By Barry Santini

For most of spectacle history, people purchased glasses as an already assembled complete vision aid. Eyeglass “consumers” sampled a variety of lens strengths until they found one that complemented their vision. But would any contemporary eyecare professional suggest this approach when choosing proper prescription eyewear? I think not. Yet, many optical offices remain content to place their lens and spectacle orders using a comparatively similar system. Conceived over half a century ago, the use of PDs, OC and seg heights, along with basic boxed frame dimensions, are still used today to place a spectacle order via fax or phone. The familiarity and comfort of this method has helped prevent many ECPs from seeking better ways of placing their orders; for example, such as via one of the latest electronic ordering portals or ELOPs. But since electronic ordering portals originally developed some 20-plus years ago, those still in use today lack the user-friendliness and sophistication needed to create the best pair of glasses using the most advanced free-form lenses. As today’s eyeglass consumer becomes increasingly sophisticated in their optical knowledge and eyewear desires, they are frequently telling ECPs what they WANT, and less interested in a strictly one-way conversation where they’re told what they NEED. So every ECP must up their knowledge now to stay relevant in today’s optical marketplace. One of the best ways is to move beyond fax and phone ordering, and tap into the power of an advanced electronic lens portal. Let’s review a short history of spectacle making to fully understand the power and sophistication of today’s ELOPs.

THE EARLY ART OF MAKING GLASSES

Starting in the early 14th century with the founding of the Guild of Venetian Spectacle Makers, the art of making glasses and all the hard-won knowledge of glassmaking was kept very secretive. Originating in the regions of Venice and Murano, and dating back to the time of the Roman Empire in the 8th century, this area has long been known as the world’s center for the art of glass making.

PUSHCART COMMODITY

Spectacles were available in the United States starting in the early 1800s. Initially imported by the Philadelphia firm of McAllister and Sons, in 1815, McAllister transitioned to making frames domestically in the U.S. They became the largest frame maker in the country until the 1860s. During the 1800s, spectacle correction was primarily for presbyopia and myopia, and people viewed spectacles as a marker of deficiency. Frame styling evolved to make them thinner and less visible, and the monocle, rimless, pince-nez styles became the most sought-after styles. As domestic manufacturing increased during the industrialization of the mid-1800s, the price of spectacles dropped as they became viewed as a commodity. By the early 1900s, immigrant optical pioneers like Hyman Moscot, the founder of Moscot Optical, started selling assembled spectacles from pushcarts in the Lower East Side area of New York City.

SCIENCE IS ADDED

As the 20th century unfolded, the scientific approach turned its focus to the process of designing lenses and in the examination for visual defects. In the first half of the 1900s, science began to elevate the tasks of examining, fitting and making glasses, each of which expanded, evolved and became robust separate disciplines in their own right. Now with an optician’s eye, let’s review how eyeglasses were measured and fitted in the first half of the 20th century.

FRAME FITTING

From 1920 to approximately 1940, frame styling mainly comprised round, oval, hexagon and other symmetrical shapes. The 1930s were the heyday of metal and rimless frames. Choosing the proper frame was accomplished using the datum system, guided by the following workflow:

1. Determination of the correct bridge fit and size.

2. Using the binocular PD, a target lens size was chosen, guided by the need to avoid any decentering of the lenses in the finished glasses. Sometimes decentering was unavoidable because of the need to fit the facial width of the wearer. In higher-powered prescriptions, even these rules were flexible, depending on the specific job at hand.

3. The optical center position was set vertically at the “180,” which is the line co-parallel with the vertical midpoint of the frame shape. This 180 line is also the measuring point for determining bridge fit. Frame sizes and styling of this time remained small, mainly because lens blanks of the time were equally small in diameter, and lens cost was directly tied to blank size. Opticians positioned the frame front with zero pantoscopic tilt. The optical centers were mounted right before the pupil—a perfect visual fit even by today’s sophisticated standards.

