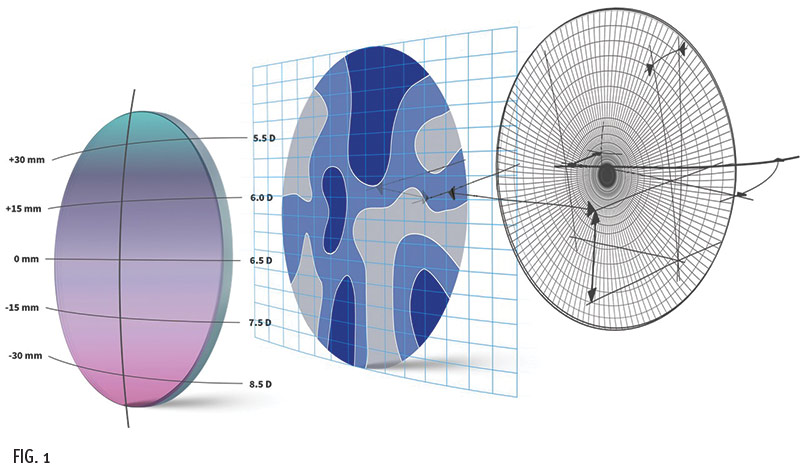

With the plethora of progressive lens designs on the market, how do we determine the best design for the individual patient? One way is to stay informed about breakthroughs, quantifiable improvements in the performance parameters the patient needs for their daily wear or task-specific PALs. This article will discuss the breakthrough CamberTM PAL design with a clear, large, easy-to-find reading area that facilitates easy adaptation. The design achieves best-form optics by starting with an increasing variable base curve front surface (Fig. 1). This variable base curve front is combined with the complex free-form calculations that map the optimal back surface merging the two surface curvatures to produce optimal distortion-free optics for distance vision and throughout the progressive corridor.

Free-form design software and surfacing equipment have been the most significant breakthrough in PAL designs over the last 15 years. But even free-form lenses are shown to be measurably better when we start with an increasing variable base curve front instead of the typical backside application of the Rx, PAL design and personalization parameters. According to Wollaston and Ostwalt, every power has an ideal base curve to minimize oblique aberrations; therefore, since the power of a progressive lens changes from distance to near, the front base curve should change too.

Typically free-form software computes the best surface topography for the back surface of the lens based on the Rx, PAL progression and personalized frame fit parameters. A data points file is generated that guides the CNC machine as it applies the surface to the back of a spherical single-vision lens blank. The correct front curves are lacking because a spherical single base curve blank has only a single base curve, requiring backside correction of the power errors at near caused by an incorrect base curve. Oblique aberrations encroaching on the near area result in unwanted cylinder and an effectively higher add than required by the wearers at that point. You might ask if the wearer perceives the difference between backside compensation of errors at near compared to the variable base curve Camber blank design. The following wearer trial answers this question.

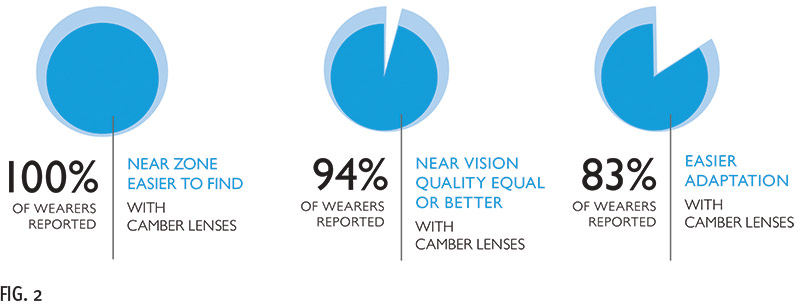

In a double-blind study, test wearers compared the same progressive design, one engineered with Camber Technology and the other without it. Proven results: In the wearer trial, 100 percent of wearers reported near vision easier to find with Camber lenses. Wearers perceived improved peripheral vision and wider visual fields (Fig. 2). Further support comes from a clinical assessment by IOT which conclusively showed a 9 percent increase in undistorted near vision area with an increasing variable front base curve blank over a spherical base curve blank.

The Camber variable base curve lens blank combined with IOT Digital Ray-Path 2 Technology and Steady Plus Methodology works synergistically to expand the Rx range, minimize the swim effect, provide better cosmetics (flatter), improve binocular vision in the intermediate and near zones, and increase distance fields of view. To produce Camber prescription lenses, cutting files are optimized using IOT Digital Ray-Path 2 Technology and Steady Plus Methodology to trace, analyze and compute the best surface profile across the lens to accommodate the prescription and frame/fit parameters and minimize lateral and oblique aberrations. This technology leads to a personalized lens enabled through a rigorous lab enablement process so that the Camber lens wearer experience is outstanding, surpassing all prior experiences.

IOT Digital Ray-Path 2 Technology is a new method of calculating the optimal lens surface to produce accurate power for all gaze directions and object distance ranges in the accommodative space; the result is customized lenses with superior compensation of oblique errors for broader, clearer fields of view.

IOT Steady Plus Methodology is unique to the Camber lens. It improves upon past efforts that only reduced lateral distortions by minimizing the cylindrical component of the sphero-cylindrical error. With Steady Plus Methodology, both the mean power (spherical) and the cylinder power errors are minimized. The technology employs new mathematical methods to compute the best lens topography to achieve the least distortion and swim effect without reducing progressive lens optical performance. As a bonus, the wearer experiences binocular symmetry (equivalency) in the near zones for greater reading comfort.