| New Products |

|

|

| |

|

Operating Strategies |

|

|

Bob Niemiec |

Rx Suns Present Challenges

and Opportunities

While the current overall economic environment continues to be challenging for many retailers including those in the optical space, there are areas of opportunity. One of these is sunwear, and Rx sunwear in particular. A recent survey of optical retailers conducted by Jobson Research found that 54 percent of respondents said

Rx sun lenses as a percentage of total dollar sales had increased over three years ago. Additionally, nearly 75 percent of these optical retailers indicated that for at least the last two years polarized lenses made up an increasing portion of total lens sales. With the start of summer, sun and polarized lenses present even more of an opportunity.

Prescription polarized sunwear has always stood out as a smart second pair sale. Together with a fashion frame, Rx polarized lenses provide a great combination of style and performance. Although past generations of polarized lenses experienced occasional problems such as colors that didn't match due to inconsistencies in the polarized film itself, many of these issues have been addressed, making processing within the lab a much more “right the first time” experience.

Beyond prescription polarized, we are in a period of enhanced processing capabilities. For those who are aware of the advantages of the capabilities of equipment such as the MEI CNC edgers and some of the National Optronics edgers, processing high base curve lenses to accommodate higher style, wrap type frames presents a great opportunity for incremental sales and margin. Given that the purchasers of this type of high-style, high-performance eyewear are typically among the least price sensitive, the margin opportunities for those who can successfully supply this product in a consistent manner are great. However, to achieve this result requires investment beyond the cost of the machine. To unleash the real capability of this type of equipment requires investment in people who are understand the true capability and limitations of the machine as well as the relationship between these capabilities and the desired product outcome.

Merely investing in the equipment without the corresponding investment in people, training and process development will result in a less-than-optimal outcome. A lab that makes a sizeable capital investment in this machining technology without investing in training and process development has done nothing more than purchased a $250,000 edger.

By offering prescription polarized sunwear produced with enhanced processing capability and supported by proper training, labs have an opportunity to build a true competitive advantage. In the end, success comes not from doing the easy things well but from doing the difficult things well that people want and are willing to pay a premium for.

—Bob Niemiec is president of Optinova Solutions, LLC, a consulting firm specializing in operations improvement, new technology assessment and mergers and acquisitions, primarily in the optical industry. An optical industry veteran, he has held senior level positions in manufacturing and distribution with large optical retailers and manufacturers. He can be reached at

[email protected]. |

| |

|

Tech Talk |

|

Walking Around De-block

De-blocking, the last step before inspection, removes the block from the lens so the lens can be cleaned and edged.

|

|

Surface Blocks courtesy of Precision Tool. |

Due to its relatively simple procedures, de-blocking can be overlooked as a source for spoilage. But de-blocking takes skill, time and care. Lenses can be cracked, chipped, scratched or warped if proper procedures are not followed. Improper de-blocking can damage not only the lenses, but the blocks as well, which will lead to increased spoilage.

Lab managers recommend taking sufficient time with de-blocking. You don’t want to hold up production of course, but rushing through the de-blocking process seems to be the biggest cause of problems. Cracking, chipping and scratching and other de-blocking related spoilage, are generally an operator mistake, and occur more often when the de-blocking process is done too quickly. Some labs run polish warmer than others, and these labs should allow for the lenses to cool prior to de-blocking.

De-blockers for alloy systems require hot water to melt the alloy blocking compound. If the water is too hot, the lens can warp, or if not filtered properly, the debris can scratch and chip the lens surface. Alloy-free or wax compounds snap off in the de-blocker, which avoids heat, but if too much pressure is applied the lenses can crack. Be particularly careful with plus lenses because their edges are so much thinner and are chipped and cracked more easily.

In order to save time, instead of using a de-blocker, some labs will use a de-blocking tube and manually de-block lenses. However, if the tube is dirty, the lens surface can be compromised, and applying too much pressure with manual de-blocking can snap the lens. Although surface-saving tape is recommend only for alloy blocking, some labs will use it for alloy-free blocking as well. In either case, if the wrong tape is used for that particular lens, of it is removed too quickly or without care, it will cause cracking and other imperfections on the surface of the lens at de-blocking. Check with manufacturers to verify the tape is the right type for specific brands and prescription powers. |

| |

|

HR Corner |

|

Nine Effective Management Techniques

Almost everybody thinks they are a good manager, and owners or partners of an eyecare practice are no exception to the rule. If you are curious about how you stack up, determine which of the following characteristics listed below describe your management style. You might be surprised to learn how many of these techniques you should be using in order to run a smooth practice.

