A Revolution in Standard Single Vision Lenses

By Brent McCardle, ABO and Deborah Kotob, ABOM

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Describe the evolution of stock and semi-finished single vision lens blanks.

- Describe how ZEISS CORE Technology uses the total distance between the back vertex of the lens and the CoR (b') for the optimization of spectacle lenses.

- Explain how ZEISS ClearFormⓇ technology brings a freeform lens design to a finished stock lens.

Faculty/Editorial Board

Brent McCardle, ABOC, is a dedicated educator with 35 years of optical experience. His understanding of the optical industry encompasses all facets including training and development, teaching ophthalmic optics and advanced ophthalmic theory, managing a surfacing, finishing laboratory and dispensary.

Brent McCardle, ABOC, is a dedicated educator with 35 years of optical experience. His understanding of the optical industry encompasses all facets including training and development, teaching ophthalmic optics and advanced ophthalmic theory, managing a surfacing, finishing laboratory and dispensary.

He learned to become a better teacher and trainer while he was an Instructor at Durham Technical Community College, and he continues to train and educate ZEISS ECP's and ZEISS representatives in his role Technical Education Specialist. He is an NC licensed optician, technical speaker for the ABO/NCLE and he represents ZEISS on ANSI.

Deborah Kotob, ABOM, is the Director of Education and Training for Jobson Medical Information. Her experience spans more than twenty years in the optical industry. During this time, her roles included optical boutiques owner, optician, optical frame sales, and over ten years in lens manufacturing as a Lens Consultant, Trainer, and LMS content developer. She lectures, trains, conducts webinars on a variety of optical and practice development topics.

Deborah Kotob, ABOM, is the Director of Education and Training for Jobson Medical Information. Her experience spans more than twenty years in the optical industry. During this time, her roles included optical boutiques owner, optician, optical frame sales, and over ten years in lens manufacturing as a Lens Consultant, Trainer, and LMS content developer. She lectures, trains, conducts webinars on a variety of optical and practice development topics.

Credit Statement

This course is approved for one hour of ABO CE credit, Ophthalmic Level 2, Course#: STWJHI079-2

Support

THIS COURSE IS SUPPORTED BY AN EDUCATIONAL GRANT FROM ZEISS

Single-vision (SV) lenses get an upgrade! If you are an ECP dispensing lenses, this news should pique your interest; after all, single vision lenses represent 75 percent of all ophthalmic lenses sold worldwide.

ZEISS is the innovator behind this new freeform optimized stock and semi-finished single vision lens category. With over 100 years of optical discoveries and innovations, it is not surprising that they have set a new standard for single vision lens blanks. With the introduction of ClearView Single Vision Lenses, ZEISS sets a new benchmark for SV lenses by incorporating complex freeform lens designs into both stock finished single vision (FSV) and surfaced semi-finished single vision (SFSV) lens blanks. ClearView Freeform optimization results in excellent optics from the optical center to the lens periphery in single vision lenses that are very thin and flat, meeting the visual and aesthetic needs of the patient. The degree of improvement in visual clarity and customer satisfaction is evidenced by simulation results that shows ZEISS ClearView SV lenses provide, on average, three times larger zones of excellent vision clarity compared to previous aspheric SV lenses1 and by blind testing results showing that single vision lens wearers experience clarity and visual comfort and prefer ZEISS ClearView over ZEISS Aspheric SV lenses.2, 3

THE STANDARD SINGLE VISION CATEGORY

Standard single vision lenses are a staple item for every practice. And as the most sold type of lenses globally, whether spherical (SPH) or aspherical (AS), standard single vision (SV) is a big part of our business. The majority sold are stock finished single vision (FSV) blanks whose lower cost and fast delivery time benefit the practice and the patient. The other standard single vision lens type is the semi-finished SV (SFSV) lens blank, where the Rx is surfaced off the back of the lens (also used in freeform).

The beauty of stock FSV lenses is they are ready to edge into the frame, dramatically cutting delivery time compared to surfaced lenses. For practices with an inhouse finishing lab, they simply pull the lenses out of their inventory and edge for insertion into the patient’s frame, sometimes as the patient waits, but always faster than ordering surfaced lenses and waiting for them to be cut and shipped. Whether FSV or SFSV, ClearView lens blanks have a freeform optimized front curve to reduce oblique aberrations and improve off-axis gaze peripheral lens optics making ClearView a big win for the dispenser and the patient.

