PROTECTING OUR AMAZING EYES

High-Performance Eyewear Technology for Sport, Safety and Everyday Use Sunwear

By Deborah Kotob, ABOM

Release Date: June 1, 2018

Expiration Date: June 14, 2023

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Understand that the "Eye Protection" conversation applies to all of us from children to high-performance athletes.

- Learn about technological advancements and pioneering efforts that improve high-performance eyewear.

- Learn the many steps to excellence in the crafting of lenses: surfacing, coating and finishing.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Technical Level 1 Course STWJHI688-1

We have entered the age of the Experience Consumer. Today's consumer is looking for lifestyle enhancing products. They are interested in buying eyewear that improves their experience whether driving, cycling, boating or just hanging out at the beach. Technology-enhanced performance of eyewear is a driver for their purchase. And just as the Experience Consumer chases technological improvements in their smartphones, tablets and other electronic gadgets, they expect their high-performance sport eyewear and sunglasses, and even their clear dress pair to feature the latest, most advanced optical technology. As eyecare professionals, we must also make sure they are aware that their high-performance sun and sport eyewear must also include the highest level of sun and impact injury protection available.

We have entered the age of the Experience Consumer. Today's consumer is looking for lifestyle enhancing products. They are interested in buying eyewear that improves their experience whether driving, cycling, boating or just hanging out at the beach. Technology-enhanced performance of eyewear is a driver for their purchase. And just as the Experience Consumer chases technological improvements in their smartphones, tablets and other electronic gadgets, they expect their high-performance sport eyewear and sunglasses, and even their clear dress pair to feature the latest, most advanced optical technology. As eyecare professionals, we must also make sure they are aware that their high-performance sun and sport eyewear must also include the highest level of sun and impact injury protection available.

We can uncover their eyewear needs and direct their eyewear purchases according to their lifestyle by asking a few simple questions to get the ball rolling. How much time do they spend outdoors, are they active in sports, do they drive, have they ever been bothered by glare when driving? It involves a bit of sleuthing to uncover all of their visual needs.

Sports and outdoor enthusiasts are particularly keen on having the very best technical enhancements in their eyewear. They are looking for performance-enhancing features. And the overriding motivating factor for sports enthusiast is style and performance, not cost, as evidenced by the high cost of gear for the cyclist or golfer, for example. Performance eyewear is an integral part of their gear and important to their game. Their experience when cycling, hiking, mountain climbing or simply driving can be enhanced with high-performance eyewear.

Where do we turn for the most technologically advanced high-performance sport eyewear? This is a real pain point for us opticians. We are aware of the optical limitations posed by the wrap angles in base 8 frames, and most opticians have experienced problems with lens retention in high wrap frames. Imagine for a moment that sitting at the dispensing desk is a high-performance athlete—let's say it's the Iron Man triathlete Peter Reid. Where do you turn when you want to provide the finest high-performance sport frames and goggles for someone who will consecutively swim 2.4 miles, then bike 112 miles and then run a marathon of 26.2 miles? For this, you need a state-of-the art lab capable of crafting precision optics in high-performance frames, shields and goggles with complex wrap designs and intricate bevels. And don't forget the high-performance coatings: super-hydrophobic AR, mirror and antifog. Only labs that have dedicated years to research and development and advancement of high-performance eyewear production through specialized digital design, surfacing, finishing and coating technologies can create the finest high-performance sun and sport eyewear. For our customers who enjoy active/sport outdoor lifestyle, the eyewear/sunglass solutions are sport-specific lenses and frames. Sport-specific eyewear is typically lightweight and impact resistant with excellent coverage requiring wrap frames with a high base curve. It requires experience and expertise to craft eyewear in high wrap frames due to optical issues, lens thickness and retention challenges. By utilizing proprietary digital design technology, the best optics and desired prescription can be achieved through digital lens optimization and wrap and prescription compensation.