Communicate the big picture.

If you want your employees to work hard and be committed to your business, you must to keep them in the loop. Open communication helps foster loyalty and gives employees a sense of pride. It helps them understand how their work contributes to the company's success. Set up a regularly scheduled meeting to inform your employees about new business developments, new product offerings and answer any questions.

Delegate work and responsibilities.

Share your workload and delegate projects according to people's strengths, and let employees develop their own good work habits and leadership skills. Before you take on a project, try to get into the habit of asking yourself if one of your employees can handle it instead.

Help employees set goals.

Setting deadlines and goals helps keep employees focused, busy and motivates them to do their work. Talk to each of your employees about your practice's goals, and work with them to set individual goals directly linked to your mission. Make sure each employee understands their professional growth path in the company.

Recognize problems.

It is impossible to know about every single personality conflict or other problems in the office. Stay tuned in to your employees so you can be proactive and resolve situations before they escalate. If you notice a change in an employee's work habits or attitude, try to get to the root of the problem before it starts affecting the rest of your staff.

Reward employees.

Everybody appreciates raises and bonuses, but monetary rewards aren't the only way to thank employees for a job well done. In fact the easiest way to recognize an employee's contribution—by simply saying “thank you”—is often the most overlooked. Whether you do it with words, money, an employee recognition program or other incentives, make sure your employees know you value their efforts and contributions.

Be a mentor.

As a business owner or manager, one of the greatest gifts you can give your employees is sharing your knowledge and experience. Showing your employees firsthand how you work with patients or forecast sales is far more effective than just talking them through it.

Give reviews.

Employees need feedback about their performance to improve their skills and grow professionally. Set up a formal review program and give performance appraisals at least twice a year. If you set goals and give performance reviews in the same meeting, make sure you spend equal time addressing past performance and future goals.

Have a heart.

Family emergencies, illnesses and other unplanned events always arise. Show employees some compassion by being flexible with work hours and time off so they can tend to important matters. Employees always appreciate a sympathetic ear, and as long as your business will not suffer, make every effort to accommodate employee needs.

Take the time to be a manager. During times when your practice is busy, do not forget to be a manager. Employees depend on your strength and guidance—especially when they are faced with new projects that require your time and input. Remember to give employees your undivided attention when they want to talk.

—Hedley Lawson brings over 25 years of optical industry experience to Jobson Medical LLC. For over 10 years, he has been a contributing editor to VM, most recently as writer of the monthly column “Business Essentials.” He is the Contributing Editor of VM's E-Newsletter

Business Essentials. |

|

|

Assessing Financial Performance,

Part 2

The cornerstone of assessing financial performance of the lab is the review and analysis of accrual basis financial statements. An accurate picture of performance cannot be achieved using cash basis reporting. Cash basis accounting is easier than accrual basis because it is like using a checkbook; every month all the deposits are added up to determine revenue and the checks written are added up to determine expenses. What's left over is profit. The biggest problem with cash basis reporting is that it reports last month's sales with the current month's expenses. It may also be problematic because some deposits may include receivables and some payables that are past due.

Accrual basis or double entry accounting records revenue and expenses in the period in which occurred. On this basis, a lab owner can judge whether the lab made a real profit or loss, compare one period financial performance to another and know exactly the level of assets, liabilities and equity. These statements should be prepared internally on a monthly basis in order to assess performance, give owners timely insight into the financial health of the lab and make quick adjustments to operations if a problem is discovered. Typically, the competitive companies in the industry prepare their internal financials within 10 to 15 days after the period ends.

Many labs use their accounting firms to prepare monthly financial statements. This works well, but only if they can complete the statements within the 10 to 15 day window. However, CPAs have multiple clients and therefore may not always be able to meet this timetable, especially during tax season. A qualified internal bookkeeper, even if only on a part-time basis, is vital to this timely reporting process. They should know how to properly complete the internal financials using accounting software, and also be able to make some reasonable estimates respecting transactions even if some information has not been received by the established cut off date.