Whether FSV or semi-finished surfaced SV, most single vision lenses dispensed today are in the standard spherical or aspherical designs. Until now, the only way to deliver the best optics as the gaze rotates away from the central zone into the peripheral lens was by using premium individualized or customized freeform SV surfaced lenses. These lenses use different levels of individualized position of wear parameters and therefore compensated Rx values. While premium personalized freeform lenses deliver customized precision optics, the drawbacks of higher cost, longer lead times and higher fitting complexity resulted in a lower dispense rate. Unfortunately, most single vision lens wearers are not receiving the full optical benefits possible in their lenses. ZEISS ClearView elevates the FSV and SFSV single vision lens category, delivering many benefits of freeform optics with the simplicity, speed and cost advantage of the standard single vision category.

Whether FSV or semi-finished surfaced SV, most single vision lenses dispensed today are in the standard spherical or aspherical designs. Until now, the only way to deliver the best optics as the gaze rotates away from the central zone into the peripheral lens was by using premium individualized or customized freeform SV surfaced lenses. These lenses use different levels of individualized position of wear parameters and therefore compensated Rx values. While premium personalized freeform lenses deliver customized precision optics, the drawbacks of higher cost, longer lead times and higher fitting complexity resulted in a lower dispense rate. Unfortunately, most single vision lens wearers are not receiving the full optical benefits possible in their lenses. ZEISS ClearView elevates the FSV and SFSV single vision lens category, delivering many benefits of freeform optics with the simplicity, speed and cost advantage of the standard single vision category.

Typically, standard SV lenses are judged on their material index, anti-reflection coatings, UV or blue light-blocking properties, or how thin and flat they are. The lens power is measured in the center, but attention is rarely paid to optical performance and vision clarity across the entire lens. The result: standard FSV and SFSV lenses that do not provide great peripheral optics (Fig. 1).

WHAT YOUR PATIENTS CARE ABOUT AND HOW CLEARVIEW DELIVERS

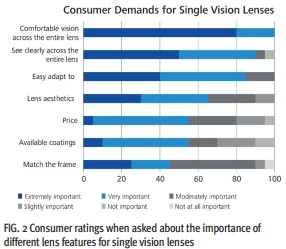

One hundred percent of wearers surveyed stated that it was extremely or very important to them that their lenses offer comfortable vision across the entire lens. Ninety percent said that it was extremely or very important for them to see clearly across the whole lens (Fig. 2).

One hundred percent of wearers surveyed stated that it was extremely or very important to them that their lenses offer comfortable vision across the entire lens. Ninety percent said that it was extremely or very important for them to see clearly across the whole lens (Fig. 2).

Why do so many SV lenses fall short of expectations in one of the most important features for spectacle lens wearers—comfort and excellent clear vision over a wide field of view?

Standard evaluation methods are ineffective for analyzing the optical performance of an ophthalmic lens or lens design. For example, measures of sphere and cylinder power in the lens center are not enough to understand the vision experienced by the spectacle lens wearer when their gaze is off axis. To assess these optical properties, it is important to map the entire lens surface and then consider the lens geometry, lens fit and the physiological metrics (e.g., the center of rotation of the wearer’s eye) all to allow for a thorough ray-tracing for the wearer relative to the position of wear. In addition, it is essential to factor in how the lens’ optical properties translate into the subjective visual experience perceived by the lens wearer. To this end, the perception of blur is particularly relevant as it impacts visual acuity and can reduce the quality of vision and visual comfort for the wearer

In general, image blur reduces an image’s perceived resolution, resulting in a relative deterioration of visual acuity and a decrease in visual performance. Image blur is a physiological-optical phenomenon that can be calculated based on defocus and unwanted astigmatism. The perception of blur by the wearer is also a psychophysical phenomenon, whereby the blur threshold is a more subjective experience that factors in the sensitivity of the observer, the demands and nature of the visual task, the image blur ratio, the contrast of the object, pupil size, ambient lighting and more. To evaluate the visual clarity experienced by a lens wearer, limits must be established for sensitivity and tolerance for the perception of blur. These thresholds can predict the optical performance, the peripheral clarity of spectacle lens designs and the clear, undistorted vision area.

