BPI is one of the most recognized brands in the optical industry. But even if you haven’t heard of it, you have probably used some of its products. Under the direction of BPI’s founder, Dr. Herbert Wertheim, the Miami, Fla.-based company invented the first tinting systems for optical laboratories and professional offices. Every major lens manufacturer recommends BPI tints and procedures. Virtually every major sunglass manufacturer and laboratory uses BPI tints and products. BPI invented the first gradient lenses and instruments to produce single and double gradients, the first UV tints for CR-39 and other plastic lenses, the first molecular catalytic tints for CR-39 and all other plastics, the first chemicals to be used for the rapid removal of AR coating, and the first neutralizer for removing color from CR-39 and specialized coatings. BPI’s products are not only used throughout the optical industry; more than 80 percent of camera filters and military special lenses and optics depend on BPI technology.

Now in its 38th year in business, BPI continues to innovate. Its TurboTinter, the newest technology in tinting instruments, uses infrared light to heat the surface of the lens and solution to obtain the darkest sun lenses in the shortest period of time with virtually no rejects due to spotting, streaking or color mismatches when using BPI tints.

L&T editor Andrew Karp recently talked to Dr. Wertheim about BPI’s role in developing some of the optical industry’s most popular and influential products, as well as the factors that helped shape his career.

L&T: You are one of the most successful optometrists ever, at least from a business standpoint. How does your optometric training inform your approach to business?

Wertheim: Optometry, along with my engineering education from the University of Florida, four years in the Navy as a researcher and aviator, and my years at NASA at Cape Canaveral in manned space flight, prepared me to understand the neurological and physiological needs of the eye to maintain good eye health and vision.

Plastic lenses started becoming popular in the early 1970s. When did you realize that plastic was the future, and what convinced you of that?

When I was in optometry college, the only lenses we prescribed were glass lenses. An experimental research project with American Optical was to prescribe their new CR-39 molded plastic cataract lenses. This piqued my interest in trying to make these into sun lenses. That was the first time I thought about the tinting of plastic lenses. When I opened my own practice I was impressed with the benefits of CR-39 and began to experiment with different methods of tinting cataract lenses and then other types of lenses as they became available for dispensing. (CR-39 monomer by PPG Industries has become the most widely used plastic for spectacle lenses—20/20)

BPI has been a pioneer in cosmetic and therapeutic lens tints. What were some of the challenges you faced in creating these breakthrough products, on both a technical level as well as on a marketing level?

My first experiments were in 1967 in tinting lenses shortly after obtaining my Florida license to practice. The difficulties were many. CR-39 lenses were made using several different formulas for casting. As a result, they all tended to color differently, with different tinting times and very little uniformity from lens to lens. Our team and I developed our Molecular Catalytic Tints that would finish polymerizing the lens surfaces. The tints also had a dispersion of different size chromaphores to fit into the differing openings on the surface of the lens. This was the first time that lenses from a different batch and different manufacturers could be used to produce sunglasses.

Among the various therapeutic tints that BPI produces are ones designed to help people with dyslexia. How has your own experience with dyslexia influenced BPI’s research and development of these tints?

My first work with tints for dyslexia came from my research in micro nystagmus motions in freshman college students who had reading difficulty in 1967 to 1971 at the community college in Miami. I found that certain tints were able to ameliorate these conditions. This was the beginning of the many different therapeutic tints that were used to improve their reading and comprehension as reported by the students and their faculty members. I eventually found the correct therapeutic tint that made reading easier and increased my attention span. Thousands of practitioners and educators have used our technology and tints to help hundreds of thousands of students and others that have a need for prolonged reading.

Didn’t BPI also pioneer tints for computer vision syndrome?

Yes, BPI was the first to introduce safety office tints for persons working on computer terminals and office work. Uvex, a German company, has been licensed to produce these for world use. There is a complete computer program for determining which of four different tints are the best suited for each person tested. Reading speed and comprehension is measured before and after the tint is recommended by the computer diagnostic program.

