Sponsored by IOT

By Deborah Kotob

Historically, producing optically viable high-wrap eyewear was limited and required specialty labs (especially for progressive lenses). Conventional manufacturing methods were only capable of generating a sphere or torus on the back surface of the lens. Therefore, only a narrow range of prescriptions could be produced in high-wrap frames. Labs that dealt in high-wrap eyewear used formulas to calculate and compensate for the power error and oblique astigmatism caused by the angle formed between the visual axis and the lens optical axis in the primary gaze position. They also added equal and opposite prism to cancel the induced prism. Later came aspheric designs that improved peripheral optics when they fit correctly but still had room for improvement. Thankfully, we now have free-form lens design and production that overcomes the constraints of conventional technology, allowing for a wide range of prescriptions and precise point-by-point optimization of the lens surface: compensating power errors, minimizing the oblique aberrations and prismatic effect inherent in high wrap eyewear.

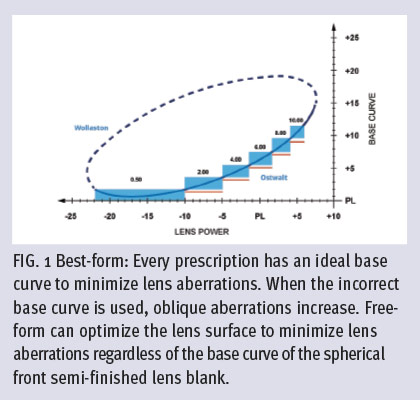

In conventional lens design, every prescription would ideally be ground off the back of a lens blank with the best-form base curve (Tscherning) to minimize oblique aberrations (Fig.1). But in high-wrap frames, the base curve is +8.00D typically and not best-form. However, a free-form compensated lens is calculated considering the base curve, allowing manufacturers to select different base curves and still have a good quality of vision within certain limits. Additionally, prism is induced in high-wrap eyewear. “The prismatic effect depends on the gaze direction, as well as the decentration of the lens. A tilt due to pantoscopic or wrap angles induces decentration of the lens relative to the visual axis, and the prismatic effect is a consequence.

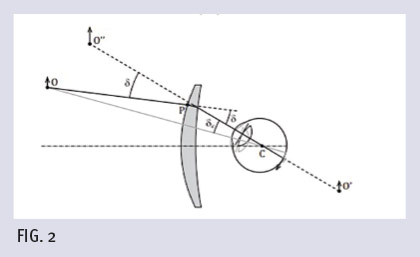

However, the amount of prismatic effect will always depend on the power of the lens. Fig. 2 shows when the eye is rotated and viewing off-axis. In this case, there is a prism effect P, so the image of O’ moves to O”. Now imagine that the lens power is different, and therefore the thickness; this prismatic effect will change because it depends not only on the obliquity of the lens but also on the lens power. Prentice’s rule is the way to describe mathematically how the ray is deflected in a prism. The prism can be caused in different ways, one of which is the tilt.” (Pablo Concepcion, clinical optometrist, IOT)

So prism and lens aberrations are two optical challenges inherent in high-wrap eyewear that are dramatically reduced with advanced free-form design and surfacing technology. Free-form lens design and manufacturing technologies introduced new calculation methods that compute and minimize the unwanted sphere and cylinder power errors (oblique aberrations) that otherwise degrade visual acuity for the lens wearer and compensate for the power errors caused by obliquity.

The following excerpt uses a specific example to illustrate the unwanted effects of high-wrap eyewear and how free-form optimizes the entire lens surface point by point to minimize aberrations. “The lens has a refractive power of +6.50D, produced with a base curve of +8.00D and fitted in a frame with a wrap angle of 15 degrees, pantoscopic angle of 8 degrees, and back vertex distance of 14 mm. As expected, the lensometer power of the conventional lens is constant (both sphere and cylinder) all over the surface of the lens. However, the cylinder of the user’s perceived power grows above 2D at the nasal and temporal sides due to the strong oblique aberrations produced by this combination of power, base curve and tilts. The area without significant aberration is reduced to two points in the central area of the lens. On the other hand, for a free-form SV lens compensated according to the individual personalization data, the spherical and cylinder power change point by point all over the surface of the lens.” (Eva C, Jose A, Jose M C, Daniel C. “Free-Form Lenses: Why My Patient is Not Wearing My Prescription?” JOJ Ophthal. 2017; 2(1):003 555577. DOI: 10.19080/JOJO.2017.02.555576)

IOT has further enhanced lens optics by optimizing the accommodative space object with their new IOT Digital Ray-Path 2, which minimizes oblique aberrations more effectively. For each fixation point, the design incorporates small naturally occurring accommodative power adjustments made by the wearers’ accommodative system into the traditional calculations for reducing oblique aberrations. With the IOT Endless Sport Progressive designs, progressive lens wearers can experience a clear 180 degree field of view in high-wrap eyewear thanks to the optimized optics of IOT Endless Sport Progressive designs.