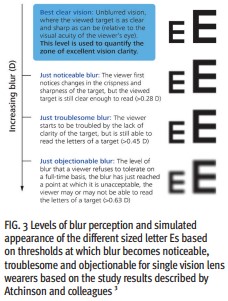

In cooperation with the Queensland University of Technology (QUT) in Brisbane, Australia, ZEISS has conducted a series of studies to define these key parameters4, 5, 6 which are then applied in a ZEISS Vision Clarity Simulation. Based on the thresholds defined in these studies, blur levels are classified into four distinct levels: the zone of excellent vision clarity providing the best clear vision, noticeable blur, troublesome blur and objectionable blur (Fig. 3).

In cooperation with the Queensland University of Technology (QUT) in Brisbane, Australia, ZEISS has conducted a series of studies to define these key parameters4, 5, 6 which are then applied in a ZEISS Vision Clarity Simulation. Based on the thresholds defined in these studies, blur levels are classified into four distinct levels: the zone of excellent vision clarity providing the best clear vision, noticeable blur, troublesome blur and objectionable blur (Fig. 3).

Vision Clarity Simulation: Building on their extensive knowledge in industrial metrology, ZEISS developed ZEISS Vision Clarity Simulation, which overcomes typical evaluation shortcomings, allowing ZEISS to thoroughly evaluate the optical performance of an ophthalmic lens or a theoretical lens design.

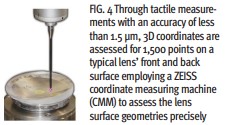

First, the lens surface of the ophthalmic lens is assessed through tactile measurement of the front and back surface using the highly precise and accurate ZEISS Coordinate Measuring Machine (CMM, Fig. 4). Secondly, the precise surface geometries are then used in a mathematical simulation, where the lens is simulated in front of a wearer’s eye, requiring the exact stated visual correction—in other words, simulating aspects of vision through the ophthalmic lens and computing the paths of particular rays entering the pupil of the eye. Next, the lens reconstruction is calculated using a proprietary software package developed explicitly by ZEISS to design and analyze ophthalmic lenses using ray tracing. Besides measurements on existing lenses, the ZEISS Vision Clarity Simulation is also used to predict and optimize the optical performance of new lens designs.

First, the lens surface of the ophthalmic lens is assessed through tactile measurement of the front and back surface using the highly precise and accurate ZEISS Coordinate Measuring Machine (CMM, Fig. 4). Secondly, the precise surface geometries are then used in a mathematical simulation, where the lens is simulated in front of a wearer’s eye, requiring the exact stated visual correction—in other words, simulating aspects of vision through the ophthalmic lens and computing the paths of particular rays entering the pupil of the eye. Next, the lens reconstruction is calculated using a proprietary software package developed explicitly by ZEISS to design and analyze ophthalmic lenses using ray tracing. Besides measurements on existing lenses, the ZEISS Vision Clarity Simulation is also used to predict and optimize the optical performance of new lens designs.

The optical properties calculated with this mathematical simulation are then evaluated based on the level of blur as subjectively perceived by the wearer. To quantify the blur of the ophthalmic lens or lens design, a single measure of dioptric blur is calculated point by point for a 50 mm diameter viewing area, combining spherical and astigmatic blur occurring due to off-axis viewing into one blur value using the RMS (root-mean-square) Power Error. In the last step of the ZEISS Vision Clarity Simulation, the area of excellent vision clarity in the field of view is quantified. The area of the lens for all eye rotations away from the center, in which the level of blur is below the threshold for “just noticeable blur” where the target is as sharp and as clear as can be. This sophisticated mathematical vision clarity simulation allows ZEISS to quantify the size of the field of view that provides excellent and undisturbed clear vision as experienced by the wearer.

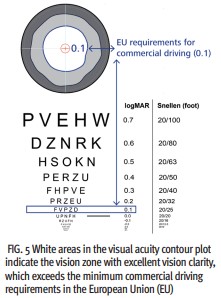

The ZEISS Vision Clarity Simulation result can be further translated into visual acuity contour plots, which graphically depict the distribution of optical blur over the lens as seen by the wearer and show the deviation from the ideal central correction toward the lens periphery (Fig. 5).

The ZEISS Vision Clarity Simulation result can be further translated into visual acuity contour plots, which graphically depict the distribution of optical blur over the lens as seen by the wearer and show the deviation from the ideal central correction toward the lens periphery (Fig. 5).

