Electronic Order Management: Elevating the Art of Spectacle Making

Optical Technology Product Spotlight: ZEISS VISUSTORE

By Barry Santini, ABOM

Release Date: July 1, 2022

Expiration Date: June 16, 2023

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Learn how changes in frame fashion inspired the creation of both and Boxing systems of frame markup and lens layout in the lab.

- Understand how using a state-of-the-art electronic ordering portal is a far more sophisticated and appropriate way to create, evaluate, process, and manage spectacle orders

- Learn how spectacle lens ordering and making has changed to accommodate changes in both frame and lens design

- Recognize that working with lens premium freeform lens manufacturers who offer a state-of -the -art digital online lens ordering systems reduces stress for the ECP by being easier, faster, and more accurate.

Faculty/Editorial Board

Barry Santini graduated from New York Technical College in 1975 with an AAS in Ophthalmic Dispensing. He is a New York State licensed optician with contact lens certification, is ABO certified and was awarded an ABO Master in 1994. As sales manager for Tele Vue Optics from 1987 to 2003, Santini developed his knowledge of precision optics and has been an owner of Long Island Opticians in Seaford N.Y. from 1996 to present. In addition, Santini is an amateur astronomer and lecturer and plays bass trombone in the Brooklyn Symphony.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO) for Technical Ophthalmic Level 2.

Course # STWJH018-2

Over the last century, both frame and lens technologies have seen exponential growth, bringing us advanced customized digital designs and precision surfacing on the fly. Yet, despite these advances in lens manufacturing, the way we order lenses has hardly changed. Optical businesses now have the full capabilities of the latest electronic lens ordering portals (ELOP) to optimize all aspects of spectacle lens ordering and tracking for efficient workflow.

We have all become accustomed to living life in the age of digital devices that frankly make our lives easier. We now easily, quickly and efficiently conduct personal and work-related business and tasks online, from grocery shopping to appointment scheduling, virtual medical visits, health and fitness monitoring, and so much more, all of which improved our lives. It is time to embrace new ELOP technology to improve opticians’ lives while ensuring easy, fast, accurate and intelligent lens ordering and tracking. In this course, you will learn the history of lens ordering and the synergistic relationship between the frame shape, the fit and the centration of the lenses. You will also be introduced to a state-of-the-art ELOP tool, the ZEISS VISUSTORE online lens ordering system.

MODERNIZATION OF SPECTACLE

ORDERING AND TRACKING

MODERNIZATION OF SPECTACLE

ORDERING AND TRACKING

For most of spectacle-making history, glasses were peddled from a street vendor’s cart—not measured nor fitted—but instead purchased already assembled as a complete vision aid. Eyeglass “consumers” sampled a variety of units until one complimented the wearer’s vision. This is not very far removed from how over-the-counter readers are sold even today. But would any eyecare professional suggest such a dated and unsophisticated method to select custom prescription eyewear? I think not. Yet many optical offices remain content with placing their eyeglass and lens orders using only basic Rx and frame information via fax or phone. And even though electronic lens ordering portals—or ELOPs—are readily available and have matured in the last 20 years, many ELOPs lack the full sophistication and user-friendliness

needed for getting the most from today’s advanced freeform lens designs. In addition, the ever-increasing demands of consumers and business competition are dictating the need for a more comprehensive communications approach to order status—one that is far less reliant on a daily exchange of phone calls to discover individual job status, shipping or tracking information.

To fully appreciate what today’s best electronic ordering portals can do to help ECPs make the best pair of glasses possible, let’s look back at the history of frames, lenses and the art of spectacle making.

THE EARLY ART OF MAKING GLASSES

Starting in the early 14th century with the founding of the Guild of Venetian Spectacle Makers, the art of making glasses was kept very secretive, along with all the hard-won knowledge of glass making that originated in the regions of Venice and Murano, dating back to the time of the Roman Empire. However, as far back as the 8th century, Venice had already become known as the center for the art of glass making.

