Sponsored by IOT

By Tina Lahti, ABOC

This article is the second in a series from Tina Lahti, VP of marketing and sales for IOT, and a longtime optician and industry educator. In this series of articles, Tina shares informative tidbits from her course “What Your Lab Wishes You Knew.” In Part 21, Tina will continue with how frame information contributes to the finished lens and why it is important to provide the lab with this key information.

Frame information plays an important role in cut out. I know we’ve all heard this phrase, but do we really know what it means? Cut out is exactly what it sounds like. Imagine you’ve rolled out some cookie dough, and you must determine how many cookies you can cut from that flat sheet of dough. Well, it depends on the size and shape of the cookie cutter. Using a smaller shape cookie cutter will result in more cookies.

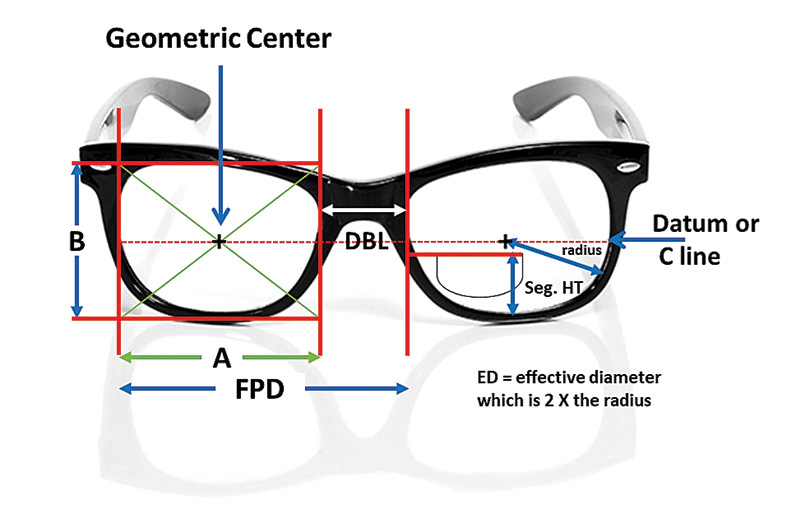

For ophthalmic lenses, using minimum blank size (MBS) arrived at by (GCD – PD) + ED results in the smallest lens blank to meet the prescription requirements. Lenses, unlike cookies have power, and the power is clearest at the lens optical center requiring they be centered properly in front of the patient’s visual axis (pupil); therefore, decentration is a key component to determine the lens minimum blank size and cut out. Minimum blank size (MBS) is determined by the amount of decentration. (Decentration is how much the patients’ pupils are displaced from the frame’s geometric center, horizontally.) Adding a couple millimeters to the MBS is recommended to allow for imperfections at the edges of an uncut lens. Lens blanks are available from the manufacturers in set diameters between 60 mm to 80 mm and in 5 to 6 mm steps.

You may ask, why is there a MINIMUM blank size, why not use the biggest lens blank available? The answer is thickness. The larger the diameter of a lens blank, the more center thickness in a plus lens and the thinner the plus lens edge which can lead to breakage, flaws and poor lens retention in the frame. Conversely, the more decentration in a minus power lens, the greater the temporal edge thickness, since minus lenses are thinnest at the center.

- The higher the focal power of a lens, the greater the lens maximum thickness (plus power center thickness or minus power edge thickness).

- The higher the refractive index of a lens, the more the lens maximum thickness decreases.

- The greater the lens blank diameter, the greater the lens maximum thickness.

For lenses, minimum blank size for cut out is a key consideration but lens minimum center thickness is another cut out, comfort and lens retention issue. We see examples of this when a lab is surfacing a plus power lens. In a plus power lens, the size and the shape of the lens directly impacts the center and edge thickness. Why? Because there is an ANSI standard minimum lens thickness requirement, and plus lenses are thinnest at the longest radius or furthest point from the patient’s pupil to the eyewire edge. In some frame shapes, such as rectangles with sharp corners, the lab will err on the side of having enough thickness. This makes the lens thicker and heavier than necessary.

Surfaced spherical plus lenses are almost always thinner than a stock lens. This is especially true for small children with a plus power Rx. A stock polycarbonate plus powered lens generally has a 1.5 to 2 mm edge thickness and a 65 mm diameter. If you are fitting a child in a 46/16 frame, and they have a 60 mm PD (30 mm OU), they have only 1 mm of decentration per eye. This is as close to an ideal fit as you are going to get, typically. A surfaced lens would be, about 2 mm thick at the furthest edge but a stock lens would be 2 mm thick 8 mm beyond that, increasing the thickness of the lens and weight of the lenses dramatically. One of the kindest things you can do for little hyperopes is order surfaced lenses and supply your laboratory with complete frame information.

Join us in next month’s issue of 20/20 Pro to Pro for more on What Your Lab Wishes You Knew.