White areas on the plot indicate the vision zone with excellent vision clarity, offering excellent uncompromised visual acuity7—which exceeds the minimum requirements for commercial driving in the European Union (EU) as one example.

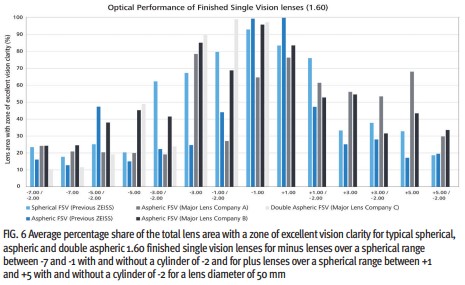

A detailed assessment of the visual clarity of typical SV lenses based on the ZEISS Vision Clarity Simulation shows most offer less than 50 percent of the lens area with a zone of excellent vision clarity and some as low as only 10 percent (Fig. 6).8 The zone of excellent clear vision is thereby defined as an uninterrupted circular area on the lens providing completely unblurred vision where viewed the target is sharp and clear as can be.

THE EVOLUTION OF SINGLE VISION LENS DESIGN

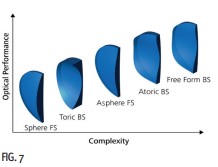

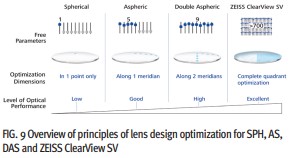

There are many types of single vision lens designs. But why do many SV lenses perform poorly with respect to their peripheral optics? The answer lies in the lens design itself. The central power of a lens can be produced by an almost infinite range of lens forms. Lens design choices impact lens aesthetics and wearing comfort but, more importantly, optical performance, particularly in the lens periphery. Better optical performance across the entire lens can only be achieved by applying a higher complexity to the lens design optimization (Fig. 7).

There are many types of single vision lens designs. But why do many SV lenses perform poorly with respect to their peripheral optics? The answer lies in the lens design itself. The central power of a lens can be produced by an almost infinite range of lens forms. Lens design choices impact lens aesthetics and wearing comfort but, more importantly, optical performance, particularly in the lens periphery. Better optical performance across the entire lens can only be achieved by applying a higher complexity to the lens design optimization (Fig. 7).

Spherical (SPH) single vision lenses are typically optimized using one free parameter in the lens center, determining the radius of the curvature of the lens surface and resulting in optical compromises away from the lens center as peripheral rays are more strongly refracted than rays near the optical axis. The spectacle lens wearer will perceive this aberration as blur, the steeper curvature, the greater the blur. Additionally, the aesthetics of the lens are bulbous and unattractive, with a steeper base curve. Spherical single vision lenses typically compromise both optics and aesthetics.

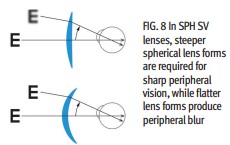

Depending on the specific design details, compared to aspheric single vision lenses optimized in only one meridian, double aspheric FSV can be an improvement. However, blending in between the two perpendicular meridians leads to optical errors for peripheral viewing when compared to freeform lens designs where some hundreds of points across the entire lens surface can be specifically optimized. Therefore spherical, aspheric and double aspheric lens designs do not adequately address the peripheral optics of most prescriptions, especially those with cylinder power. In SPH SV lenses, steeper spherical lens forms are required for sharp peripheral vision, while flatter lens forms produce peripheral blur (Fig. 8).

Depending on the specific design details, compared to aspheric single vision lenses optimized in only one meridian, double aspheric FSV can be an improvement. However, blending in between the two perpendicular meridians leads to optical errors for peripheral viewing when compared to freeform lens designs where some hundreds of points across the entire lens surface can be specifically optimized. Therefore spherical, aspheric and double aspheric lens designs do not adequately address the peripheral optics of most prescriptions, especially those with cylinder power. In SPH SV lenses, steeper spherical lens forms are required for sharp peripheral vision, while flatter lens forms produce peripheral blur (Fig. 8).