The datum fitting system, created by the U.K. firm of Cole and Blackburn in 1935, was ideal for these symmetrical genderless lens shapes. The layout and ordering of glasses therefore had a simplified structure, because the datum fitting system correlated very closely with how glasses were measured and fitted. But the datum system was about to encounter a new challenge, driven in part by women’s desire for new and novel female-specific frame shapes.

FASHION CREATES NEW

CHALLENGES

As the 1940s unfolded, artists such as Altina Schinasi started experimenting with frames of unusual and unsymmetrical proportions inspired by the harlequin carnival masks of Venice. Around this time, the optical visionary Monroe Levoy, founder of the frame company Tura, directed his business efforts toward selling and styling glasses featuring the latest in feminine eyewear fashion: The CatEye. In the new CatEye frame shapes, the frame center was no longer located routinely on the pupil. With these frame shapes, the lens’ temporal point was higher and broader than the point nominal to the “180,” or pupil position. These asymmetrical shapes posed challenges to both lens layout using the datum system and the edging equipment of the time. These edging challenges were first addressed by Arthur Lemay, who, along with his nephew Joseph Santinelli, created the first automatic edging equipment capable of edging the new elongated frame shapes. Subsequently, Santinelli went on to found the successful optical company Santinelli International.

As the 1950s dawned, optical labs were increasingly faced with the problem of determining the smallest glass lens blank that would lay out at the target PD with the new CatEye frame shapes. If a finished off-the-shelf lens of the appropriate diameter was too small, then it would have to be custom made or surfaced by the lab. This further increased eyewear cost. Therefore, knowing the exact minimum blank size for a spectacle order kept costs down and helped ensure the glasses’ plus-powered prescriptions were as thin and lightweight as possible. In this “golden age” of glass lenses, cost and weight savings meant everything, since most of the public did not want to wear glasses, let alone expensive or heavy ones.

Meanwhile, at Winchester Optical Laboratory in Elmira, N.Y., owner Tom Lynch began publishing a “Lens and Frame Information” book that featured specific frame information on all the latest eyewear styles. It later featured an employee’s idea to “box” unsymmetrical lens shapes to better determine the smallest blank size needed for that order. The Lens and Frame information book, combined with this new way to mark sizes, evolved to become our current boxing system of frame measurements. The boxing system became standard in 1961 after being codified by the American Optical Manufacturer’s Association—the predecessor to the Optical Manufacturer’s Association and today’s The Vision Council.

ORDER PROCESSING EVOLVES

After the 1960s, the next significant development in how glasses were ordered occurred with the introduction of frame tracing technology, which digitized a frame’s unique shape. Armed with more precise shape information, it became easier to determine the best prescription lens thickness and blank size required. Digital frame tracing became especially important as most eyeglass orders, even today, lacked a critical piece of frame information: the axis, or direction of the radius that determines the lens’ effective diameter, also known as the ED. Using digitized frame tracing, the axis of the lens’ ED is always present. As lab management systems (LMS) became more sophisticated and assembled a digital library version of Tom Lynch’s Lens and Frame book, spectacle making finally transformed from a centuries old handmade craft to a finely tuned manufacturing endeavor.

The ordering and making of glasses were finally as precise as the optics of the finest lenses!

THE PATH TO THE FINEST LENSES

During the first 600 years after its invention in 1275, making spectacles was an empirical science—that is, new lens types were evaluated through a trial-and-error approach, using one’s senses to determine what worked. It wasn’t until the late 19th century that mathematical ray tracing was applied to improve lens performance. Names like Gullstrand, Tscherning and Ostwalt used scientific calculations to build upon the empirical work of earlier researchers like Wollaston and Petzval. By the second decade of the 20th century, Dr. Moritz von Rohr of Carl Zeiss created a lens that would become the pinnacle of the single-vision lens optics for almost 90 years: the Zeiss Punktal. Subsequent production-friendly refinements resulted in new, less costly corrective curve designs from Bausch & Lomb, American Optical and Shuron—whose “Best Form” series lent us its name for this category of lenses. Over the years, corrected curve lenses matured into a stable and somewhat unchanging industry. But a significant improvement did occur during the 1960s, when lens companies transitioned their lens portfolios from plus-cylinder form to minus-cylinder form. But it wasn’t until the arrival of freeform technology, first via Seiko’s groundbreaking patent in 1987 and later through Carl Zeiss’ success in making freeform technology production friendly, that spectacle lens design finally surpassed the standard set by of the 1912 Zeiss Punktal lens.