Technological advancements in frame and lens design, surfacing, materials, coatings and finishing have improved optics and comfort for high-performance eyewear and dress eyewear alike. We will review these advancements and how they enhance optics and visual comfort for the wearer.

Technological advancements in frame and lens design, surfacing, materials, coatings and finishing have improved optics and comfort for high-performance eyewear and dress eyewear alike. We will review these advancements and how they enhance optics and visual comfort for the wearer.

In this course, you will be introduced to one of the innovators in performance eyewear solutions, iCoat. Through extensive research and development, they have contributed to the advancement of proprietary coatings and lens design for high-performance sun and sport eyewear. Their state-of-the-art freeform lens surfacing and lens edging, and finishing equipment produces state-of-the-art high-performance sunglasses and sport eyewear for athletes worldwide.

But first, a discussion about the importance of helping your customers protect their amazing eyes.

PROTECTION

The most important conversation we can have with our customers, especially our athletic customers, is one that educates them about all the ways to protect and preserve their eye health. Ideally, the conversation is initiated by the doctor during the exam where the risks associated with impact injury are discussed along with sport-specific eyewear requirements. Also, UV and HEV light exposure risk is explained including the fact that protection is needed even on cloudy days and should start young. The patient interprets the doctor's recommendation as medical advice, and when the doctor writes a separate prescription for sport and sunwear, it imprints on the patient as very important.

As opticians, we have to learn about the customer's lifestyle and health and family history to determine their eyewear needs and provide tailored solutions. For example, a person with a family history of age-related macular degeneration or someone who has undergone cataract surgery is in a higher risk category for sun damage to their retina and should take extra care to avoid sun exposure. Every customer deserves to be informed about the importance of protecting their eyes from sun damage and impact injury. For us to communicate effectively and confidently, it is vital that we understand the hazards posed by environmental light exposure and the prevalence of avoidable impact injury. Think of yourself as your customer's vision and eye health advocate and high-performance eyewear expert.

THE HARMFUL EFFECTS OF SUNLIGHT ON OUR AMAZING EYES

Sunlight is essential to life and sight but there are harmful rays that penetrate the earth's atmosphere which can damage our eyes and the skin. These harmful rays are not necessary for vision. It is recommended that we prevent exposure and the correlated damage from these rays with the use of protective sunwear.

You will hear light referred to in nanometers (1 billionth of a meter). This is a measure of the wavelength (the distance between two crests in the wave). The shorter the wavelength, the higher and more damaging the energy contained in the wave.

Actinic rays, aka ionized radiation, reach us in the form of UVB, UVA and HEV (high-energy visible) rays. They are the shortest wavelengths absorbed by the cells of our eyes and skin. When absorbed by the skin or the eye, these wavelengths can produce harmful effects. The harm is not always immediately apparent like sunburn on our skin or photokeratitis, a sunburn of the conjunctiva/cornea of the eye. Chronic sun damage occurs over time and can't be seen or felt in the eye, and often goes undetected until the irreversible damage is incurred that results in permanent vision loss. Actinic rays consist of invisible ultraviolet rays and visible short wavelength violet/blue rays. Actinic rays are those wavelengths capable of causing a harmful photochemical reaction in biological cells of skin and eyes. They can produce acute temporary or chronic permanent and cumulative oxidative damage. When UVA is absorbed by our skin, essential vitamin D is produced, but exposure durations must be kept short to avoid UV damage to the skin, including melanomas and premature aging.

Exposing our eyes to UV rays is associated with the formation of cataracts, pterygiums, pingueculas (unsightly permanent growths in the cornea and conjunctiva) and cancer of both the eyelids and the eye itself. Visible light is essential for sight, but our eyes need protection from short wavelength visible violet/blue light. HEV light has been implicated in retinal damage and is cited as a possible contributing factor to the development of age-related macular degeneration (AMD), an incurable and blinding retinal disease that causes central vision loss.