Aspheric (AS) single vision lenses are a more modern design now offered by most lens suppliers. In theory, it can provide optics as good as spherical single-vision lenses while significantly improving cosmetics. One surface, usually the front surface, is nonspherical with curves changing from the lens center to edge and typically optimized using five free parameters. One parameter defining the radius of the curvature in the lens center and 4 aspheric coefficients—but is only optimized in one meridian. To eliminate the optical aberrations completely, a unique aspheric lens design must be used for each spherical prescription power. Because this is not the case, most sphere powers have unwanted optical aberrations limiting the peripheral vision clarity. Additionally, about 70 percent of all spectacle lenses incorporate a cylinder correction for astigmatism. In aspheric lenses, the standard toric (two perpendicular spherical shapes) back surface is used for cylinder correction. In this case, the compromise on vision clarity in the lens periphery is even worse, with the front curve selection and aspheric lens designs created for one sphere power only, resulting in an increase in optical aberrations as the cylinder power increases.

Double Aspheric (DAS) single vision lenses: Some lens suppliers now offer double aspheric FSV lenses, whereby the backside of the lens provides cylinder correction using two aspheric shapes perpendicular to each other, often referred to as an atoric surface. The lens is typically optimized using 9 free parameters, 1 defining the radius of the curvature in the center and 4 aspheric coefficients in each of the two perpendicular meridians.

Freeform (FF) single vision lens designs: More recently, when ZEISS pioneered freeform technology for ophthalmic lenses, freeform single vision surfaced lenses could overcome these problems, using more complex shapes. Freeform technology means that the lens shape can be perfectly optimized to give the best optics for each individual prescription while delivering very flat and thin lenses—no more compromise. This resulted in a new class of single vision lenses. Depending on the market, these products are called Freeform, digitally surfaced, or HD Single Vision lenses—and have been available only as a made-toorder surfaced lens.

ZEISS SmartLife Single Vision lenses are the most modern and sophisticated example of freeform single vision lenses. The SmartLife SV design incorporates a 3D object model that requires knowledge of factors such as lens orientation and position of wear. The Individual version of the SmartLife design even incorporates the individualized parameters of the actual wearer in the freeform lens design, allowing an extra level of lens optimization. These are variables not possible to account for in single vision lenses that are pre-made without infinite variants held on stock.

ZEISS CLEARVIEW SINGLE VISION LENSES

ZEISS CLEARVIEW SINGLE VISION LENSES

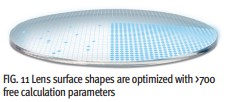

ZEISS decided to re-examine industry practices in single vision, challenging why most single vision wearers, namely those who receive standard single vision lenses could not get many of the visual benefits of freeform lens design. ZEISS has now identified a way to get these complex freeform lens designs into standard single vision, whether in FSV or surfaced SV lenses that are easy to fit without compensated Rx values. Whether delivered by FSV or surfaced SV, the advanced freeform lens design in ZEISS ClearView SV uses point-by-point optimization of the lens surface. The lens power is optimized using 700 free parameters across one entire quadrant of the lens, which is then mirrored two times to cover the entire lens surface. Complete optimization of one quadrant is the maximum possible in a pre-made lens design without knowing the exact orientation for the final fitted lens (Fig. 9). The result is an SV lens that is both very flat and thin, and achieves excellent optics with clear viewing from the lens center to the periphery.

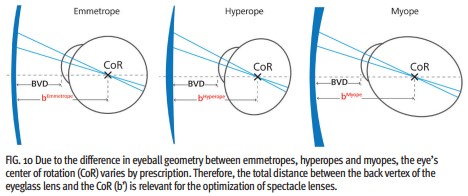

CORE TECHNOLOGY

The geometry of eyeballs differs from individual to individual. For example, a high myope typically has a 4 mm longer eyeball than someone with perfect vision. Importantly this means that the location of a special point in the eye—its center of rotation (CoR)—also varies by prescription (Fig. 10). Using an accurate position of the CoR for lens design optimization plays a vital role in the visual comfort of the wearer—in particular, allowing them to see more clearly in the lens periphery.

The geometry of eyeballs differs from individual to individual. For example, a high myope typically has a 4 mm longer eyeball than someone with perfect vision. Importantly this means that the location of a special point in the eye—its center of rotation (CoR)—also varies by prescription (Fig. 10). Using an accurate position of the CoR for lens design optimization plays a vital role in the visual comfort of the wearer—in particular, allowing them to see more clearly in the lens periphery.