Labs should, however, use their outside accountants to compile financial statements on a quarterly basis in order to discover any problems with the lab’s internal reporting and make suggestions on how the lab can improve performance. Other benefits from quarterly compilations include time reduction in preparing the final year end return, review or audit, and more accuracy in the payment of estimated income tax payments. The CPA can also advise the owners and bookkeeper on how to make reasonable estimates for monthly reporting purposes.

Read “Assessing Financial Performance, Part 1.”

—Jason A. Meyer is senior vice president, HPC Puckett & Company. Based in San Diego, Calif.,

HPC Puckett & Company specializes in mergers and acquisitions of wholesale optical laboratories. You can send comments or questions about this article or any other Dollars & Sense articles to Jason Meyer at

[email protected]. —Jason A. Meyer is senior vice president, HPC Puckett & Company. Based in San Diego, Calif.,

HPC Puckett & Company specializes in mergers and acquisitions of wholesale optical laboratories. You can send comments or questions about this article or any other Dollars & Sense articles to Jason Meyer at

[email protected].

|

|

| |

|

|

|

Essilor's Fontanet Eyes Synergies with Satisloh

Essilor's pending acquisition of Satisloh, announced earlier this month, will impact several levels of the optical industry, including manufacturers, wholesalers, retailers and eyecare professionals. However, its effect will be felt most strongly by prescription laboratories.

Essilor executives said they plan to leverage the complementary capabilities of the two companies to provide labs with a “total solution” for ophthalmic lenses and lens processing equipment while growing the overall market. Essilor chief Xavier Fontanet stressed that the company's major goal is to “grow the industry via the growth of sophisticated products.”

In an exclusive interview with

Vision Monday, Essilor chief Xavier Fontanet discussed Satisloh's strategic importance to Essilor and why he believes it will enable Essilor to expand its international business while growing the optical industry at large. He characterized the Satisloh acquisition as a “deep investment” with considerable long-term payoff for Essilor in terms of servicing existing customers, opening up new markets and fast-forwarding new technologies.

“This is a very big move—the R&D of Essilor and R&D of Satisloh will generate better machines and products for everybody,” said Fontanet. “If the global market grows even one percent, it has a huge effect on Essilor's value…We think of Essilor, but we also think of the industry as a whole, because [this combination] is beneficial.” |

| |

|

|

|

High-Myope Gets a Sporting Chance

“We received a single-vision polycarbonate Transitions order: R: -10.00D, .25 @ 96, L: -17.00D, 1.5 @ 100. Decentered 6.5 each eye.

“The most difficult part was that our customer requested them inserted into a Hilco sport frame which we were able to complete with a special bevel placement and then with a special cutter for the Optronics edger. The prescription came out perfect and the customer was thrilled with the way the Rx looked even though it was still a bit thick near the temples.”—Jeremy Gnade, president,

Sunburst Optics, Syracuse, N.Y. |

|

| |

|

|

Debi McGrath of QC Optical

With over 45 years of experience, Debi McGrath is truly an optical veteran. McGrath began her optical career when she was only 14 years old, pulling lenses at Nassau Lens West in Van Nuys, Calif. Fourteen years and three laboratories later, McGrath found her favorite job in optical. With over 45 years of experience, Debi McGrath is truly an optical veteran. McGrath began her optical career when she was only 14 years old, pulling lenses at Nassau Lens West in Van Nuys, Calif. Fourteen years and three laboratories later, McGrath found her favorite job in optical.

“For 15 years, I had my dream job working in Santa Clarita, Calif. for Dr. Michael Corben, OD,” McGrath said. As the only employee with lab experience, McGrath ran the on-site finishing lab all by herself. “It was three miles from my house, my son was in school and I didn't have to work with people and personalities. It was a great break from what I was used to,” McGrath commented. “The job was about more than just money,” she remarked. McGrath said she cared about each patient in the practice and would go to any cost for patient comfort.

In 2006, McGrath made the difficult decision to leave this dream job in Southern California and move to Oregon to support her son by putting him through college. “By becoming a resident of Oregon, I was able to send my son to Oregon State University debt free,” she said. When she finalized her decision to move to Oregon, Keith and Neil Grossman, whom she previously worked for at Empire Optical, a wholesale lab in North Hollywood, Calif. called and recommended McGrath to Jim McAndrews at

QC Optical, an independently-owned wholesale lab in Portland, Ore. “Jim hired me without even meeting me based on that recommendation alone,” McGrath said.

