Identify the problem, understand the technology and use the tips for better solutions. Many of these solutions and tips are short enough to use directly with the patient, once you’ve identified their problem.

At the Dispensing Table

- Problem: Discomfort recommending AR on high-index lenses because of the cost of high-index when compared to plastic (especially in a tight economy).

Solution: High-index materials reflect more than standard plastic. In order for the patient to see their best, high-index lenses in particular need anti-reflective surfaces.

Tip: Always recommend lenses in the best form they are available. Consider bundling high-index and AR together; refer to them as AR lenses and not as lenses with an AR “coating.”  Problem: High-plus plastic lenses bulge and can push out of a frame, upsetting the patient.

Problem: High-plus plastic lenses bulge and can push out of a frame, upsetting the patient.

Solution: Because plus lenses are thick in the middle and thin at the edge, they can change the shape of the top eyewire. Flatter, aspheric lenses, especially high-index, present a sleeker profile.

Tip: Use a lens that is both aspheric and high-index. The frame with lenses will be more natural in shape and the eyewear will look better too. Problem: Plus lenses magnify the wearer’s eyes, resulting in an odd appearance.

Problem: Plus lenses magnify the wearer’s eyes, resulting in an odd appearance.

Solution: Flattened aspherics reduce pincushion distortion of plus lenses by flattening the front surface of the lens reducing magnification.

Tip: Aspheric lenses reduce magnification of plus powers, patient’s eyes are more natural in size and they just look better.- Problem: I ordered premium, high-index minus lenses but they still came out very thick at the edge.

Solution: Decentration, (when the PD is much smaller than the distance between frame centers, DBC) can cause temporal lens edges to be thicker. In addition, frame shapes that have high corners, like cat-eye shapes, will also require larger lenses since larger diameter lenses are needed.

Tip: Improve the lens-frame combination by making the DBC and PD similar; also consider long corners and the power along those axes.  Problem: Uncertain whether or not to offer wrap sunglasses for a given minus prescription.

Problem: Uncertain whether or not to offer wrap sunglasses for a given minus prescription.

Solution: Most wrap frames require steeper lenses than may ordinarily be used—think -3.00 or more. These Rxs have flatter front curves. Using the correct lens flatness will change the shape of the frame so you must use steeper lenses.

Tip: Use a lens clock to check the base curves of the original plano lenses in the sunglasses. Order the Rx with a base curve that is 1 to 2D flatter than the frame and order prism to compensate for the prism that the lens will create at the wrap angle. Rule of thumb: order 0.2 prism diopters Base In for lens powers less than +/-2.50D at the 180 meridian; order 0.37D for powers above 2.50D.- Problem: The patient is unhappy. Their plus lenses in the new grooved rimless frame are several millimeters thick at the nose.

Solution: Grooved rimless frames require a minimum edge thickness for the grooving, which means plus becomes thicker in the nasal when decentered.

Tip: Consider aspheric, high-index lenses (reduced thickness), with minimal decentration (again reducing thickness), in a full-rim frame (hides the lens edge). - Problem: Polarized lenses in a frame show an irregular pattern around the edges in some lighting situations.

Solution: Polarized lenses may display their own stress pattern, something visible to the naked eye. When in doubt regarding stress on lenses, use a colma- or polariscope to check for stress. A laptop or flat screen monitor may also substitute because its screen is polarized and will highlight stress in lenses when viewed through them.

Tip: Be sure screws are not over-tightened and lenses are not bent or have been made too large for the frame. - Problem: The patient asks how thick the edges of his lenses will be in the frame.

Solution: The patient is clearly concerned about the visibility of their lenses. Obtain the best possible results through reduced decentration, rounded corners, high-index, AR lenses. Look at their current eyewear—can you improve on it?

Tip: Tell patients that good proportions and good choices deliver the best results. Also, use lens charts that show the edge or center thickness of powers equivalent to their prescription. - Problem: The patient wants a wrap, PAL polarized pair of glasses for motorcycle riding but it’s uncomfortable presenting so many premium options.

Solution: Determine the best lens choice for motorcycling. The patient may get better results with distance vision in a riding pair and a PAL in a dress pair.

Tip: Determine patient use before presenting options. Present motorcycle eyewear as best available equipment, similar to helmet, riding apparel and the motorcycle itself. Patients will thank you for presenting the best to them so they may safely pursue their avocation.  Problem: My staff is eager to learn, but not interested in sitting for a certification exam.

Problem: My staff is eager to learn, but not interested in sitting for a certification exam.

Solution: Determine the areas needing improvement and the items of staff interest. Develop a plan and goals for each staff member.

Tip: Contact lab and manufacturer lens consultants, technical services and your frame reps; they are able to present information and teach new concepts in your own office. Visit www.2020mag.com for a suggested curriculum and educational courses.- Problem: The patient asks about tints to protect their children’s eyes outdoors.

Solution: They’re right about wanting to protect children’s eyes. Studies suggest that individuals are exposed to 80 percent of the accumulated lifetime UV radiation by the time they are age 18. UV absorbing, photochromic lenses are a great tool to prevent UV from entering the eye and they add comfort in all light conditions.

Tip: Photochromic polycarbonate or Trivex lenses are ideal for kids of all ages. Unlike a tint, photochromic lenses are clear indoors and darken as needed while always blocking harmful UV rays. - Problem: Today, patients may be asking for the least expensive option possible and don’t want to hear about AR.

Solution: Regardless, match the spectacles to the patient’s needs and explain the options. You may inquire, “Do you deal with a lot of people in the course of a day? AR lenses present a better image and you’ll experience less eyestrain, too.”