ZEISS uses its medical and optical expertise to understand how the CoR changes by prescription. It is calculated by prescription using a patented algorithm generated from more than 300 precise patient measurements. The difference in CoR location from high plus through to high minus lenses is considered in the lens design with CORE technology.

The CORE technology is standard in ZEISS premium Rx lens designs. With ZEISS ClearView SV lenses, in both FSV and surfaced SV, CORE technology is available for the first time to the standard Single Vision lens category. This complexity can now be fully incorporated into an FSV lens, or non-compensated surfaced SV lens due to the use of a freeform lens design with the resulting higher level of surface complexity.

CLEARFORM® TECHNOLOGY BY ZEISS

Two methods can deliver ZEISS ClearView SV lenses.

- Surfaced SFSV ClearView lenses are madeto order, produced using the latest freeformRx lens surfacing equipment, previously usedonly for the most premium lens categories—now utilized and embraced in the standard single vision category. As a result, this equipment is becoming increasingly common in the ophthalmic industry. However, it does little good to make SPH or AS lens design with this equipment, the optical benefit onlycomes when in combination with a more sophisticated freeform lens design such as ZEISS ClearView.

- ZEISS has developed a special manufacturing method that enables complex freeform lens designs to be delivered in FSV lenses—ZEISS calls this revolutionary production advancement ClearForm® technology. This technology is possible thanks to extensive collaboration between ZEISS global centers of excellence: lens design and industrial metrology in the ZEISS headquarters in Germany, freeform mold generation in ZEISS’ European glass mold-making center of excellence and casting development collaboration between international R&D and manufacturing locations. ClearView FSV lenses are produced to stock and held in ZEISS market stocking points or at customer locations, meaning faster delivery time to customers.

The ClearForm® technology can be summarized in seven steps:

The ClearForm® technology can be summarized in seven steps:

1. ClearView “Freeform” lens design (Fig. 11): Optical lens design experts in ZEISS R&D use complex mathematical simulation tools to design the sophisticated freeform optics in ZEISS ClearView lenses. Surface shapes are optimized using >700 free calculation parameters—producing much more complex lens surface shapes than those used in spherical or aspheric single vision designs. Finally, the complex ClearView lens surface design is transferred into mold designs used in the FSV manufacturing process.

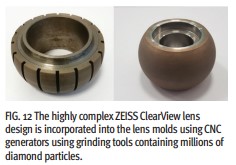

2. Freeform glass mold making (Fig. 12): Computer numerically controlled (CNC) freeform mold generators use special cutting tools that contain millions of diamond particles. These can produce virtually any moldshape in optical glass with a very high degree of accuracy. The worked mold surface is then polished to a very high luster by highspeed rotating polishing spheres to ensure the final cast lens will be of the highest optical quality.

2. Freeform glass mold making (Fig. 12): Computer numerically controlled (CNC) freeform mold generators use special cutting tools that contain millions of diamond particles. These can produce virtually any moldshape in optical glass with a very high degree of accuracy. The worked mold surface is then polished to a very high luster by highspeed rotating polishing spheres to ensure the final cast lens will be of the highest optical quality.

3. Mold metrology (Fig. 13): Using ZEISS’ industrial metrology expertise, final molds are checked for accuracy and precision withZEISS coordinate measuring machines (CMM) where over 1,500 points on the mold’s surface are analyzed, confirming a match to the theoretical freeform design.

4. Specialized mold pairing and filling (Fig. 14): For each prescription/SKU, front and back molds are paired and assembled. The molds incorporate 2D Data Matrix Codes (DMC) as part of an industry 4.0 manufacturing process that tracks molds, lenses and quality systemaics. The mold assemblies are filled with UVProtect or BluGuard lens liquid monomers across multiple refractive indices.

4. Specialized mold pairing and filling (Fig. 14): For each prescription/SKU, front and back molds are paired and assembled. The molds incorporate 2D Data Matrix Codes (DMC) as part of an industry 4.0 manufacturing process that tracks molds, lenses and quality systemaics. The mold assemblies are filled with UVProtect or BluGuard lens liquid monomers across multiple refractive indices.