As bench supervisor at QC Optical, McGrath is responsible for final inspection, turnaround time, quality of work and answering questions if someone is unsure of how to do something. “It's more about troubleshooting and having a team of people who hold themselves accountable,” McGrath said. “I have three people on my crew who know what they're doing and make me look really good.” For this reason, McGrath makes sure to let them know they are appreciated. Her technique has been effective, as QC Optical's return rate percentage is less than two percent.

McGrath holds firmly to the belief that if you're going to be somewhere for the better part of the day, you need to enjoy it. “I work for two great guys who really care about our team. Whenever something happens, they encourage us to take care of ourselves and assure us our job will always be there.”

McGrath plans to retire from QC Optical in five years to pursue her goal of opening a bed and breakfast. She and her brother-in-law plan to start this business venture together on the outskirts of Portland. Although QC Optical has been supportive of her goals, they would love to keep her. “Anything can happen between now and then,” she said. “We'll see what's in the cards.”—Samantha Toth |

|

| |

|

|

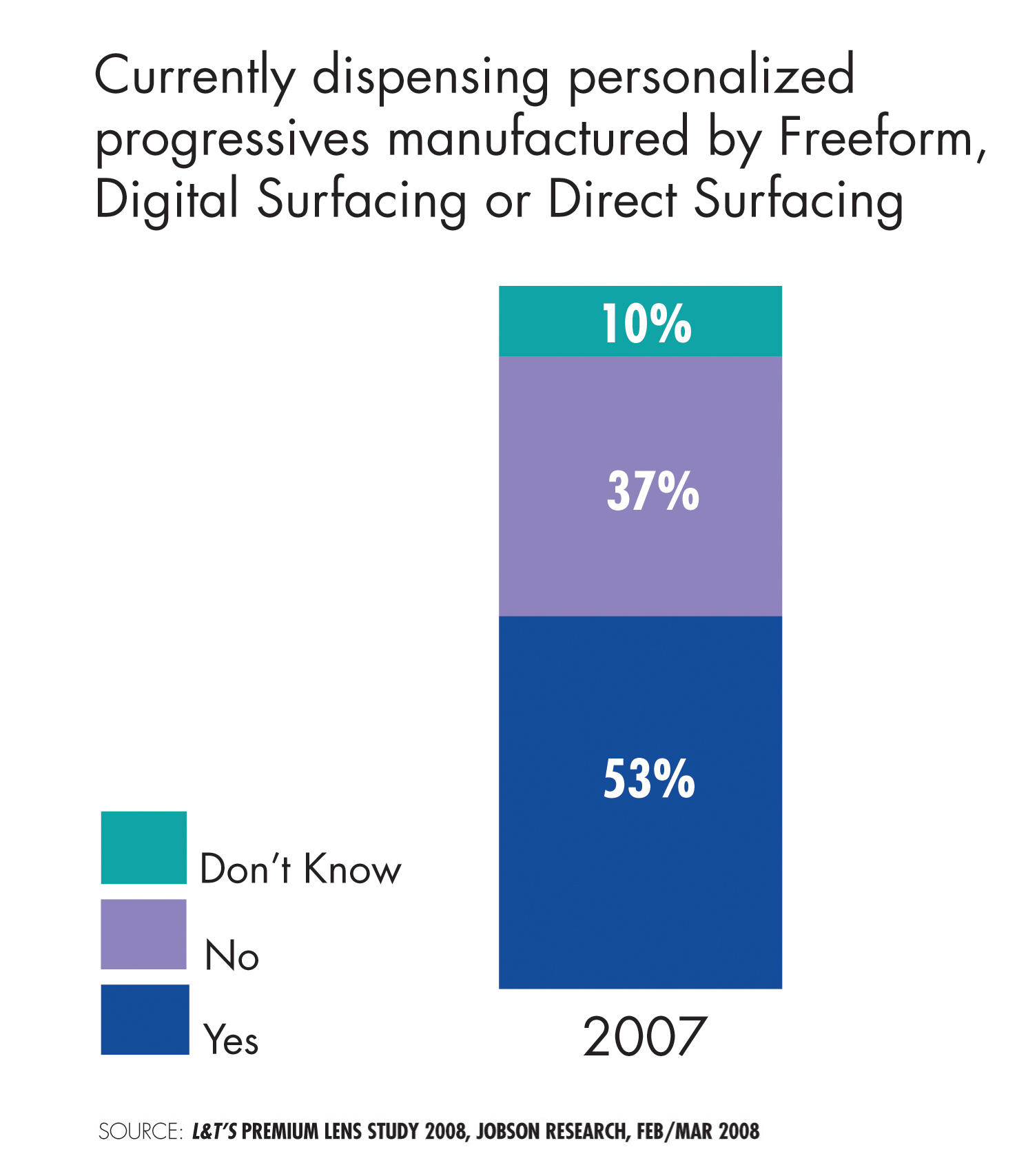

Lenses by the Numbers, Part 2

Last month, we examined trends in ophthalmic lens sales as reported in L&T's 2008 Premium Lens Study of Eyecare Practitioners, a market research survey conducted by Jobson Research. This month, we look at additional findings from the survey that pertains to lens materials and treatments.

Lens Materials

When asked to rank lens material by popularity, standard plastic was ranked 1 by almost half (44 percent) the retailers. Polycarbonate was ranked 1 by 40 percent. Glass was ranked least popular by the most retailers (69 percent).

Sixty five percent of retailers say that their 2007 polycarbonate lens sales increased as a proportion of total lens pair sales compared to 2006. Sixty six percent say that their sales of high index lenses had grown since 2006, and 38 percent say Trivex sales had increased over the last year.

Fifty two percent say that their mid-index lens sales had stayed flat. Glass was the worst performer, with 59 percent saying glass made up a smaller proportion of their total lens sales in 2007 than in 2006.

High-Index Lenses

When asked to rank high-index lenses based on popularity, 46 percent ranked 1.67 as most popular and 41 percent ranked 1.60 as most popular. Comparatively, 1.74 was ranked least popular by 65 percent of retailers.

Lens Treatments