HEV short wavelength visible violet and blue wavelengths are the only visible waves that scatter in the environment, which impedes vision by producing glare, loss of contrast sensitivity and loss of detail. When these wavelengths of light scatter inside the eyes, they can also result in veil illuminance, which interferes with sharp, clear vision and contrast sensitivity. Therefore, minimizing short wavelength violet/blue wavelengths of light protect not only the eyes but also improves vision.

Note: In addition to protecting the eyes from solar blue light, minimizing short wavelength (violet/blue light) scatter in our clear dress eyeglasses reduces eyestrain resulting from the blue light scatter related blur experienced when viewing digital device screens. When a lens reduces scattered blue light transmission to the eye, it improves contrast sensitivity meaning that details are sharper and edges more clearly defined. For our clear indoor pair of eyewear, there are new blue filter AR coatings to help reduce eyestrain associated with the blue light emitted by digital device screens, e.g., smartphones and tablets.

Protecting the eye from the damaging effects of sunlight is vital for the preservation of our vision and eye health. The best protection requires sun protection and impact protection.

SUN PROTECTION

Sun protection includes coverage/wrap, backside UV AR, mirror coatings, blue filters, UV400 protection and blinding glare protection. The eyes are most vulnerable to sunlight between the hours of 8:00 a.m. and 10:00 a.m. and between 2:00 p.m. and 4:00 p.m. when the UV angle of incidence results in a maximum level of exposure to our eyes.

Sun protection includes coverage/wrap, backside UV AR, mirror coatings, blue filters, UV400 protection and blinding glare protection. The eyes are most vulnerable to sunlight between the hours of 8:00 a.m. and 10:00 a.m. and between 2:00 p.m. and 4:00 p.m. when the UV angle of incidence results in a maximum level of exposure to our eyes.

It is important that sunglasses provide broader UV protection than the ANSI/ISO standard of UV380nm. Dark lenses without UV400 protection allow more UV to enter the eye since our pupils dilate more behind dark lenses.

- Both UV dyes dispersed in the lens during casting and mirror coatings reduce UV radiation transmission (the darkness of the tint does not have any effect on UV protection).

- UV travels directly to the eye but also scatters in the air and reflects from objects in our environment including from the back of lenses. Backside UV AR minimizes this issue.

- Blue light (HEV) protection in tinted sun lenses is enhanced by adding the yellow and orange to the base tint color; these colors naturally inhibit visible violet and blue light transmission through the lens.

- iCoat highly recommends polarized sun lenses for protection from blinding glare and increased visual comfort for the wearer. Polarized sun lenses strongly filter horizontally reflected light, the primary contributor to blinding glare. Protecting the eyes from blinding reflected glare improves the visual performance for athletes who need sharp unobstructed vision. Polarized lenses are the best when outdoors in highly reflective environments such as on the water, snow or sand. And they are the absolute best for driving. According to a study on pedestrian safety by the Department of Transportation, drivers have a 40 percent quicker reaction time when wearing polarized lenses versus tinted lenses. Those who enjoy water sports and fishing appreciate the reduction in glare on the water which allows them to see beneath the water's surface.

IMPACT PROTECTION

Protective sport eyewear: As their trusted optician, it is your responsibility to assure that the eyewear dispensed is appropriate for the planned purpose, e.g., sports and safety.

More than 90 percent of all sports-related eye injuries can be prevented with the use of protective eyewear explicitly designed for the sport, according to the Coalition to Prevent Sports Eye Injuries. Glasses, goggles, face shields and helmet attachments offer kids protection from eye injuries during school sports and physical education classes. Protective eyewear meeting ASTM guidelines when properly fit can mean the difference between safety and an eye injury. More than 40 percent of eye injuries are sport/recreational activity related. The AOA reports that among all eye injuries reported in the Eye Injury Snapshot, more than 78 percent of people were not wearing eyewear at the time of injury. And roughly 40,000 injuries result in legal blindness in the injured eye.

