PRODUCT SPOTLIGHT - SUNSENSORS™ AND CRYSTALCHROME™

BREAKING BONDS – MAKING PHOTOCHROMIC LENSES LIGHT RESPONSIVE

By Deborah Kotob, ABOM

Learning Objectives

Upon completion of this course you should understand:

- Learn about photochromic lens improvements in both dip coat and in-mass technologies.

- Learn about how photochromic material choices, as well as casting and coating options, have expanded with new Mitsui Chemicals photochromic developments.

- Learn the essentials for communicating the patient benefits of photochromic lens convenience and comfort.

Course Description

This course describes the latest advances in two kinds of photochromic technology from Mitsui Chemicals. One is a casting technology for in-mass, and the other is the new patented CrystalChrome™ thermal cured dip coat photochromic technology. This course will help you better understand the CrystalChrome dip coat and the expanded MR™ series materials that SunSensors™ in-mass technology makes possible. Better technology means better products, better material choices and satisfied customers. It is a Win-Win for the patient and the practice!

Faculty/Editorial Board

Deborah Kotob, ABOM is currently director of education for Jobson Medical Information LLC, has more

than 20 years of experience as an optician. With over 10 years in lens manufacturing as a Sales

Consultant, Trainer and LMS content developer. She lectures, trains, and conducts webinars on a variety

of optical and practice development topics.

Deborah Kotob, ABOM is currently director of education for Jobson Medical Information LLC, has more

than 20 years of experience as an optician. With over 10 years in lens manufacturing as a Sales

Consultant, Trainer and LMS content developer. She lectures, trains, and conducts webinars on a variety

of optical and practice development topics.

Credit Statement

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Course number: STWJHI038-2 Ophthalmic Level II Course

THIS COURSE IS SUPPORTED BY AN EDUCATIONAL GRANT FROM MITSUI CHEMICALS, INC.

Manufacturers are always searching for ways to

improve the patients’ visual experience. To do so means

pushing the limits of technology to discover newer

and better chemistry to produce the best material and

coating solutions for lenses, including photochromic lens technology. Each

photochromic technological advancement is born

from either a material or

coating solution improvement. This course describes

the latest advances in two

kinds of photochromic

technology from Mitsui Chemicals. One is a casting

technology for in-mass, and the other is the new patented CrystalChrome™ thermal cured dip coat photochromic technology. This course will help you better

understand the CrystalChrome dip coat and the

expanded MR™ series materials that SunSensors™ in-mass technology makes possible. Better technology

means better products, better material choices and satisfied customers. It is a Win-Win for the patient and

the practice!

Manufacturers are always searching for ways to

improve the patients’ visual experience. To do so means

pushing the limits of technology to discover newer

and better chemistry to produce the best material and

coating solutions for lenses, including photochromic lens technology. Each

photochromic technological advancement is born

from either a material or

coating solution improvement. This course describes

the latest advances in two

kinds of photochromic

technology from Mitsui Chemicals. One is a casting

technology for in-mass, and the other is the new patented CrystalChrome™ thermal cured dip coat photochromic technology. This course will help you better

understand the CrystalChrome dip coat and the

expanded MR™ series materials that SunSensors™ in-mass technology makes possible. Better technology

means better products, better material choices and satisfied customers. It is a Win-Win for the patient and

the practice!

Why Photochromic? Best value with two-pairs in-one convenience! It’s an eyeglass; it’s a pair of sunglasses, it’s both! Photochromic lenses provide convenient, comfortable vision in a lens that alleviates discomfort glare outdoors while providing a reduction in visible light transmission, including outdoor blue light and 100 percent UV protection, in one pair.

Let’s hear from master optician Mark Mattison

Shupnick, ABOM, on why he loves the freedom of

owning photochromic lenses: “As a wearer of photochromic lenses, I think the convenience and comfort of photochromic lenses

provide the most value in

any eyeglasses because

they adapt to light conditions, changing color density in the presence of UV

and back to clear upon its

removal. As a person

lucky enough to have

multiple pairs of glasses, I often think about the day’s activities. Will I carry a

backpack to hold an extra pair of sunglasses, or will the

convenience of my photochromic lenses be all that I

need for the day? I believe this is an opportunity that

all consumers deserve. It doesn’t remove the reason

that all should have a pair of polarized sunglasses, especially when driving or spending extended periods outdoors in bright or high-glare conditions. However, it

does suggest that as long as only one pair of glasses stays

the norm, that eyewear should be photochromic.”