The art and science of lens and frame making have grown tremendously since humble origins. Mass production came to the craft of making glasses in the early 20th century. In 1912, ZEISS launched the Punktal, and “first quality” lenses were introduced. In the 1920s, other ophthalmic lenses makers, such as Bausch and Lomb, American Optical and Shuron, began to focus their mass production efforts to produce first quality lenses—meaning they were certified to be water white in color and free of all defects, including blemishes, waves and inclusions.

FRAME FITTING

From 1920 to approximately 1940, frame styling was mainly comprised of round, oval, hexagon and other symmetrical shapes. The 1930s were the time of primarily metal and rimless frames. Choosing the correct frame size was accomplished using the datum system, guided by the following workflow:

1. Determination of the correct bridge fit/size.

2. Using the (binocular) PD, a target lens size was chosen, guided by the desire to avoid any decentering of the lenses in the finished glasses. Sometimes decentering was unavoidable because of constraints imposed by the need to fit the facial width of the wearer. But even this deviation was studiously avoided in the higher-powered prescriptions.

3. The optical center default position was set vertically at the “180,” the point in line with the midpoint of the frame shape. With frame sizes and styling kept small, mainly because the lens blanks manufactured at the time were also small in diameter, the frame front was nominally fitted with zero pantoscopic tilt. The OCs were mounted right in front of the pupil—a perfect optical fit even by today’s more sophisticated standards.

This datum fitting system, created by the Cole and Blackburn UK firm in 1935, was perfect for these genderless and symmetrical frame styles. Therefore, the layout and ordering of glasses were quite simplified since using the datum system to label bridge and lens size strongly correlated with how glasses were measured and fitted. But the datum fitting system was about to undergo a great challenge, driven primarily by the desire for new and novel frame shapes.

FRAME FASHION CREATES NEW HURDLES

As the 1940s unfolded, artists like Altina Schinasi, the arguable inventor of the upswept “harlequin” frame style, started experimenting with frames of unusual and unsymmetrical lens shapes inspired by the harlequin carnival masks of Venice. Around this time, the optical visionary Monroe Levoy, founder of the frame company Tura, directed their business efforts specifically toward styling women with the latest feminine eyewear fashion. While fitting these CatEye frame shapes, the frame center was no longer centered routinely on the pupil. In these new shapes, the lens’ temporal point was higher and wider than the nominal pupil position and facial width.

As the 1950s dawned, optical labs found themselves challenged when determining the smallest—and therefore the cheapest—glass lens blank that would layout to accommodate the wearer’s pupillary distance. If a finished offthe-shelf lens of the correct diameter were not available, it would likely have been custom made by the lab, further increasing the eyewear’s cost. Knowledge of the minimum blank size needed for a spectacle order kept costs down and helped ensure the glasses were as light as possible, particularly in plus-powered prescriptions. In this heyday of glass lenses, cost and weight were everything since most of the public did not want to wear glasses, let alone expensive and heavy ones.

At Winchester Optical Laboratory in Elmira, N.Y., owner Tom Lynch started publishing a Lens and Frame Information book that featured a Winchester employee’s suggested idea of “boxing” unsymmetrical lens shapes to best determine the smallest blank size needed in filling an order for glasses. The Winchester book of frame and lens information evolved into our current boxing system of frame measurements. This new frame marking method became standard in 1961 after being codified by the American Optical Manufacturer’s Association—the predecessor organization to OMA and today’s Vision Council.

ORDER PROCESSING EVOLVES

Since the 1960s, the only significant development in the way glasses was ordered and made occurred with the introduction of frame tracing technology, which digitized a specific frame’s shape. It was easier to determine the final prescription lens thickness and blank size required, armed with this far more precise shape information. Digital frame tracing was especially important since a critical piece of frame information was routinely left out in most lens orders using the boxing system: the axis—or direction—of the radius that determines the lens shape’s effective diameter (ED). With digitized frame tracing, the axis of the lens’ ED is always present. As lab management systems (LMS) further evolved and became streamlined, spectacle making was transformed from a centuries-old handmade craft to a finely tuned manufacturing endeavor.

The ordering and making of glasses finally became as precise as the optics in the finest lenses available.

