Many leaders in the vision industry expect Free-form technology to be the next revolution in vision correction. How can we wrap our minds around this complicated technology and, even more important, how can we explain it to our patients?

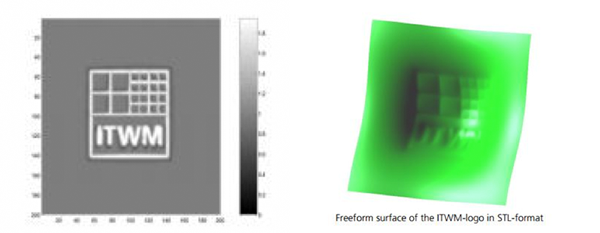

There is genius in simplicity. So, let’s keep it simple. Free-form is a manufacturing process that allows the production of complex surfaces and designs with extreme precision.

To understand complex processes examining the history may give us some clarity.

The History of Freeform Lenses

| Late 1970s | Computer numerically controlled cutting (CNC) was being used in the aerospace and automobile industry |

| 1985 | OptoTech’s founder Roland Mandler started using CNC in optics |

| 1986/87 | Gunter Schneider of Schneider GmbH & Co. KG, Germany started to use computer-controlled processes in precision optics |

| 1987 | CNC (Computer Numeric Controlled) technology was used in the production of devices needing high precision lenses |

| 1991 | Marc Savoie started testing the feasibility of Free-form |

| 1993 | Carl Zeiss suggested that Schneider Optical Machines should consider developing equipment that could cut ophthalmic lenses with complex surface geometry to prescription |

| 2000 | Zeiss and Rodenstock launch their first Free-form PALs |

| 2000 – 2010 | All lens manufacturing companies launch their Free-form PALs |

| 2009 | SV Freeform is launched |

| 2010 – Present | Private label Free-form lenses are on the rise |

So... Free-form technology has been around for several decades. It was used in the aerospace and automobile industry. The precision optics industry started using CNC – Computer Numeric Controlled - technology in the late 1980s to manufacture lenses for devices needing high precision. Hoya, Essilor, Rodenstock and Zeiss started using CNC cutting and polishing systems to manufacture their glass molds in the early 1990s. And then finally in 2000 Zeiss and Rodenstock came out with the first progressive lenses using direct-to-lens surfacing. This was made possible by highly advanced generators. As the technology advanced, so has the equipment. The interest among the laboratories is extremely high, limited only by the cost of the investment, a minimum of $400,000 to well over $1 Million.

There is no question that Free-form technology is a gift to all opticians that specialize in designing their patient’s eyewear. If you love to coach your patient through the process of finding the perfect eyeglasses, freeform technology is for you. If you want to brand yourself as a vision specialist, setting yourself apart from online and discount providers of eyeglasses, freeform technology is your vehicle to success.

And here is what you need to know . . .

Free-form Progressive lenses are:

Individually Measured, Computed and Manufactured Progressive Addition Lenses Using Computer Programs To Run Three-Axis Generators and Polishers to Provide the Wearer With an Optimized Lens Correction For A Visual Defect.

The process consists of three separate but totally dependent parts:

- A progressive lens design

- A software program

- Very specific processing equipment

The Designs

| Optimized

Free-form Design can be used to overcome optical aberrations and mechanical limitations of Traditional surfacing. |

Framitized

The PAL designs are modified to specific fitting, frame or adjustment characteristics. |

Personalized

The PAL designs are created specifically to the prescription and individual viewing habits of the user. |

The Software

The key to the new “Free-form” lenses is the software that calculates the curves for the individual designs and drives the machinery to manufacture the lenses.

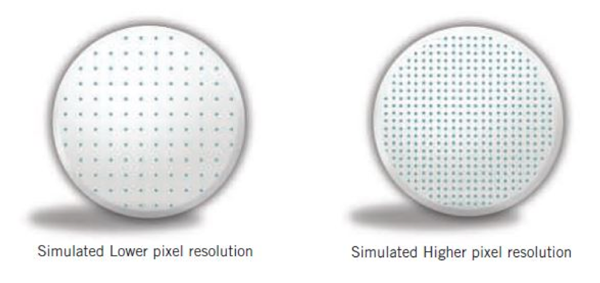

Comparatively, one can make an analogy of Free-form Optics to the quality of a digital camera. The higher the pixel count, the higher the degree of resolution it facilitates and the more precise the level of visual fine-tuning it permits.