Let’s hear from master optician Mark Mattison

Shupnick, ABOM, on why he loves the freedom of

owning photochromic lenses: “As a wearer of photochromic lenses, I think the convenience and comfort of photochromic lenses

provide the most value in

any eyeglasses because

they adapt to light conditions, changing color density in the presence of UV

and back to clear upon its

removal. As a person

lucky enough to have

multiple pairs of glasses, I often think about the day’s activities. Will I carry a

backpack to hold an extra pair of sunglasses, or will the

convenience of my photochromic lenses be all that I

need for the day? I believe this is an opportunity that

all consumers deserve. It doesn’t remove the reason

that all should have a pair of polarized sunglasses, especially when driving or spending extended periods outdoors in bright or high-glare conditions. However, it

does suggest that as long as only one pair of glasses stays

the norm, that eyewear should be photochromic.”

Convenient outdoor visual comfort: Why do

most of us wear sunglasses? Discomfort glare!

Think about kids—they find it difficult to manage more than one pair of eyewear. Yet, they are

the most vulnerable to sun damage to their young

developing eyes. A 2016 VisionWatch survey

from The Vision Council of over 10,000 adults

over age 18 found that only 31 percent of survey

respondents reported wearing sunglasses all the

time outdoors. And only 7.4 percent say that their

children always wear sunglasses outdoors! Now

imagine if everyone had photochromic lenses for

all the time spent outdoors without sunglasses.

Convenient outdoor visual comfort: Why do

most of us wear sunglasses? Discomfort glare!

Think about kids—they find it difficult to manage more than one pair of eyewear. Yet, they are

the most vulnerable to sun damage to their young

developing eyes. A 2016 VisionWatch survey

from The Vision Council of over 10,000 adults

over age 18 found that only 31 percent of survey

respondents reported wearing sunglasses all the

time outdoors. And only 7.4 percent say that their

children always wear sunglasses outdoors! Now

imagine if everyone had photochromic lenses for

all the time spent outdoors without sunglasses.

Convenient light radiation protection: SunSensors and CrystalChrome Photochromic lenses have protection from harmful HEV blue light and ultraviolet radiation built Into the Lens. High energy visible (HEV) blue light exposure from the sun is linked to retinal damage. HEV blue light penetrates the inner eye, reaching the lightsensitive retinal layer at the back of the eye. HEV light is short-wavelength, high-energy blue light with enough energy to cause oxidative stress in the retina and damage cells. Damage to cells of the macula at the center of the retina from excess blue light exposure has been linked to an increased risk of age-related macular degeneration (AMD). SunSensors photochromic lenses block a high level of these harmful rays when in an activated (darkened) state. As reported on the Macular Degeneration Association site in an article titled “Ultraviolet and Blue light” written by Dr. Ronald Melton, “The average proportion of blue light that’s found in sunlight during the day is between 25 percent to 30 percent.” Sunglass lenses, by their nature, reduce visible light transmission across all visible wavelengths to an average of 15 to 25 percent transmission. SunSensors gray lenses transmit only 14 percent of visible light transmittance (VLT), and SunSensors brown lenses transmit only 12 percent VLT when fully activated, thereby dramatically reducing all wavelengths of VLT, including blue.

If money were no object, patients would want

every lens enhancement. And they would want

only the best materials used in their eyewear.

Today’s informed consumer weighs the value of

the lens options. Therefore, each benefit must be

made clear. Consequently, the ECP must know

the newest technological advancements in photochromic. How have they improved upon old

technology? We must clearly explain the benefits to the patient in simple terms, always tying it

back to how it will make their lives better. So

what’s the value to the patient when upgrading

their general-purpose everyday pair of eyewear

to photochromic? They never leave home without protection from harmful sunlight or discomfort glare. Forgot your sunglasses? It’s not a

problem; your lenses automatically change to

sun lenses in sunlight. But do they become clear

when indoors? Yes, this latest photochromic

technology fades back to clear very fast indoors.

The protection value of these lenses cannot be

overstated; the following is a list of the parts of

the eye potentially damaged by UV radiation.

If money were no object, patients would want

every lens enhancement. And they would want

only the best materials used in their eyewear.

Today’s informed consumer weighs the value of

the lens options. Therefore, each benefit must be

made clear. Consequently, the ECP must know

the newest technological advancements in photochromic. How have they improved upon old

technology? We must clearly explain the benefits to the patient in simple terms, always tying it

back to how it will make their lives better. So

what’s the value to the patient when upgrading

their general-purpose everyday pair of eyewear

to photochromic? They never leave home without protection from harmful sunlight or discomfort glare. Forgot your sunglasses? It’s not a

problem; your lenses automatically change to

sun lenses in sunlight. But do they become clear

when indoors? Yes, this latest photochromic

technology fades back to clear very fast indoors.

