Sponsored by IOT

By Tina Lahti, ABOC

This article is the third in a series of articles from Tina Lahti, VP of sales and marketing for IOT, and a longtime optician and industry educator. Tina shares informative tidbits from her course “What Your Lab Wishes You Knew.”

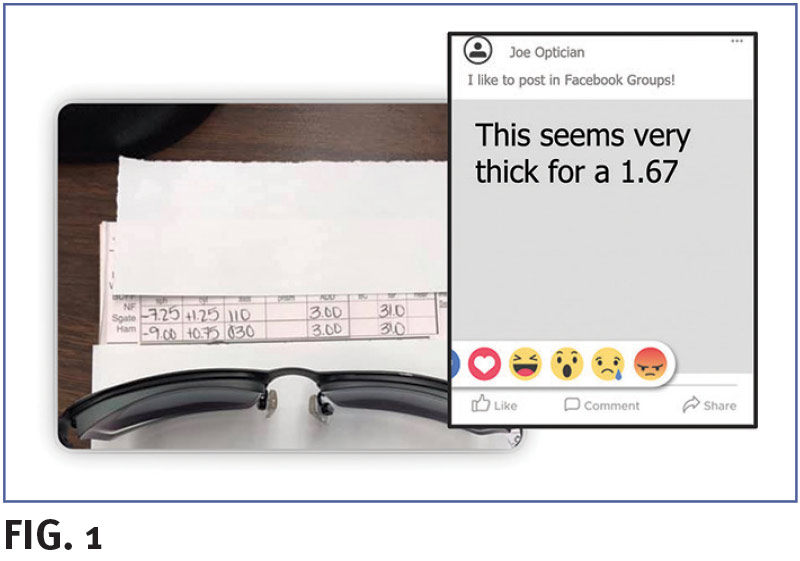

This article reviews the effects of lens decentration on lens thickness. This photo (Fig. 1) was posted along with the comment, “This seems very thick for a high index 1.67 lens.” The comment stream went quite long, and most comments pointed to the lab or the center thickness of the lens as the culprit. Eventually one optician said this: “100 percent poor frame choice is to blame… no matter what lab or material… the end.” The optician who wrote this comment is my new personal hero.