5. Polymeric thermal cure: Specially developed thermal “curing” processes areused to turn the liquid monomers into optical grade polymer materials. Precisely controlling the different chemical curing reaction kinetics for each material is critical. Thus, ensuring the optical shape is perfectly transferred from the mold to the final cast lens without error or distortion. After the curing cycle that takes up to two days is complete, the glass molds are removed, and thelens shape is now set.

6. Hard and anti-reflective coatings: The lensesare coated with tough and abrasion-resistant hard coating. ZEISS DuraVision anti-reflective coatings are then deposited in vacuum chambers. Next, ion bombardment is used to deliver densely packed coating layers. This combination of state-of-the-art hard coat and AR technology ensures excellent coating performance and long-lasting durability.

7. And for the final lens optical check: The precise surface geometries of the finished lens is checked at over 1,500 points by ZEISS CMM equipment and then used in optical ray path simulations to ensure the finished lens delivers on the superior optical promise required of ZEISS ClearView FSV lenses.

7. And for the final lens optical check: The precise surface geometries of the finished lens is checked at over 1,500 points by ZEISS CMM equipment and then used in optical ray path simulations to ensure the finished lens delivers on the superior optical promise required of ZEISS ClearView FSV lenses.

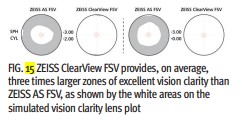

The optical performance of ZEISS ClearView FSV lenses was analyzed based on the ZEISS Vision Clarity Simulation to guarantee that the lenses deliver high optical performance as designed. This analysis comprehensively shows that over a range of prescriptions, with minus and plus powers, ZEISS ClearView FSV lenses provide, on average, a three times larger zone of excellent vision clarity compared to regular ZEISS Aspheric FSV lenses, with a maximum improvement of over five times.1 This means clear vision over a larger lens area for all single vision wearers, allowing more comfortable vision and leading to satisfied wearers. The zone of excellent clear vision is defined as a continuous circular area of unblurred vision on the lens—below the threshold for noticeable blur. Fig. 15 shows two example plots of the simulated vision clarity levels for a 1.60 index ZEISS ClearView FSV lens with and without a cylinder, compared to a regular 1.60 Index ZEISS Aspheric FSV. In this example, the ZEISS ClearView FSV offers a three (with cylinder) to four (without cylinder) times larger zone of excellent vision clarity, as shown by the white areas on the lens plot.

The optical performance of ZEISS ClearView FSV lenses was analyzed based on the ZEISS Vision Clarity Simulation to guarantee that the lenses deliver high optical performance as designed. This analysis comprehensively shows that over a range of prescriptions, with minus and plus powers, ZEISS ClearView FSV lenses provide, on average, a three times larger zone of excellent vision clarity compared to regular ZEISS Aspheric FSV lenses, with a maximum improvement of over five times.1 This means clear vision over a larger lens area for all single vision wearers, allowing more comfortable vision and leading to satisfied wearers. The zone of excellent clear vision is defined as a continuous circular area of unblurred vision on the lens—below the threshold for noticeable blur. Fig. 15 shows two example plots of the simulated vision clarity levels for a 1.60 index ZEISS ClearView FSV lens with and without a cylinder, compared to a regular 1.60 Index ZEISS Aspheric FSV. In this example, the ZEISS ClearView FSV offers a three (with cylinder) to four (without cylinder) times larger zone of excellent vision clarity, as shown by the white areas on the lens plot.

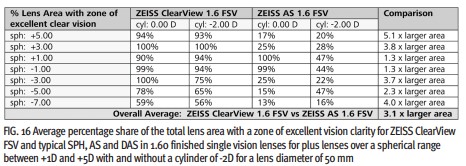

On average, ZEISS ClearView FSV lenses offer a 3.1 times larger area with a zone of excellent clear vision compared to previous ZEISS AS FSV lenses, with up to a four times larger area for higher myopic prescriptions and up to a 5.1 times larger area for higher hyperope prescriptions.1 (Fig. 16)

ZEISS also double checked the performance of ZEISS ClearView FSV lenses compared to FSV lenses from other major branded lens companies. Similar magnitudes of performance improvement can be seen for ZEISS ClearView FSV relative to AS and DAS FSV lenses from other major branded lens companies.1, 9