The National Eye Institute cites eye injuries as the leading cause of blindness in children in the United States, and most injuries occurring in school-aged children are sports related. The report also states that currently, most youth sports leagues do not require the use of eye protection.

Only eyewear marked with ASTM approval for a specific sports activity should be used in the production of sport eyewear (F803 standard for sport eyewear intended for racquetball, squash, handball, tennis, women's lacrosse and badminton, F910 for baseball and F513 for hockey).

Protective safety eyewear: American National Standards Institute (ANSI) impact resistance standards require that the lenses, regardless of thickness, pass impact resistance tests. ANSI established safety eyewear standards:

- Z-87 basic impact guidelines for safety eyewear lenses requires a 3.0 mm minimum lens thickness regardless of material. Drop ball test must withstand the impact of a 1-inch steel ball drop from 50 inches.

- Z-87+ high impact standard for safety eyewear lenses requires minimum 2.0 mm thickness and withstand the impact of a one-quarterinch ball traveling at 150 feet per second.

- Z-87+ high impact standard applies to all safety frames.

What are the current technologies available to improve optics and comfort and provide protection for both high-performance sunwear, safety and dress eyewear?

HIGH-PERFORMANCE EYEWEAR FOR THE EXPERIENCE CONSUMER LIFESTYLE

The following introduces you to the multilayered process and advanced technology employed by iCoat in the crafting of high-performance eyewear. They are experts who understand the Experience Consumer's demand for style, sharp vision and protection in their high-performance eyewear.

STATE-OF-THE-ART SURFACING (including high base curves and in all materials)

STATE-OF-THE-ART SURFACING (including high base curves and in all materials)

State-of-the-art digital design software computes the optimal lens surface topography to produce the best vision based on frame features and fit (vertex, wrap angle and pantoscopic tilt, aka position of wear measurements) along with the prescription, starting base curve and material index of refraction.

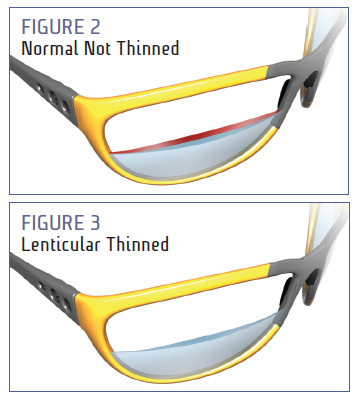

Lens thinning digital design technology (lenticularization) reduces the curvature and thickness in the periphery of the lens for better cosmetics, safety and comfort in high wrap frames (see Fig. 2 and Fig. 3). Design optimization of the lens surface design enhances optics from edge to edge, while wrap and prescription digital design compensation are employed to produce the same Rx power in the "as-worn" frame position as the prescribed prescription power.

State-of-the-art digital surfacing goes beyond spherical base curves utilizing 5-axis CNC lathes to apply digital lens designs with pinpoint accuracy, for thousands of points on the lens. Advanced digitally designed and surfaced lenses, whether single vision or progressive, provide increases and optimizes fields of view in all directions along with increased image stability, edge to edge distortion-free vision with no swim effect, and improves night vision by minimizing peripheral aberrations in the lens.

MIRROR COATING TECHNOLOGY EXPERTS AND PIONEERS

iCoat specializes in the development and licensed sale of thin-film deposit and coating technologies for premium optical equipment. They are known for their extensive research and development capabilities which have produced proprietary super-oleophobic, anti-reflective coating. Over the years they pioneered and established engineering standards for lens coatings. Their lens coating expertise follows an array of technologically advanced handling and treatment processes that result in highest quality lens treatments.