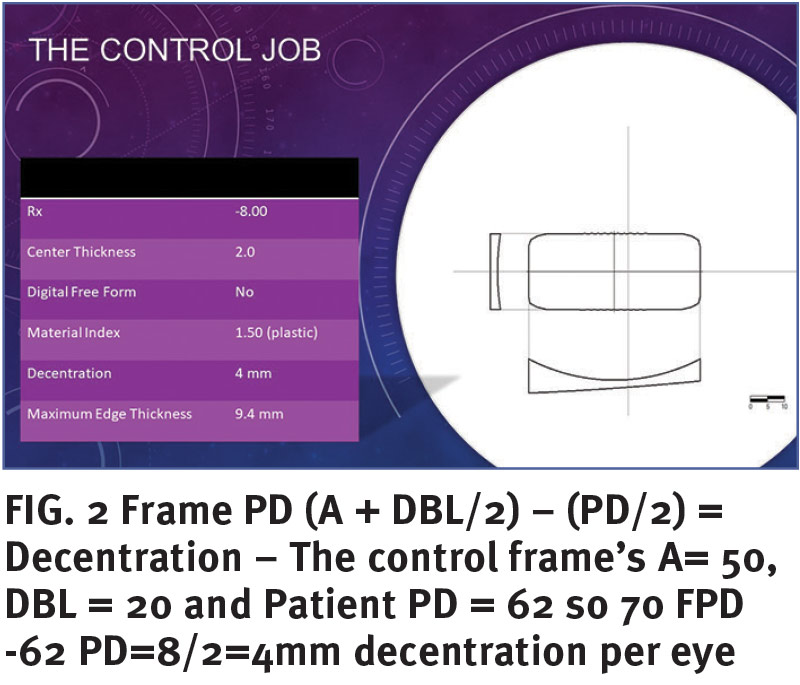

To examine the contribution of decentration relative to lens edge thickness, we started with a control job. How much does decentration matter? A lot. If the 4 mm of decentration is eliminated from the control job (Fig. 2), but all other lens properties stay the same, the edge thickness is reduced from 9.4 to 6.3 = 3.1 mm or by 33 percent. IOT compared the effect of each lens property on lens edge thickness individually. No other factor had as large an impact on lens edge thickness as reducing or eliminating decentration. For example, changing the control job’s index of refraction from 1.50 to 1.60 reduced edge thickness in this -8.00 D lens by 1.3 mm or 14 percent, so the material index had the second largest impact on edge thickness. Changing from conventional to freeform digital processing reduced lens edge thickness by a very small 0.2 mm or 2 percent, primarily by changing the center thickness. Changing the center thickness of the 1.50 index from the required 2.0 center thickness to 1.5 center thickness reduced the edge thickness by 0.4 mm or 4 percent. The relationship between center thickness and edge thickness is pretty much one to one. In other words, if you minimize center thickness by half a millimeter, you reduce edge thickness by half a millimeter. That’s it! The center thickness of a lens isn’t arbitrary. Minimum thickness is determined by impact resistance requirements in a given material and to minimize birefringence during surfacing for highly birefringent materials like polycarbonate or high index materials.

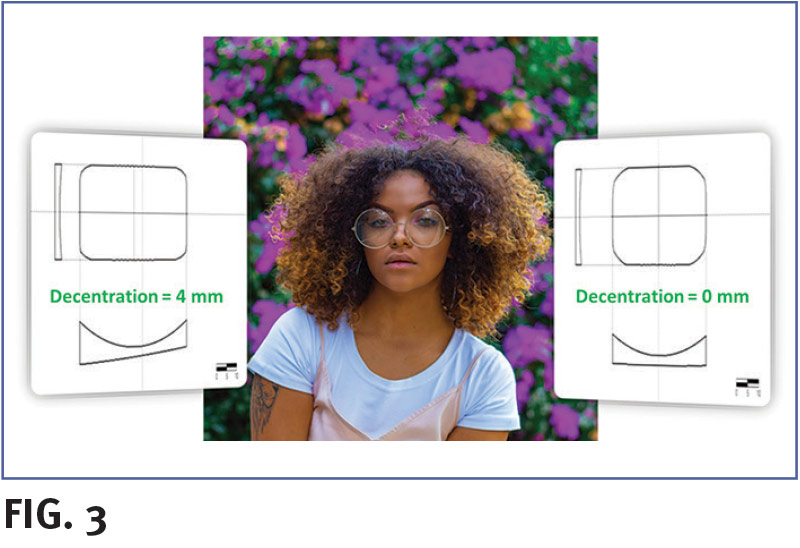

So you can see how important it is to control the narrative when it comes to frame selection. Patients with low prescription power aren’t a problem. Someone with a -0.50 Rx can go for it and have fun! But the story changes as the prescription power increases. If you fit a -8.00 in this 70 FPD frame with 4 mm decentration, well, that’s just optical malpractice. Look for a frame that is a better fit while giving the patient the overall style and look they want. Understand that they can’t envision the completed pair of glasses by trying on a pair with plano demo lenses. You can help them envision the end product. Keep a high minus surfaced lens available to show the patient and allow them to feel it. Encourage them to feel how thin the center thickness is compared to the edge. Explain that the larger the frame, the thicker the edge and the better their eyes are centered in the lens, the thinner the edge thickness. You can also use lens calipers with a high minus lens to show the difference in thickness from the center to the edge.

Explain if they choose the larger frame, they will end up with 9.4 mm of edge thickness. But if they choose the smaller well centered frame, they’ll reduce the edge thickness to 6.3 mm. Draw a 9.4 mm line next to a 6.3 mm for a quick visual comparison. Make sure they understand the larger frame means thicker and heavier lenses. On another note, the weight of a large poorly centered frame will cause it to slide down the nose as seen in this picture (Fig. 3). Ultimately, it’s the patient’s choice but our job is to make sure they make an informed decision. Hopefully it’s clear the best combination of lens properties produces the least edge thickness, but decentration plays the biggest role, followed by material index.