An impressive 86 percent of retailers surveyed say that they had experienced an increase in AR lens sales as a proportion of total lens sales in 2007 vs. 2006. 73 percent saw an increase in polarized lenses and 72 percent saw and increase in photochromic sales over the same period.

For 42 percent of retailers surveyed, tinted lens sales stayed about the same versus the year before.

63 percent of retailers say they offer two different price points for AR lenses—one being standard, the other being premium.

“Read Lenses by the Numbers, Part 1.” |

| |

|

|

Zeiss, VSP Acquire Tri-City Optical Lab—Carl Zeiss Vision has added Tri-City Optical to its network of U.S. laboratories. The company acquired the independently-owned Clearwater, Fla. wholesale lab in partnership with VSP Vision Care, with Carl Zeiss Vision as the majority shareholder. The purchase price was not disclosed.

“We are very excited to have Tri-City as part of Carl Zeiss Vision's laboratory network,” said Fred Howard, Carl Zeiss Vision’s president, the Americas. “This will enhance our ability to support Florida eyecare professionals with outstanding laboratory services and advanced products like GT2 Progressive Lenses by Zeiss, Carat Advantage and Teflon Clear Coat Lenses. Tri-City has the capabilities, experience and reputation that will help us to grow in this key market.”

Commenting on the significance of the move for VSP, Don Oakley, VSP vice president of ophthalmic supply chain and services, said, “This development will benefit doctors and their patients in the Southeast by offering enhanced choices for high quality products and services. Working together with valued suppliers like Carl Zeiss Vision is part of our ongoing focus on strengthening the eyecare delivery system for private practice.”

The Tri-City acquisition marks the second time Zeiss and VSP have partnered in an optical lab purchase. Last year, the two companies each acquired a stake in Perfect Optics in Vista, Calif. VSP chairman Rob Lynch stated at that time that VSP would pursue other lab acquisitions in partnership with vendors and on its own.

Founded in 1993, Tri-City serves independent eyecare professionals in Central Florida and beyond. Carl Zeiss Vision confirmed that Richard Hoerbelt and his management team will remain in place, and no business process changes are contemplated.

“We chose Tri-City in part because of the excellent service the lab provides to its customers,” said Claude Labeeuw, Carl Zeiss Vision’s vice president, business development. “Our goal is to maintain that service while providing Tri-City customers with outstanding new product options.”