ENTER ELECTRONIC LENS ORDERING

As the optical industry entered the new millennium, freeform manufacturing and digitally optimized lens design came into their stride. Progressive lenses became ever more user-friendly, with improved reading utility and far less optical compromise tied to the need to blend the gradient of progressive umbilic into the rest of the lens surface. With the ability to enter custom position of wear measurements, more progressive wearers could enjoy the benefits of “20/Happy.” But despite 60 years elapsing since its arrival, the boxing method of A, B and DBL frame measurements remains the go-to system most eyecare professionals use for their spectacle orders. With the advent of electronic lens ordering in the new millennium, eyecare professionals finally have the proper tool to move their spectacle ordering process into the 21st century.

EARLY PORTAL TECHNOLOGY

TIn the early 2000s, internet speeds finally became fast enough to allow duplex communication in lens ordering. Here, hierarchal lens parameter choices are communicated to a remote server, which then serves a tailored “next up” list of options based on the selections already made. The challenge for portals has been keeping the catalog of new products current. As new products enter the market, they are to be added to the portal which further compounds the challenge of scrolling through an endless list of choices. This situation is ripe for creating operator fatigue and order-entry errors. Further, early lens ordering portals often required an engineering degree to connect a tracer for uploading a job’s frame tracing. All of this sets the stage for a better lens ordering system.

THE IDEAL ORDERING PORTAL

Let’s see what a wish list for an ideal portal might look like:

1. User-friendly interface—one that handles orders from finished stock lenses to the most sophisticated and advanced freeform and personalized progressives.

2. Freedom to personalize—portal access restrictions for qualified staffers, with record keeping that tracks the orders an individual staffer has placed.

3. Easy tracer configuration—connecting your tracer to upload frame tracings should be a plug-and-play affair.

4. 3D visualization—after order entry, a way to view what the finished lens would look like in three dimensions.

5. Human-factor friendliness—reality check: People make mistakes. A contemporary order system should strive to reduce errors rather than facilitate them. No one wants their jobs to end up in the lab’s callback or redo stack.

6. Order history, status and delivery tracking—the ability to quickly access order history is essential, especially when a job is delayed because a redo was required. In addition, a necessary part of customer service is the ability to accurately forecast when a pair of glasses will be ready for customer delivery—without the need to contact the lab or wait for a callback.

7. Ongoing portal improvement—nothing is more discouraging than portal updates encountering unexpected delays. Improvements should arrive as a surprise rather than the feeling “it’s about time.”

SPECTACLE ORDERING AT ITS FINEST

In today’s age of sophisticated freeform lenses, having a portal with advanced personalization capabilities and job rendering is as essential to consumer satisfaction as providing authoritative lens, frame fit and styling advice. A robust and easy-to-use ordering portal is clearly a welcome addition to any practice. And while online companies crunch pools of big data to promise “good enough” measurements, brick-and-mortar opticals have to fully commit to delivering the highest levels of visual and business excellence to remain competitive. If you pride yourself on providing the full value for every dollar your patients spend, you must leave behind phone, fax and the comfort of the boxing system and start using all the power that resides in today’s advanced spectacle ordering portals.