THE PATH TO THE FINEST LENSES

During the first 600 years or so after its invention in 1275, making spectacle lenses was an empirical science—that is, a lens design was created using a trial-and-error approach primarily with one’s senses used to determine “what worked.” It wasn’t until late in the 19th Century that mathematics was first applied to improve lens performance. Names like Gullstrand, Tscherning and Ostwalt used scientific calculations to build upon the empirical foundation of improved sharpness created by early lens researchers such as Wollaston and Petzval. By the second decade of the 20th century, Dr. Moritz von Rohr of Carl Zeiss had created a lens that would become the pinnacle of the single vision lens design for the next 50 years: the ZEISS Punktal. Although further production-friendly refinements were made by corrective curve design designers such as B&L’s Rayton and AO’s Tillyer, ophthalmic lens design, using spherical rear curves, matured into a stable and somewhat unchanging industry. It wasn’t until the early 2000s when ZEISS patented freeform progressive lenses whose front surfaces are rotationally symmetric with the back-surface design determined by the individual prescriptions alone or combined with other customization options, that spectacle lens design significantly advanced beyond the science of the Punktal lens.

ENTER ELECTRONIC LENS ORDERING

As the optical industry entered the new millennium, free form manufacturing and digitally optimized lens design came into stride. Progressive lenses became ever more user friendly, with improved reading utility and far less overall optical compromise because of the presence of the progressive umbilic. With the ability to custom enter position of wear measurements, more and more progressive wearers could enter the realm of 20/Happy. Despite 60 years since its arrival, the simple boxing system of A, B and DBL frame measurements remained the foundation many eyecare professionals use for all their spectacle orders. With the advent of electronic lens ordering in the new millennium, eyecare professionals finally had the opportunity to advance the spectacle ordering process into the 21st century.

EARLY ORDERING PORTALS

Internet speed finally became fast enough in the early 2000s, to allow duplex communication in lens ordering, where hierarchal choices are communicated to a server, which then serves up a tailored “next-up” list of options based upon the selections already made. The challenge for portals here is keeping the catalog of available product choices current. As new products constantly enter the market, they are added to the portal, creating the challenge of scrolling through an endless list of choices. This situation is ripe to create operator fatigue and order-entry errors. Further, early lens ordering portals often required an engineering degree to connect a tracer for uploading a job’s frame tracing. Let’s imagine what an ideal contemporary ordering portal might look like if we could overcome these challenges.

THE IDEAL ORDERING PORTAL

What might it contain if we wrote a list of wishes for the perfect order management system?

1. User-friendly interface—one capable of handling orders from finished stock lenses to the most sophisticated and advanced freeform and personalized progressives.

2. Practice personalization—Portal access is restricted to qualified staffers, with recordkeeping that tracks the orders an individual staffer placed.

3. Quick and easy tracer configuration— connecting a tracer to upload frame tracings should be as close to a plug-and-play affair as possible.

4. 3D visualization—after entry of the order, a way of reviewing what the finished lens would look like before the order is placed. 5. Human-factor friendliness—Let’s face it: People make mistakes because they’re human. A contemporary order management system should help reduce those mistakes instead of facilitating them to become a stack of lab callbacks or unwanted redos.

6. Order history, status and delivery tracking— the ability to quickly call up previous order history is essential when a job is delayed because a redo is required. In addition, an important part of contemporary customer service is the ability to provide accurate projections of when a pair of glasses will be ready for delivery—without the need to phone the lab and wait for a callback.

7. Ongoing portal improvement—nothing is more of a downer than having mutually agreed upon changes delayed in implementation to an ordering platform. Improvements should arrive as a surprise, rather than feeling “it’s about time.”

ENTER ZEISS VISUSTORE

ENTER ZEISS VISUSTORE

VISUSTORE is ZEISS’ comprehensive answer to the contemporary order management challenges facing every main street optical. Let’s review VISUSTORE’s highlights: 1. Order accuracy—VISUSTORE has native intelligence built into its back end so that the latest lens and treatment choices are immediately available to order. A big bonus with VISUSTORE is it’s impossible to place an order with incompatible elements or create an order that cannot be made.

2. Lens family filtering—VISUSTORE supplies a filter-tree option, which lets the operator narrow the lens and treatment selection process by checking off material, design, color, photochromic or blue filter properties, etc. As one checks off the appropriate boxes, a side panel opens and shows all the filtered choices that meet the selection criterion, eliminating the endless scrolling through unwanted choices.