The protection value of these lenses cannot be

overstated; the following is a list of the parts of

the eye potentially damaged by UV radiation.

According to Prevent Blindness, ultraviolet

radiation exposure is linked to ocular disorders

such as cataracts—when the Crystalline Lens is

exposed to UV rays, especially UV-B rays, a cataract can form, clouding the eye’s natural lens. The

lens is an essential part of the eye that focuses light

on the retina for sharp vision. A clouded lens produces a blurred image. Corneal sunburn, called

photokeratitis, results from the high exposure of

the cornea to UV-B rays. For example, long hours

at the beach or skiing without proper eye protection can result in photokeratitis. It can be very

painful and may cause temporary vision loss.

Pterygium is another UV-related problem for

the cornea. It is a wedge-shaped growth that

begins on the white of the eye but can grow into

the cornea, obstructing vision. It is more common

in people who work outside in the sun and in the

wind. Macular degeneration is linked to UV

radiation exposure to the retina. Macular degeneration is the leading cause of vision loss for older

Americans. Skin cancer on and around the delicate skin of our eyelids is linked to UV exposure.

According to Prevent Blindness, ultraviolet

radiation exposure is linked to ocular disorders

such as cataracts—when the Crystalline Lens is

exposed to UV rays, especially UV-B rays, a cataract can form, clouding the eye’s natural lens. The

lens is an essential part of the eye that focuses light

on the retina for sharp vision. A clouded lens produces a blurred image. Corneal sunburn, called

photokeratitis, results from the high exposure of

the cornea to UV-B rays. For example, long hours

at the beach or skiing without proper eye protection can result in photokeratitis. It can be very

painful and may cause temporary vision loss.

Pterygium is another UV-related problem for

the cornea. It is a wedge-shaped growth that

begins on the white of the eye but can grow into

the cornea, obstructing vision. It is more common

in people who work outside in the sun and in the

wind. Macular degeneration is linked to UV

radiation exposure to the retina. Macular degeneration is the leading cause of vision loss for older

Americans. Skin cancer on and around the delicate skin of our eyelids is linked to UV exposure.

The UV hazard exists even on cloudy days:

Ultraviolet radiation is an invisible threat to our

eyes, just as it poses a danger to the skin. UV light

is invisible but always present in the daytime,

regardless of the time of year, even when the sun is

behind the clouds.

The UV hazard exists even on cloudy days:

Ultraviolet radiation is an invisible threat to our

eyes, just as it poses a danger to the skin. UV light

is invisible but always present in the daytime,

regardless of the time of year, even when the sun is

behind the clouds.

According to the World Health Organization (WHO), “Constriction of the pupil, closure of the eyelids and the squinting reflex minimize the penetration of the sun’s rays into the eye. These mechanisms are activated by bright visible light and not by UV radiation—but on a cloudy day, UV radiation exposure may still be high. Therefore, the effectiveness of these natural defenses in protecting against UV damage is limited.”

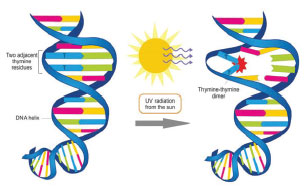

UV HAZARD: BREAKS BONDS AND DAMAGES DNA

Ultraviolet light (UV) is non-ionizing radiation that can damage DNA; the accumulation of DNA damage kills cells. UV radiation contributes nothing to sight but can cause irreversible damage to ocular tissue, including retinal cells. Over time, cataracts and other eye maladies develop from UV damage. Benjamin Franklin once stated, “An ounce of prevention is worth a pound of cure.”

TWO PHOTOCHROMIC TECHNOLOGIES

Mitsui Chemicals has advanced photochromic solutions with two technologies. CrystalChrome Photochromic Suite is the thermal cured dip coat solution, and SunSensors in-mass is the photochromic solution that expands photochromic availability in high index 1.60 MR-8™.

BREAKING BONDS MAKING

LENSES LIGHT RESPONSIVE

BREAKING BONDS MAKING

LENSES LIGHT RESPONSIVE

• A chemical bond is broken in the dye molecule when exposed to UV radiation.

• The dye molecule rearranges into a chemical structure that absorbs light in the visible spectrum causing the lens to darken.

