“We’re not normal,” declares Oakley CEO Colin Baden, describing the company to a small gathering of journalists who have flown in from all corners of the globe for an exclusive behind-the-scenes tour of Oakley’s headquarters. “We’ve been around for 35 years, but you won’t see any anniversary logos on or products. We’re a forward-looking company.”

“We’re not normal,” declares Oakley CEO Colin Baden, describing the company to a small gathering of journalists who have flown in from all corners of the globe for an exclusive behind-the-scenes tour of Oakley’s headquarters. “We’ve been around for 35 years, but you won’t see any anniversary logos on or products. We’re a forward-looking company.”

Oakley’s past speaks for itself, as the company has long prided itself on innovative advances in sportswear and likes to keep its offices under wraps for obvious security reasons. However, to commemorate the launch of the high-end Elite Collection, 20/20 was invited as part of a select group of “elite” journalists to get a sneak peek at what happens behind the walls of the eyewear giant. From the (drivable) Army tank out front to the WWII airplane ejection seats in the lobby to the eyewear design, assembly and testing areas, Oakley’s facilities are anything but typical.

After the tour, the Elite Collection was finally unveiled—three new sunglasses, a wristwatch and a military boot made from high-end materials with the best quality and performance in mind. The jewel of the collection, the C Six, is a $4,000 sunglass made entirely from drilled carbon fiber.

“We try to elevate physics to an art form,” says Scott Bowers, Oakley’s senior vice president for global marketing and brand development, explaining what internal pillars guide the company. “We create inventions from scratch and wrap them in art.”

And with 35 years of practice, this brand has distinguished itself as one of the eyewear elite.

—Lauren Taylor

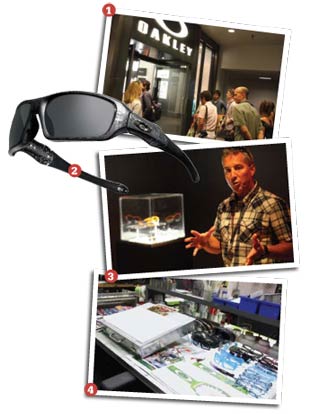

1. Oakley’s on site retailing “test” store

2. The Carbonfiber Elite

3. Scott Bowers, SVP of Global Marketing and Brand Development

4. A peek at frame “painting” in progress

5. Russ Ortiz, VP of Global Brand Communication

6. and 7. Oakley’s Kent Lane acts as guide and explains the blindfold tour procedure

8. Colin Baden, CEO

2. The Carbonfiber Elite

3. Scott Bowers, SVP of Global Marketing and Brand Development

4. A peek at frame “painting” in progress

5. Russ Ortiz, VP of Global Brand Communication

6. and 7. Oakley’s Kent Lane acts as guide and explains the blindfold tour procedure

8. Colin Baden, CEO