3. Efficiency—Unlike other portals, your order entry in VISUSTORE is communicated directly into the ZEISS LMS, so there are no delays because of a need for file conversion.

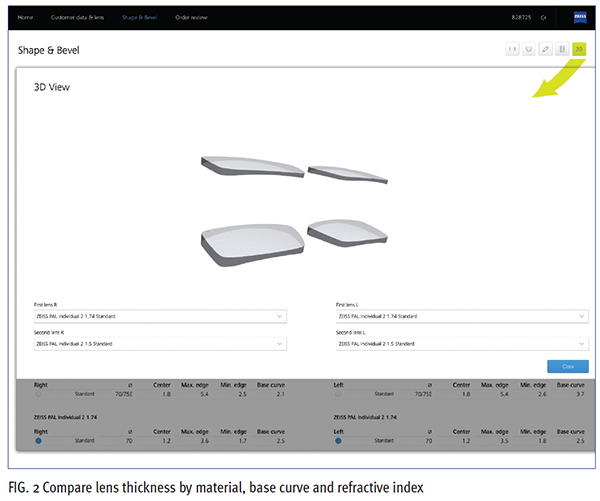

4. Visualization—After communicating with the ZEISS server, VISUSTORE offers several unique and helpful visualization tools:

• “Actual size” lens representation, including the ability to accurately calibrate the operator’s display.

• 3D visualization includes rotating the lens rendering and observing the fin ished pair of lenses from different angles.

• Thickness comparison—3D rendering of two pairs of lenses illustrates lens thickness comparison by material, base curve or refractive index.

• Advanced corridor simulation—Using information after the lens has been cal culated, VISUSTORE can determine and show the location of the near power. The user can then select a different lens if they want a shorter or longer corridor value allowing VISUSTORE to instant ly reveal a graphic illustration of where a specific progressive lens’ default, the 100 percent of the add power reading point, will fall. The operator can then change this Frame Fit value, which effectively changes the corridor value while still staying within the chosen progressive design’s unique fingerprint.

• Base curve selection—One of VISUS TORE’s best features is its ability to select a base curve and see if that choice is avail able for the specific lens design and mate rial index chosen. If not, the VISUS TORE Calc Engine will supply the next closest value acceptable to the LMS. If you’re supplying uploaded tracings, VISUSTORE’s default base curve will be the closest to the frame’s eye wire curve.

5. Connectivity—VISUSTORE connects with your account’s ZEISS Dashboard to review up-to-date order status and shipment tracking information.

6. Easy tracer configuration—plug and play tracer setup.

7. Practice personalization—individual employee setup and searchable records including stock lens orders, along with order-specific value configuration including:

• Plus/minus cylinder convention.

• Edge polish.

• Preference setting for input, including diopter precision, default right/left input value duplication and even the ability to review both polar and X-Y prism notation simultaneously.

• VISUSTORE interfaces with most practice management systems.

8. Commitment to ongoing development— ZEISS is committed to the ongoing development of VISUSTORE and places high value on all user input toward improvement.

9. Special bonus features—There are many hidden nuggets in VISUSTORE. One of my favorites is for accounts such as myself who primarily do uncut lenses. VISUSTORE displays the appropriately modified blocking values for PD and height in a progressive order with a prism. Many often overlook this area, but it ensures the progressive corridor is optimally aligned when prescribed prism is present.

ENTER THE 21ST CENTURY OF SPECTACLE ORDERING

In an age of advanced freeform lenses, the personalized position of wear measurements and opticians who relish designing their client’s glasses as much as they style them, an advanced ordering portal like VISUSTORE is sure to be a welcome addition to any practice. While online companies using big data are promoting averages as good enough to get almost any buyer to 20/Happy, companies such as ZEISS continue to go beyond just good enough and are committed to delivering the highest levels of optical excellence. If you also view yourself as committed to delivering your patients the full value of every dollar they spend, then you owe it to yourself to leave behind phone and fax, and use just the basics of the boxing system and enter the 21st century with ZEISS’ powerful VISUSTORE.