VSP Legends 4.0 Opens Teflon Coating Facility—

VSP Legends 4.0 optical laboratory recently opened an onsite Teflon lens coating facility. The VSP-owned lab, located near Dallas, services private practice eye doctors throughout the U.S.

|

|

The hardcoating system is an integral part of the new Teflon AR coating facility at Legends 4.0 Optical. |

|

|

A lab technician loads lenses into the Teflon coating chamber. |

“Onsite application of Teflon coatings at VSP Legends 4.0 gives private-practice doctors an attractive option to reduce delivery times for this high-quality product,” said Don Oakley, VSP vice president of ophthalmic supply chain and services. “Working together with valued suppliers like Carl Zeiss Vision, VSP is dedicated to strengthening the eyecare delivery system by expanding choice, increasing value and speeding delivery.“

Developed by Carl Zeiss Vision in collaboration with DuPont, Teflon Clear Coat anti-reflective technology produces lenses with high luminous transmittance, scratch resistance equivalent to a premium hard coating, and a super-hydrophobic, oleophobic coating for easy cleaning.

Teflon Clear Coat lenses offer “the premium performance of Teflon Clear Coat Lenses, combined with VSP Legends 4.0's outstanding service is an exciting development benefiting both doctors and eyewear consumers,” said C.J. Hartmann, Carl Zeiss Vision's brand manager for coatings.

VSP operates three wholly-owned optical labs located near Sacramento, California; Columbus, Ohio; and Dallas, Texas.

Essilor Offers New Crizal Coater to Independent Labs—

Essilor is introducing its new spin backside mithril coating unit (S-BSM), expanding the opportunity for Crizal in-house processing to smaller independent Varilux/Crizal laboratories. Benefiting from a reduction in facility and construction costs due to diminished clean room requirements, while maintaining Crizal product performance standards, there are currently four independent lab sites under contract. The machine features a 25 sq. ft. footprint, and has a capacity of producing 18 jobs per hour with a 96 percent yield. No second pass is necessary. Cycle time is nine minutes (in-machine post cure is required). Only Essilor polycarbonate and Orma lenses can be coated. The machine can also coat bifocals and trifocals.

Bruce Sauer, Founding Manager, VSP Lab Dies at 69—Bruce Sauer, who founded VSP’s Sacramento-based laboratory, died of liver cancer on May 10. Sauer, 69, died peacefully at home in Sacramento accompanied by his wife Nicki and their sons, Christopher and Eric.

|

|

Bruce Sauer |

As the founding manager of the

VSP Lab, Sauer was instrumental in the development of VSP's laboratory business. He started his career in the optical industry working for American Optical in the San Francisco Bay area. In 1972 he was hired by VSP's first president and CEO, John O'Donnell, to start the first VSP lab. Sauer, in turn, hired many of the people who built the facility into one of the industry's premier labs.

Sauer retired in 1999 after 27 years at VSP. After retiring, he spent his time traveling to Italy and restoring classic wooden boats. His award winning creations have been shown in the annual Lake Tahoe Classic Boat Show.

“Bruce will be remembered for his personal warmth, integrity and humility. He helped to create an employee-friendly culture that lives on today,” said Jack Banville, managing director of the VSP Lab in Sacramento.

Remembrances may be sent to the Sauer family, care of Jack Banville, VSP Optical Lab, Sacramento, Calif., 95827.

Chadwick Launches Line of Visual Aids for Hemianopia—

Chadwick Optical in White River Junction, Vermont, is introducing a line of visual aids for the hemianopic population. Hemianopia is a visual condition resulting from stroke, TBI (traumatic brain injury) or brain tumors where the patient is blinded in either the right or the left sides of both eyes. This condition causes difficulty in mobility.

An article in the May 2008 issue of the

Archives of Ophthalmology reported the findings of the 2004-2005 multi-center clinical trial testing these mobility aids; the “EP"-Horizontal, or the Peli Lens. Entitled “Community-Based Trial of a Peripheral Prism Visual Field Expansion Device for Hemianopia” the paper reported that 74 percent of subjects continued to wear the aids at the end of the study, and 47 percent were still wearing them at 12 month follow up. These aids expand the field of Hemianopes 20 degrees using high power prisms positioned in a unique configuration. The concept was developed by Dr. Eli Peli of the Schepens Eye Research Institute, Harvard Medical School, in 2000.