Mirror coatings can be solid or flash and are engineered using dielectric process technology under controlled vacuum conditions to deliver lenses that satisfy the increasing demand for greater sun protection, providing 100 percent UV400 protection and guarding against harmful high energy visible light. The latest technological advancements result in a durable, antistatic, slick and easy to clean premium quality sunwear. iCoat's mirror lenses come with backside AR with LUV (Low UV reflection) technology that helps reduce annoying backsurface reflections prevalent on dark lenses and provide ultimate protection against damaging back-surface UV reflections. Each pair of their mirror lenses offer high durability and scratch resistance and is guaranteed against cracking, peeling, crazing and scratching.

Solid and flash mirror densities: Solid mirror coatings have a higher percentage of luminous reflectance than their corresponding flash mirror colors. The flash mirror generally has a hint of the color whereas a solid mirror shows a higher density of the color. Mirror-coated lenses absorb anywhere from 5 to 65 percent more light than non-mirrored lenses, depending on the color and density of the coating.

Solid and flash mirror densities: Solid mirror coatings have a higher percentage of luminous reflectance than their corresponding flash mirror colors. The flash mirror generally has a hint of the color whereas a solid mirror shows a higher density of the color. Mirror-coated lenses absorb anywhere from 5 to 65 percent more light than non-mirrored lenses, depending on the color and density of the coating.

Mirrors are popular with sport enthusiasts, particularly those participating in activities such as golf, skiing, snowboarding, hunting, fishing and hiking. When combined with various tinting options and a polarized filter, they can provide great sun and glare protection.

- Perception of color to wearer may change when looking through a tinted mirror sunglass. Tint colors must not interfere with traffic signal color recognition.

Tint color considerations: Tint color samples and polarized demonstration tools are highly effective in helping the customer "see" the benefits. Guide their decision by advising them on the colors and lens treatments that are best for their particular activity. For everyday use outdoors in moderate to bright sunny conditions, dark tints and hues work best. The dark colors typically include brown, gray and green. Gray and green lenses maintain color neutrality while brown lenses are high contrast making greens, yellows and reds pop; on the downside, they will cause the sky to look less blue, dulling it with a brown cast. Choices for sun lenses being used in moderate to low-level light conditions include colors such as amber, rose and vermillion; lighter tints and hues are often preferred by those who participate in snow sports such as skiing or snowmobiling because they can enhance contrast in the presence of tricky, flat light conditions.

Yellow lenses are an excellent choice for hunters or shooters. They prefer yellow lenses that brighten their surroundings and sharpen contrast, making details and edges sharper against the background, resulting in higher definition vision.

A solid mirror coating will reduce more light transmission by reflecting more light from the front surface of the lens than a flash mirror coating. ANSI requires a minimum light transmission of 8 percent, and for this reason, a mirror coating is not recommended for tints with less than 20 percent visible light transmission (VLT).

STATE-OF-THE-ART AR COATINGS

We know the main advantages of AR coating are to improve optics when viewing the world through lenses and to make the lenses cosmetically appealing (no windshield effect reflections). iCoat Aura's AR has neutralized polarity to increase anti-static effectiveness to repel more dust, dirt and lint. The result is increased durability with less cleaning required. Ion-assisted deposition and proprietary chemical composition of the stack produce ultra-tough chemical layers that are virtually impervious to wear and tear in the currently available state-of-the-art AR coatings. Super oleophobic and hydrophobic topcoats seal the AR layers with a super slick polymer based topcoat that protects against smudges, fingerprints and moisture to promote easy cleaning of the lens. Backside UV AR coating minimizes harmful UVB and UVA reflections from the back surface of the lens into the eye. Blue filter AR coatings on clear lenses help reduce digital eyestrain.

STATE-OF-THE-ART ANTI-FOG COATINGS

Anti-fog coating is recommended for ophthalmic lenses, safety goggles, face shields, sport eyewear and industrial applications. Premium anti-fog coating reduces water droplet surface tension so that they disperse into a continuous thin sheet that provides clear fog-free vision.