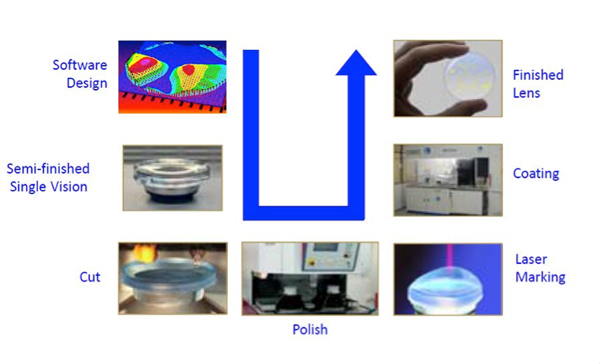

The Equipment

A Free-form generator uses industrial diamond cutters to rough-cut the lens and a single diamond point to complete the generating process. The lens is not ground in a Free-form generator; it is milled similar to the way a lathe would be used on wood so the machine essentially peels away the lens material.

The Free-form generator and its cutting tip are controlled by machine language known as CNC (computer numeric control). Wholesale laboratories like Expert Optics Inc., Luzerne Optical Laboratories, Ltd., Rite-Style Optical Co., and US Optical have free-form generators that use CNC technology.

Free-form generators use a precise diamond tool that cuts curves with a single point, much like those found in contact lens lathes. With the right kind of computer software, a single-point generator can reproduce virtually any complex multi-curve surface.

Free-form process

Free-form technology allows us to design customized lenses for our patients. Naturally, we need to take different and more precise frame measurements to allow the software designers to place optimum optics in the right places.

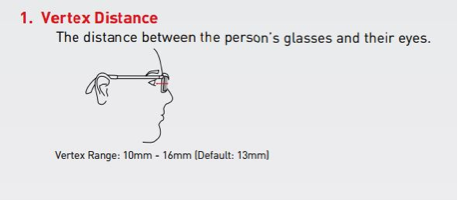

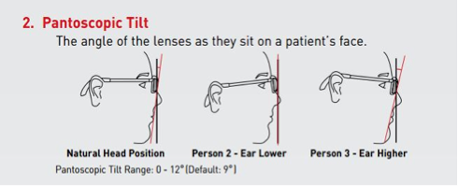

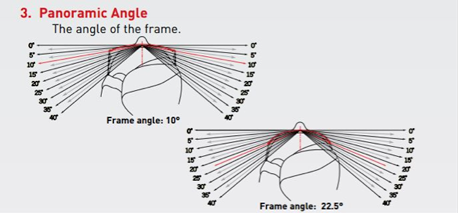

In addition to the frame measurements and monocular PDs and Seg heights; we need to consider the Position-of-Wear. Position of Wear (POW) is really a shorthand for describing how your patient’s fitted new frame has repositioned the lenses from the phoropter placement used in the exam room. Vertex distance, pantoscopic tilt, and face-form or panoramic angle measurements are needed to truly personalize the eyeglasses.

Once you are familiar with Free-form Technology and the latest developments, you may want to decide which company designs the best lenses for your patient’s requirements and works best for your office structure.

Now you are ready to educate your patient.

Benefits of Free-form Progressive Lenses

- Wider field of vision due to back surface design.

- Maximized visual acuity at all distances.

- Wider intermediate and near zones.

- Minimal visual "swim and sway."

- Low levels of unwanted astigmatism.

- Aspheric/atoric designs make the lenses thinner and flatter.

- Reduction of Higher Order Aberrations.

Imagine having the same experience with your glasses. Sure, you can probably see fine with the ones you have, just like watching analog TV was fine when that was all you had.

Your patients love their electronic devices and technology. Freeform lenses will allow them to enjoy each daily activity without restriction. Of course it will take more than one pair of glasses. And they will be amazed by the clarity and comfort.

When we are talking about Free-form lenses, we are mainly thinking about PALs. However, SV Freeform lenses really create the Wow-effect. They offer clear, natural and distortion-free vision all the way to the periphery of the lens.

Wherever you are with Free-form Technology right now, embrace it. It is the way of the future.

In my opinion, Free-form Technology is a gift to the American optician to re-establish ourselves as the knowledgeable professionals that we are.

Maggie Sayers is a professional development coach and a Master Optician. Her optical career started over 30 years ago in a family business in Germany.

Since she came to Florida in 1987, she has worked diligently to promote high professional standards in opticianry. Her mission is to help opticians achieve their personal success through serving the public as vision experts.

As a professional development coach Maggie provides education workshops that focus on leadership and personal engagement. Her time management course has inspired many participants to think outside the box, apply newly acquired knowledge and achieve extraordinary results.

Maggie's enthusiasm for opticianry is inspiring and her keen business sense paired with excellent communication skills make her a highly sought after motivational speaker.