A new clinical trial is currently underway to test an improved version of the aid which expands the visual field to 30 degrees. Details of where hemianopes may participate in the new study are available at

www.clinicaltrials.gov (clinical trial NCTO0494676). | |

|

|

|

Stainless Steel Spark Resistant Production Vent Hood (#15004)

Manufacturer: BPI

Description: Vent hood designed to reduce odors and sparks

Target Customer: Finishing labs

Features/Functions: Hood is designed to help eliminate odors associated with dyeing and neutralizing plastic lenses. It is spark resistant to reduce number of ignition sources for chemicals used near or above their flash points. Vent hood contains two built-in polychromatic (chroma-type) fluorescent lamps, which are sunlight color-balanced for color matching by reflected light. Exhaust blower included.

Size/Weight: 49 inches high by 51 inches wide by 28 inches deep

(800) CALL-BPI

www.callbpi.com |

| |

|

Varilux Sport Lenses

Manufacturer: Essilor of America

Description: Tinted sport progressives

Target Customer: Active customers who need progressives

Features: Progressive lenses designed specifically for use during sports to provide natural and precise vision. Available in six different shades. Polycarbonate material features lightweight lenses, impact resistance and protection from UV light. Uses Crizal Sun technology.

Essilor of America is introducing Varilux Sport lenses, progressive lenses designed specifically for use during sports to provide natural and precise vision. The lenses offer an extra large far distance field, instant immediate vision and a stabilized near vision area. Available in six different shades, from yellow to dark brown, patients can choose the best lens for their desired sport. The polycarbonate material used giving wearers a light lens with impact resistance and protection from UV light. The lenses also filter blue light, the visible radiation that creates a veiling glare, and focuses in front of the retina to create a blurred image. They also feature Crizal Sun technology, which prevents backside reflections while preserving the original color of the lens, as well as resists scratching and cleans easily.

The six different lenses are named after different types of wind. The Breva is a yellow polarized category 2 lens that offers 30 percent light transmission, while the Squamish is an orange fixed tint category 2 lens offering 37 percent light transmission. Santa Ana is an orange brown fixed tint category 2 lens that offers 24 percent light transmission, the Skiron is a brown polarized category 3 lens that offers 12 percent light transmission and the Lombard is a brown fixed tint category 3 lens that also offers 12 percent light transmission. Finally, the Williwaw is a dark brown fixed tint category 4 lens that offers five percent light transmission for extreme environments.

Lenses are available in ranges -8.00 to +6.00D, cylinder 4, add 0.75 to 3.50 and diameters mini 60/65, maxi 70/75, depending on version.

(800) ESSILOR

www.essilorusa.com |

| |

|

SR-91 Freestyle Progressive Polarized Lens

Manufacturer: Kaenon Polarized

Description: Progressive polarized lenses

SR-91 Freestyle Progressive Polarized Lens

The SR-91 Freestyle Progressive Polarized lenses from Kaenon Polarized offer the precision and flexibility of back-side digital surfacing available in a wrapped polarized progressive lens in 6.25 and 8.25 base curves in the company’s patented SR-91 lens material. The new lenses can be prescribed for Kaenon brand frames or any other frames to give customers a lens customized to the optical accuracy of 0.01 diopters, exceeding that of standard PALs offered only in 0.25 diopters. This accuracy gives wearers a smoother and wider field of vision, a significantly lower rate of non-adaption, less head and eye movement as well as perfect vision up close, mid-range and far away, according to Kaenon. The SR-91 material also makes an extremely lightweight and thin lens that offers impact resistance that exceeds standards set by ANSI Z.87.1.

Kaenon's proprietary polarized lens technology features the combination of SR-91 and the Glare 86 Polarizing Element. Kaenon’s lens manufacturing process encapsulates the Glare 86 element within the SR-91 lens material. The molecular bond between the two materials is so strong that Kaenon is able to offer a lifetime guarantee against cracking, splitting and delamination. Glare 86 not only eliminates glare, but it also houses SR-91's purpose-built tints and Kaenon's proprietary Light Transmission Control (LTC) technology, giving every SR-91 lens the ability to regulate the amount of light transmitted to the eye. This control in polarization gives Kaenon the ability to calibrate SR-91 for use in different light conditions—from low light to full sun—or customize the lens tint and light transmission level to the wearer's specific desire. Lenses are available in three specific tints: gray, copper and yellow.