USING ZEISS VISUSTORE

The Zeiss Visustore is one of the latest entries available for helping ECPs surmount contemporary spectacle order challenges. Let’s look at Visustore’s highlights:

- Order accuracy—Visustore has native intelligence built into its back end so that the latest lens and treatment choices are immediately available to order. A big bonus with Visustore is it’s impossible to place an order with incompatible elements or create an order that can’t be made.

- Lens selection filtering—Visustore supplies a filter-tree option, which lets the operator narrow the lens and treatment selection process by checking off material, design, color, photochromic or blue filter properties, etc. As one checks off the appropriate boxes, a side panel opens and shows all the filtered choices that meet the selection criterion, eliminating the endless scrolling through unwanted choices.

- Efficiency—unlike other portals, your order entry in Visustore is communicated directly into the Zeiss LMS, so there are no delays because of a need for file conversion.

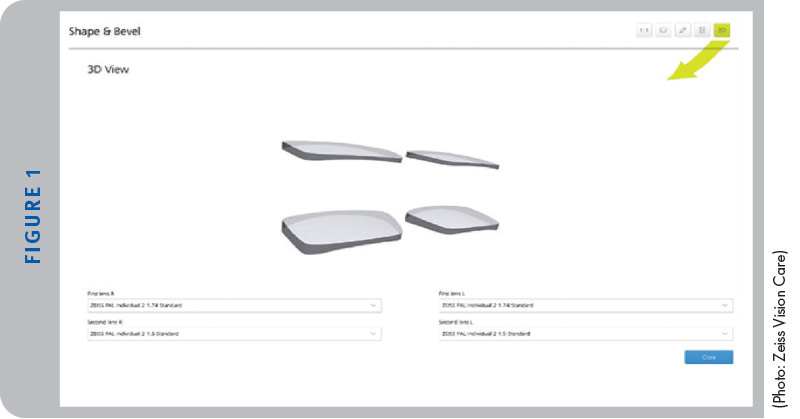

- Visualization—after communicating with the Zeiss server, Visustore offers several unique

visualization tools:

- “Actual size” lens representation, including the ability to properly calibrate the operator’s display.

- 3D visualization includes rotating the lens rendering to observe a finished pair of lenses in three dimensions.

- Comparing different lens materials—3D rendering of two pairs of lenses makes it easy to compare lens thicknesses and curves using a material, base curve or refractive index.

- Advanced corridor simulation—using information optimized after lens design system calculations, Visustore can display the location of the near add power. The user can choose different “frame fit” or corridor values, and Visustore will quickly illustrate the new position of the 100 percent add power reading point. The optician can see where the revised reading points lie within the chosen frame shape.

- Base curve selection—One of Visustore’s best features is its ability to request a base curve and see if that choice is available for the specific lens design and material index choice. If not, theVisustore Calc Engine will supply the next closest curve acceptable to the LMS. If you provide uploaded tracings, Visustore’s default base curve will be the closest to the frame’s eye wire curve.

- Connectivity—Visustore connects directly to the customer’s Zeiss account dashboard to review current order status and shipment tracking information.

- Easy tracer configuration—plug-and-play tracer setup.

- Practice personalization—individual employee setup and searchable records, including stock

lens orders, along with order-specific value configurations:

- Choice of Plus/minus cylinder convention.

- Automatic preference for edge polish.

- Preference settings for input, including diopter precision, alerts for right/left value duplication and the ability to simultaneously review both polar and X-Y prism notations.

- Visustore interfaces with most practice management systems.

- Commitment to ongoing development—Zeiss is committed to the continuing development of Visustore and places high value on all user input toward improvement.

- Special bonus features—there are many hidden nuggets in Visustore. One of my favorites is helpful for accounts that primarily edge uncut lenses. Visustore can display the appropriately modified blocking values for PD and height in a progressive order with a prism. Many often overlook this area, but it ensures the progressive corridor is optimally aligned when prescribed prism is present.

–BS

Contributing editor Barry Santini is a New York State licensed optician and contact lens fitter with Long Island Opticians in Seaford, N.Y.