• No UV = closed dye molecules = clear (deactivated) state

• UV Present = open dye molecules = darkens (activated) state

SunSensors Ultra-Dye Dispersion: The newest premium in-mass light-reactive lens technology expands the high index material options 1.60 index MR-8 for photochromic lenses. Ultra-Dye Dispersion technology enables the even dispersion of dye molecules throughout the lens monomer. The availability of premium photochromic technology in the optician preferred high index materials is a win for the ECP and the patients. Roughly 6 of every 10 pairs of glasses sold in the U.S. today are of thinner, lighter, more impact resistant lenses and 100 percent UV absorptive. When asked why opticians choose “high premium Index,” they suggest that the higher refractive index makes for thinner, better-looking lenses, a higher Abbe number and surface finish ensures clarity. In addition, the high impact and reduced notch sensitivity or tensile strength make them perfect for rimless and drill. High index lenses have evolved to be the lens material of choice for premium eyewear. When combined with state-ofthe-art photochromic technology, the patient’s visual comfort and satisfaction are ensured.

Photochromic lenses for many patients are expensive, so durability is one key criterion of customer satisfaction. Product durability is an essential measure of value for the patient. Most opticians and photochromic consumers agree that even outdated photochromic lenses darken fast outdoors. But how fast do they return to clear? Thanks to SunSensor photochromic technology, fade-back speed is no longer an issue. SunSensors fast fade-back overcomes the primary objection that old technologies took too long to return to clear indoors. Both fade-back speeds and photochromic fatigue are no longer an issue. As ECPs, we must be aware of the technological improvements and confidently recommend them as the best comfort, convenience and protection built into the patient’s primary pair of eyewear.

SUNSENSORS: A HISTORICAL PERSPECTIVE

• 1964 Corning photochromic glass: Commercial availability of photochromic lenses had its origins in 1964 when Corning released glass lenses with variable tint technology, i.e., lenses changed color and density when exposed to ultraviolet light.

• 1999 Corning introduces SunSensors brand photochromic in plastic. In 1999, Corning applied its expertise to plastic lens materials introducing the SunSensors brand. Other companies further developed the technology and grew the photochromic market to where it is today, and this modern photochromic technology is available from a variety of manufacturing suppliers.

• 2014 Mitsui Chemicals, Inc.: In 2014, Mitsui Chemicals acquired the plastic photochromic materials business from Corning. As a major lens material supplier, they initiated the development of an improved photochromic that could take advantage of the other lens material benefits that it already supplied to the market.

• 2016 SunSensors 50HPM and SunSensors MR-8 became available: During 2016, Mitsui Chemicals began to test new SunSensors 50HPM, 1.50 index material and SunSensors MR-8 1.60 index material with its lens-casting customers.

CRYSTALCHROME SDC PHOTOCHROMIC COATING SYSTEM

Mitsui’s newest thermal dip cured CrystalChrome Photochromic Coating was introduced

in 2019. It is a best-in-class thermal cured dip coat

ophthalmic photochromic technology. Expanding photochromic solutions: SDC Technologies’

(a wholly-owned subsidiary of Mitsui Chemicals,

Inc.) CrystalChrome is the newest high-tech photochromic coating solution. The proprietary hard

coating suite offers best-in-class photochromic

performance for all lens substrates. It features fast

activation and fade-back speed along with durability and an extended lifespan of photochromic

performance without lens fatigue. It comes with:

abrasion resistance, chemical resistance and exceptional optical clarity. CrystalChrome technology

employs a dip coat and thermal cure process, compatible with anti-reflective and metalizing coatings with availability in all substrates: Plastic, PC,

MR-8 (1.60 indexes), MR-7™/MR-10™ (1.67

indexes), MR-174™ and Trivex. Enhanced durability and stability in CrystalChrome contribute

to its best-in-class photochromic performance,

including fast deactivation speed (dark to light).

Mitsui’s newest thermal dip cured CrystalChrome Photochromic Coating was introduced

in 2019. It is a best-in-class thermal cured dip coat

ophthalmic photochromic technology. Expanding photochromic solutions: SDC Technologies’

(a wholly-owned subsidiary of Mitsui Chemicals,

Inc.) CrystalChrome is the newest high-tech photochromic coating solution. The proprietary hard

coating suite offers best-in-class photochromic

performance for all lens substrates. It features fast

activation and fade-back speed along with durability and an extended lifespan of photochromic

performance without lens fatigue. It comes with:

abrasion resistance, chemical resistance and exceptional optical clarity. CrystalChrome technology

employs a dip coat and thermal cure process, compatible with anti-reflective and metalizing coatings with availability in all substrates: Plastic, PC,

MR-8 (1.60 indexes), MR-7™/MR-10™ (1.67

indexes), MR-174™ and Trivex. Enhanced durability and stability in CrystalChrome contribute

to its best-in-class photochromic performance,

including fast deactivation speed (dark to light).