Features: Precision and flexibility of back-side digital surfacing in progressive lens with 6.25 and 8/25 base curves. Optical accuracy of 0.01 diopters. Impact resistance that exceeds ANSI Z.87.1 standards. Lightweight and thin lens.

Availability: Progressives

(949) 574-7918

www.kaenon.com |

| |

|

|

Polycore SunSensors HPC

Manufacturer/Distributor: Corning/Polycore

Description: Next-generation photochromic lenses featuring new high-performance coating (HPC) developed by Corning and Tokuyama.

Features: High clarity and 100 percent UVA and UVB blocking. Achieves one of the highest levels of performance on the market for darkening and fading speed, changing from a gray dark state transmission of 11 percent to 65 percent transmission after only five minutes of fading time.

Availability: Polycarbonate semi-finished single-vision and progressive lens designs in gray and brown.

(888) 645-7788

www.polycore.com |

| |

|

Continua SVSF Lenses

Manufacturer/Distributor: Vision-Ease Lens

Description: 80mm semi-finished single vision lenses

Target Customer: Customers who need customized lenses to fill a high-plus or high-minus prescription.

Features/Functions: The new Continua lenses from Vision-Ease meet the need for direct-surface progressive lens processing and lenses for wrap-around frames and larger frame styles. Continua SFSV 80mm lenses are available in a number of base curves. With a prescription range of +8.00 to -12.00D, these lenses accommodate a variety of consumer needs. Highly abrasion-resistant thermal-cured hard coating; compatible with all AR coating applications. Backside tints to sunglass state; provides 100 percent protection from UV rays.

(800) 328-3449

www.vision-ease.com |

| | | | |

| In This Edition...

|

| |

|

•

Subscribe to Lab Advisor

The monthly update for Optical Laboratory Owners and Managers

•

Forward this issue of Lab Advisor to a friend or colleague

•

Print this issue of Lab Advisor

•

Stay on top of optical industry news!

Subscribe to our other

e-newsletters:

•

VMail Extra

•

Business Essentials

If you have lab news or want to share information about technical topics, please

contact us.

Or

contact

Andrew Karp,

Editor-in-Chief

Visit

LabTalkonline.com for additional articles of interest about labs. |

| |

| |

|

| |

LabTalk Spotlight

June 2008

Since the introduction of drilled rimless compression mounts there have been many advancements in rimless eyewear fabrication and adjusting techniques including the removal, replacement and adjustment processes. In the May/June issue of LabTalk, “Drilling for Better Results” by Bob Woyton of Hilco provides Tricks of the Trade for removal, assembly, and making adjustments.

Check out this tip for removal for safely removing compression sleeves without risk:

“There are instances in which assembled mounts need to be separated and replaced. It could be to change the Rx, replace a faulty mount or change a broken frame component. To safely remove the compression sleeves without risk of damaging the lenses or frame, compression removal pliers are recommended.

Trick of the Trade

“Before attempting to remove the hardware, cut the bushing at the point that bridges the two sleeves together. This makes removal much easier. Place the compression removal pliers between the frame hardware and lens and squeeze the pliers to pry apart. The pliers are designed with a smooth form to reduce the risk of damaging lenses. Also, if positioned properly the frame finish will not be scratched. Sometimes it’s necessary to rock the pliers a little to separate completely. If you are going to reuse the lens, use the Rimless Punch to remove the bushings from both sides of each lens. Simply push both the prongs through the lens holes to ream out the debris left inside the lens holes.”

To read the entire article, “Drilling for Better Results” log on to

http://www.labtalkonline.com/. Here you will find the article in the Archives section, under Lab Operations, May/June 2008.

|

|

Buying Group & Lab Association News

Optical Resources to Launch New Web Site—Optical Resources is launching a new Web site July 1. According to Josh Halstead, general manager, the site will provide members with a quick and easy way to access vendor product and pricing information, Optical Resources publications and incentives.

“Members will be able to access all this information and more through a Members Only section located at

www.opticalresources.net,” Halstead told Lab Advisor. “Later this year Optical Resources will be launching a lab message board in the Members Only section where members will be able to network and share information. Optical Resources' goal with the message board is to help the independents remain so by partnering with other Independents,” Halstead noted.

Optical Resources will hold its annual meeting in Indian Wells, Calif., January 7-11, 2009. Members will have an opportunity to meet one-on-one with Optical Resources participating vendors, network and learn how to grow their business.

| |