Today, the necessity of protecting one’s eyes from exposure to UV and damaging blue light is widely accepted in the eyecare field. But when BPI first introduced UV blockers and other protective tints, many eyecare professionals were skeptical of your claims that these products would provide ocular protection. What was your reaction to these responses? How did you prove your products actually worked, and how did you go about educating the market about their benefits?

My research at the Bascom Palmer Eye Institute in the early 1970s with a team of researchers doing single cell responses on kitten retinas required very bright stimulus lights. This research led to the confirmation that patching the good eye in young children would force the weak eye to become stronger. The kitten eye would soon become unstable. I suggested at that time that we place a UV filter in front of the kitten’s eye that was being tested, and we were able to double and sometimes triple the time the eye would stay clear and usable. That is what led me to begin my research in the literature about the harmful effects of UV light. My team and I were the first to produce and recommend the use of BPI Diamond Dye 400, which is still the finest protection available. It is the only UV protection that absorbs more UV light the longer it is exposed to the light source. Its unique crystal structure is such that if left in the solution for an extended period of time, it will cause the CR-39 lens to become crystallized. In our first ads, we ran the headline “What you don’t see may blind you.” This was the first advertising declaring the need for UV tints and protection.

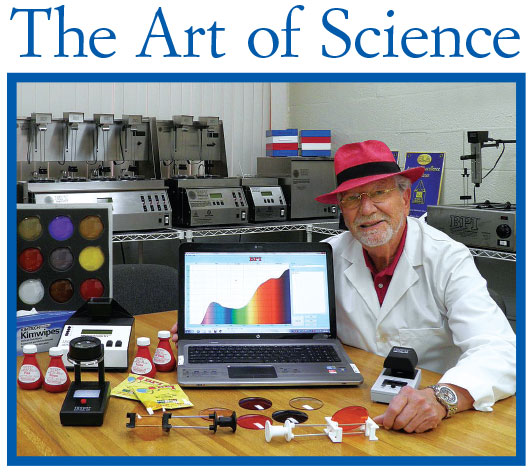

BPI has always emphasized the science behind its products. In fact, its ads typically show scientists, including you, dressed in lab coats. What are some of the most important research to emerge from BPI, and which products are the direct results of that research?

Since 1967, our team of more than 25 PhDs including engineers, chemists, safety and environmental scientists and quality assurance personnel has delivered the finest products available anywhere in the industry. BPI has been granted more than 100 patents, trademarks and special spectral copyrights.

How much are you still involved in BPI’s research?

I am still involved in the laboratory research and quality and safety assurances. I still lecture to professionals about BPI technology and science.

BPI sells over 4,000 different products ranging from lens tints to tinting systems, lab equipment and supplies. What products are you most proud of? Which ones have had the most impact on the industry?

Without question, the invention of the first UV tint and bringing attention to this serious eye health issue. Our new therapeutic tints for macular degeneration and the ones for repressing epilepsy, Parkinson’s and other neurological eye and brain conditions.

What’s the Wertheim Factor, and how is it used?

The Wertheim Factor is a figure of merit ranging from 0 to about 0.5 which represents the fraction of the damaging high-energy spectrum blocked by a lens compared to the visible transmission of the lens. High Wertheim Factor indicates a lens that blocks well in the UV-violet-blue range while transmitting well in the green-yellow-red range that is most easy to see and least damaging.

In addition to lens tints, BPI’s technology for coloring plastics is used in a wide range of industries. What are some examples?

Aircraft lighting, camera filters, windshields, agriculture, forestry, automotive and spectrum analysis.

As a successful entrepreneur, you’ve donated millions of dollars for medical research, and a medical school is named in your honor. What motivates and inspires your philanthropy?

My wife Nicole and I have been blessed with good health, a wonderful family and one of the finest educations and opportunities to use it.

Preventative medicine is one of the main themes of our family and our foundation. We have contributed to zoos, public radio and TV. We have helped fund the 1,000-seat Wertheim Performing Arts and teaching facilities at Florida International University. The Herbert Wertheim College of Medicine and The Nicole Wertheim College of Nursing and Health Sciences are our most recent endeavors. Our foundation and family have donated more than 60 million dollars during the 35 years of our foundation. Plans are being formulated for many more large projects to fund. ■