The tint availability is gray and brown. The product is manufactured under stringent ISO 9001:2008 quality standards, and its long service life reduces the frequency of tank change-outs. CrystalChrome streamlines manufacturing, enhancing yields and profitability. Casters have access to SDC’s global technical support team for your product validation and application requirements. CrystalChrome SDC coating can easily be integrated into the lens manufacturer/labs’ dipcoating operations, meeting photochromic production needs for all lens materials. CrystalChrome SDC coating requires no pre-mixing, and its long service life reduces the need for frequent tank change-outs. Lenses are currently available through SOMO.

Loyal photochromic customers appreciate the extended life of photochromic performance. A review of performance after accelerated weather tests shows little change to either the fade time or the clear state color. These are important for patients who keep their glasses longer than the usual repurchase cycle. For example, the U.S. repurchase cycle for the over 55-year-old is about 2.8 years, meaning this customer keeps their glasses as long or longer than average, and their lenses will retain a near new lens photochromic performance. The longevity of photochromic performance is an essential dimension of value, particularly for this segment of loyal photochromic patients.

In summary, improved photochromic performance, such as fast fade-back speed and their availability in premium high-index material options, generates new sales opportunities and brings back customers that opted out in the past. Improvements in photochromic performance help the optician or doctor overcome photochromic bias. Lack of customer satisfaction with old photochromic technology deterred many ECPs from recommending photochromic lenses, and in some cases, they even discouraged the patient from considering photochromic lenses. This same ECP can now confidently present the many benefits of these convenient and protective lenses. Of course, the easiest way to convey confidence in a product is to wear them. In dispensing, most of us have multiple pairs of eyewear and have access to the best products. Shouldn’t we be wearing the best if we are recommending the best? And yes, photochromic is the best solution for everyone’s primary pair of eyewear.

One last objection to overcome is, “…they don’t get dark in the car…?” While generally true of photochromic lenses, it is also true of clear lenses. Yet, you would not use this reasoning to deter the patient from purchasing clear lenses. The new photochromic technology overcomes old objections, and now we must overcome outdated bias. Do not deprive the patient of the many positive reasons to have their primary pair of eyewear with photochromic lenses, thereby ensuring sunlight protection for their eyes, while providing added comfort from discomfort glare outdoors when their sunglasses aren’t handy. On another note, if we have the patient’s best interest at heart, shouldn’t we always recommend a pair of polarized sunglasses for driving to avoid blinding reflected glare? We all need multiple pairs for different visual needs, but none of our other pairs of glasses offers more benefits in one pair than our glasses with photochromic lenses.

The 2016 VisionWatch reports that only 31 percent of respondents report wearing sunglasses all the time outdoors. And only 7.4 percent say that their children always wear sunglasses outdoors! Now imagine if everyone had photochromic lenses, for all the time spent outdoors without sunglasses (source: The Vision Council 2016 VisionWatch Survey of over 10,000 adults over age 18). The advantage of photochromic lenses far outweighs any unfounded bias that prevents us from recommending them to all patients. And as we’ve seen, almost yearly, there are new improvements in photochromic lens performance, which eliminate objections of the past.

Build your business on excellence! Deliver eyewear that enhances the patient’s visual experience, and they will become loyal followers who tell friends and family. Our industry is reliant on NEW. We sell a product in which the wearer relies on the benefits of better vision. However, vision is just one aspect of a pair of glasses. While the usual driver to seek new eyewear is the opportunity to buy beautiful frames, patients will also appreciate thinner, lighter and more cosmetically appealing lenses that conveniently become sunglasses outdoors. The added benefits of convenience, comfort and protection available in new and improved SunSensors and CrystalChrome photochromic lens technologies will win them over. Offer the best in comfort, convenience and protection to every patient, and you will be rewarded. Deliver eyewear that enhances the patient’s visual experience, and they will become loyal followers who tell friends and family!

MR, UV+420cut, SunSensors, NeoContrast, UrbanPola, Do Green and RAV 7 are trademarks/registered trademarks of Mitsui Chemicals, Inc.

Crystal Coat is a trademark of SDC Technologies, Inc. Visgard is a registered trademark of FSI Coating Technologies. COTEC is a trademark of COTEC.

©2021 Mitsui Chemicals, Inc. All Rights Reserved.