Tip: Present the best options to patients, they’ll make the final choice and you’ll be more confident. - Problem: You received glasses back from the lab with the patient’s new +1.00 Rx and prescribed 3D Base Out prism in the patient’s own grooved rimless frame. The patient is unhappy with the appearance. The Base Out lens is thicker on the temporal edge than their previous lenses.

Solution: Plus lens, Base Out requires that the lens’ optical center is moved out so the edge of the lens will become thicker. In their previous lenses, the lenses were made for the minimum edge thinness possible and contained no prism. The best way to minimize the thinness of the prism is with high-index lenses and a frame that will mask the thickness.

Tip: Envision the look of the lenses first before frame selection, and then choose an appropriate frame. A thicker eyewire or zyl frame will help cover the lens edges. High-index would make the lenses look more similar. This is a good job to discuss with your lab.

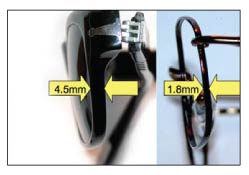

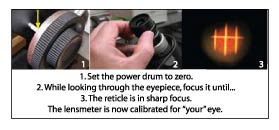

In the Lab - Problem: Inconsistent powers using a manual lens meter, lens-to-lens, optician-to-optician.

Solution: Each optician should begin by calibrating the lens meter to his or her own eyes. Set the power drum to zero, plano. Rotate the eyepiece until the target is crisp.

Tip: When checking lens power, rotate the power drum toward more plus, not back and forth. Turning toward minus makes your eye add plus power, turning the drum toward plus prevents accommodating. Do this and lens meter skills will improve.  Problem: Unable to find the optical centers of lenses (OC) because the lens has no power along the 180 (horizontal) meridian when trying to confirm the PD?

Problem: Unable to find the optical centers of lenses (OC) because the lens has no power along the 180 (horizontal) meridian when trying to confirm the PD?

Solution: In some prescriptions, like +1.00 -1.00 at 90 will read plano power along the 180. This is because Rxs have only the sphere power at the axis and the sum of the sphere and cylinder 90 degrees from the axis. That’s because the cylinder has no power along its axis and 100 percent power 90 degrees away.

Tip: Use other reference points if available; on progressives, dot the semi-visible engravings, the segments on bifocals will provide a near PD. For single-vision lenses ensure that vertical imbalance is within tolerance and, if there is no power at the 180, apply the limit of 0.66 prism diopters tolerance to accept or reject the glasses.- Problem: How do I verify the Rx in a wrap frame when the order says “Compensated Rx”?

Solution: When an Rx is added to a wrap frame and is measured on a lensmeter, there is prism present. This is okay, it’s the prism necessary to cancel the prism that would be created by an ordinary lens at the wrap angle of the frame. Also, at this angle, an ordinary lens would change power. Labs that compensate the Rx change the power so that the patient “sees” the Rx as it was prescribed.

Tip: Use labs that have special wrap Rx programs or partner with wrap sunglass manufacturers. Those labs provide the “Compensated Rx” on the invoice. Use this to verify the Rx. - Problem: We need to know whether our 75mm finished lens inventory will be large enough for the sunglass frame chosen—the patient needs them in an hour.

Solution: The Minimum Blank Size (MBS) formula helps you know the smallest lens needed. It is MBS = Effective Diameter + 2 x Lens Decentration. Add the Effective Diameter to twice the amount of decentration for each lens.

Tip: Use the Minimum Blank Size formula. Always know what is possible before the patient leaves. - Problem: A pair of high-index lenses, power about -9.00, has very thick edges and is too visible for the patient in the plastic frame chosen.

Solution: Removing material from the back of the lens using a hand stone may help for a perfect fit or you may need a specialized bevel. Call your sales rep if unsure which jobs your in-house edger can deliver properly. Your lab supplier should also be able to help you.

Tip: Some lab work is better sent out to specialists. Many times thick lenses and plastic frames can require a specialized edger for a bevel different from the standard “v” hide-a-bevel. - Problem: An Rx of +0.25- 0.25x 180 made with stock, finished plastic lenses, in a grooved rimless frame, are chipping at the edges.

Solution: Finished lenses may be too thin at the edge to have enough thickness for the groove (about 0.6mm width) and wall thickness so the plastic won’t chip (needs about 0.9mm width). This means that 2.4mm is about the right edge thickness required. If a thinner lens is preferred, consider polycarbonate or Trivex because of their “anti-chip” properties.

Tip: Order lenses and tell your lab that the frame is a grooved rimless. Thicker edge lenses (2.2 to 2.5mm) help with chipping. For thinner lenses also at the edge, consider polycarbonate or Trivex. - Problem: Your patient has just noticed that her polarized lens has a white edge around it in the frame, particularly at the top.

Solution: Polarized lenses are clear and it’s the polarizing film that gives them their color. As a result, the lens portion in front of the film and behind it is transparent. Plastic polarized lenses can be tinted at the edges by a very quick dip in the same color as the film (poly lenses cannot be tinted on the edge since the material is not tintable but color pens can be used). Also, request the bevel closer to the front so that a minimum lens edge sticks out the front of the frame.

Tip: When edging polarized, adjust the location of the bevel closer to the lens front. Add tint to the edge for tintable materials or color pens for polycarbonate.

Timothy Coronis, ABOC-NCLE, is an American Board of Opticianry technical speaker and freelance author. As an independent continuing education provider he can deliver credits in your office or speak at your next meeting. He may be reached at [email protected].