Reduced optical distortion: In addition to less optical blur, ZEISS ClearView SV lens designs also provide reduced peripheral distortion compared to standard SPH or AS single vision lenses. The total magnitude of the distortion effects in the lens design of ZEISS ClearView compared to typical single vision lens designs was summarized by ZEISS lens designers. Based on simulation calculations on different types of distortion typically encountered by spectacle lens wearers, ZEISS ClearView lens designs showed, on average, over 4 percent less skew and swim distortion than a regular SPH SV lens and 10 percent less than a standard AS SV lens.10

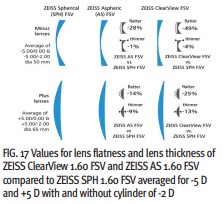

Thinner lenses (Fig. 17): With ZEISS ClearView SV lenses, wearers can experience excellent vision clarity in a flatter and thinner lens than conventional lenses that rely on steeper base curves to provide acceptable optical performance. Freeform SV lens designs with point-bypoint optimization provide a thickness reduction at the lens edge for minus lenses. Across the range of plus lenses, which are thicker in the lens center, 1.60 ZEISS ClearView FSV is on average 8 percent thinner at the lens center and up to 13 percent thinner at the lens center for +5.00 D sphere power, when compared to 1.60 ZEISS SPH FSV.13

Thinner lenses (Fig. 17): With ZEISS ClearView SV lenses, wearers can experience excellent vision clarity in a flatter and thinner lens than conventional lenses that rely on steeper base curves to provide acceptable optical performance. Freeform SV lens designs with point-bypoint optimization provide a thickness reduction at the lens edge for minus lenses. Across the range of plus lenses, which are thicker in the lens center, 1.60 ZEISS ClearView FSV is on average 8 percent thinner at the lens center and up to 13 percent thinner at the lens center for +5.00 D sphere power, when compared to 1.60 ZEISS SPH FSV.13

Flatter lenses, with no optical compromise (Fig. 17): The technological advances in ZEISS ClearView SV also allow for flatter, more attractive lenses by reducing the curvature without compromising vision clarity in the lens periphery. In the FSV form, this results in, on average 34 percent flatter lenses across all prescriptions, with up to 49 percent flatter lenses for the minus range; and up to 25 percent flatter lenses for the plus range, when compared to ZEISS SPH 1.6 FSV.14

Across the entire power range assessed, ZEISS ClearView FSV lenses are 34 percent flatter and up to 16 percent thinner than standard SPH SV lenses while delivering the highest level of vision clarity

SINGLE-VISION LENS WEARERS CONFIRM THE DIFFERENCE

Larger zones of excellent clear vision allow higher levels of visual acuity across the entire viewing zone for the wearer, meaning single vision wearers will see more clearly and be more comfortable wearing ZEISS ClearView SV lenses than standard SV lens designs. This was confirmed firstly by a small blind test wearer trial.15, 16 After one week of wear, 78 percent of study participants preferred the vision performance of ZEISS ClearView compared to ZEISS AS FSV, and 89 percent strongly agreed or agreed that they had experienced all day visual comfort with ZEISS ClearView. Immediately after receiving the lenses, by 2 to 1 single vision lens wearers preferred ZEISS ClearView for seeing clearly across the entire lens when compared to wearing ZEISS AS FSV lenses in visual testing scenarios for near, intermediate and distance vision. Eighty-nine percent of study participants rated the immediate impression with ZEISS ClearView as good or very good. A subsequent much larger double blind wearer trial was conducted by an eye hospital.17 Across 185 SV wearers and 19 tested viewing scenarios, ClearView was preferred for clear vision across the lens, comfort and general preference. As the refractive power of the lens increased, the relative preference for ClearView was even greater. In the group of wearers with both moderate sphere and cylinder power, this preference increased to 87 percent compared to AS FSV. These wearer trials evaluated the subjective impression of vision clarity, vision comfort, preference and satisfaction.

Clearview’s single vision lens performance was outstanding, as clearly shown by these wearer trials and supported by objective measures that show on average, ZEISS ClearView FSV lenses offer a 3.1 times larger area with a zone of excellent clear vision when compared to previous ZEISS AS FSV lenses. As we have come to expect, ZEISS gives us the research and data; we need to make informed decisions, and they make it an easy choice for us to upgrade our single vision patients’ visual experience.

Sources provided upon request.

Information contained herein regarding any specific product, manufacturer, or otherwise, does not constitute or imply its endorsement by ABO and NCLE.