Anti-fog coating is recommended for ophthalmic lenses, safety goggles, face shields, sport eyewear and industrial applications. Premium anti-fog coating reduces water droplet surface tension so that they disperse into a continuous thin sheet that provides clear fog-free vision.

With their state-of-the-art technology, iCoat anti-fog coatings can be applied to any lens style in a large variety of materials including plastic, polycarbonate, Trivex, acrylic hi-index and mid-index materials as well as glass substrates. Anti-fog can be applied to lenses with AR, mirrors and scratch resistant coatings.

STATE-OF-THE-ART EDGING AND FINISHING

iCoat has perfected the craft of making high-performance eyewear through years of research and continuous investment in technology. For the crucial finishing stage of manufacturing high-performance eyewear, they utilize a multitool freeform edging system that is fully automated, fast, flexible and accurate. This freeform edger cuts the lens surface with a 5-axis computer numeric controlled (CNC) generator which accommodates the most complex and challenging jobs, even partially shelved lenses for fashion sport frames. This machinery allows for the most intricate lens edge processing (with base curves from 0 to 16 diopters) from various edging angles, with the highest degree of accuracy. Six-spindle edging produces complex bevels (step and shelf), notches, grooves and drilled (lateral) lenses, even for challenging lens shapes and wrap designs. The smart bevel function automatically places the bevel according to frame base and lens thickness.

SERVICE IS KEY

iCoat believes service is the key element of a quality lab from customer service to turnaround time, to educating the ECP and staff. They are able to facilitate what they consider the fastest turnaround time in the industry by performing every aspect of high-performance eyewear production in-house, from digital surfacing to coating to 5-axis edgers capable of producing complex bevels and notches.

Our industry is a technology-driven market, with the continuous introduction of products and advancements in technology. Work with labs that are committed to providing the training and information you need to stay abreast of current development. iCoat provides Continuing Education (CE) programs, ABO-approved educational seminars, and other webinars and presentations, and programs designed to help develop staff confidence and competence, as well as improve sales techniques, product knowledge and professional growth.

Not all of us require high-performance sport and safety eyewear, but all of us can benefit when the same precision, protection and optical-enhancing features used to make high-performance eyewear are applied in the production of our dress eyeglasses and sunglasses.

Not all of us require high-performance sport and safety eyewear, but all of us can benefit when the same precision, protection and optical-enhancing features used to make high-performance eyewear are applied in the production of our dress eyeglasses and sunglasses.

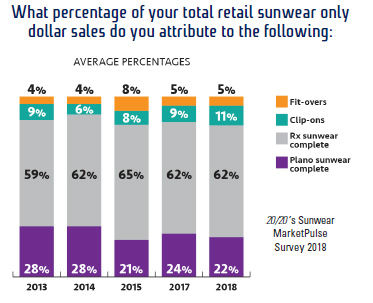

Sunwear is a huge potential growth segment in the optical market according to 20/20's 2018 Sunwear MarketPulse Survey conducted by Jobson Optical Research. Of the 200-plus independent ECPs surveyed in 2018 on how sunwear sales are performing, 70 percent of respondents said that Rx sunwear is growing for their practice. Sixty-three percent said consumers are more knowledgeable about sunwear than they were five years ago. On average, respondents said 62 percent of total retail sunwear sales comes from Rx complete, 22 percent from plano complete, 11 percent from clip-ons and 5 percent from fit-overs. When asked what the greatest differentiating quality independents have over other channels was, superior service takes the top spot with 33 percent, followed by product customization at 31 percent and frames/lens knowledge at 25 percent. July/August were rated the highest sunglass sales months for 67 percent of independents.

Grow your high-performance sun and sport eyewear sales with the help of the experts. Whether it's a high-definition compensated digital lens or a premium lens with mirror coating, or a stock lens with premium AR or a high power complex Rx surfaced and edged into a high-wrap sport-frame, you'll sleep better knowing that your customer's lenses and eyewear are being made with the highest performance level and with unparalleled precision.