TEAMING LENS SCIENCE WITH LEN S FASHION

ZEISS PhotoFusion Now Introduced in Trivex Lens Material

By Linda Conlin, ABOC, NCLEC

Release Date: January 1, 2022

Expiration Date: December 31, 2022

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Describe the development and latest patented photoactive molecules behind ZEISS PhotoFusion lens technology.

- List the vision and eye protection benefits when wearing ZEISS PhotoFusion photo-activated lenses.

- Explain the fashion and eye protection benefits when teaming ZEISS DuraVision flash mirrors with ZEISS PhotoFusion technology in high-performance lens monomers such as PPG TRIVEX MATERIAL®.

To Earn Continuing Education Credit:

This course has been approved for one (1) hour of Ophthalmic Level II continuing education credit by the ABO. Course Number: STWJHI044-2

This course is approved for one 1 hour O.D. CE credit by NYSSO

Support:

This is a product spotlight CE supported by an educational grant from ZEISS

Photochromic lenses, also know as self-tinting lenses, automatically increase or decrease light transmittance in response to the level of UV radiation exposure. The photoreactive lens category continually improves with technology. Activation and deactivation speed and indoor clarity dramatically improve as scientific breakthroughs make the latest iterations better than ever. The impetus for improvement is consumerdriven demand. Consumers identified faster reaction speeds, clarity and photochromic longevity as key lens performance features desired in their light-responsive lenses.

ZEISS PhotoFusion self-tinting lens technology utilizes patented photoactive molecules that deliver more of what the consumer wants: faster darkening and faster fade back speed. Complementing this enhanced light-reactive performance are fashion options, including a wide portfolio of colors, flash mirrors, and materials that now include the clarity, thinness and strength of Trivex Lens material. ZEISS PhotoFusion, ups the photochromic “cool factor” by offering lenses with fashion tints and flash mirror coatings, making this a high style fun lens option for those who want both fashion and performance in their eyewear. In this course, you will learn about ZEISS PhotoFusion photochromic lenses and ZEISS DuraVision flash mirror coatings that transform the practical and functional photochromic lens into a standout fashion accessory.

Why is the fashion factor so important? As ECPs,

we recommend products based on useful features, but we get ahead of ourselves because the

consumer is not interested in rational reasons

until they buy in emotionally. Behavioral science has shown that emotional response heavily

influences purchasing decisions. Emotion is

vital for all decision making as evidenced in

studies by Marsel Mesulam, Lennart Heimer and

Mortimer MishkinDamasio, which showed

that “patients with damage to the part of the

prefrontal cortex that processes emotions often

struggle with making even routine decisions.”

The response is less about the physical product

and more about how that product will make

their life better, cooler, more fun and more fulfilling. For this reason, appealing to their desire

to be fashionable while having fun in their

“cool” high-tech lenses will elicit an emotional response and purchase commitment. Although

our purchase decisions rely on emotion, we

need to rationalize our decision in our postpurchase process. So be prepared to WOW

them with all the great reasons their decision

was wise and give them the benefits of the

product features.

Why is the fashion factor so important? As ECPs,

we recommend products based on useful features, but we get ahead of ourselves because the

consumer is not interested in rational reasons

until they buy in emotionally. Behavioral science has shown that emotional response heavily

influences purchasing decisions. Emotion is

vital for all decision making as evidenced in

studies by Marsel Mesulam, Lennart Heimer and

Mortimer MishkinDamasio, which showed

that “patients with damage to the part of the

prefrontal cortex that processes emotions often

struggle with making even routine decisions.”

The response is less about the physical product

and more about how that product will make

their life better, cooler, more fun and more fulfilling. For this reason, appealing to their desire

to be fashionable while having fun in their

“cool” high-tech lenses will elicit an emotional response and purchase commitment. Although

our purchase decisions rely on emotion, we

need to rationalize our decision in our postpurchase process. So be prepared to WOW

them with all the great reasons their decision

was wise and give them the benefits of the

product features.

YESTERDAY’S TECHNOLOGY

Photochromic lenses have come a long way from their origins when William Armistead made a yellow opal glass lens containing silver halide that caused the lens to darken in sunlight. His technology was patented for photochromic spectacle lenses in 1962. Some of us can recall those early lenses. They were slow to darken and even slower to lighten, never becoming completely clear indoors. They were very temperature sensitive and darkened less in hot temperatures and more in cold temperatures. True to their nature, past photochromic lens technologies took longer to return to clear in cold temperatures and did not get as dark in hot temperatures. Lenses made with old photochromic lens technology fatigued over time resulting in an overall performance decline and lenses with a permanent yellowish cast. Tempering could be done only by chemical methods due to the adverse effects on photosensitivity from heat treating the lenses. Because of the silver halide distribution throughout the lens material, thinner parts of the lenses were lighter where there was less silver halide, and thicker parts were darker, where there was more. That meant that minus lenses were less tinted in the center, while plus power lenses were lighter at the edges, making early photochromic lenses a poor choice for higher power prescriptions.

The shortcomings of old technology provided the impetus for new research and progress. In 1983, American Optical, which became Carl Zeiss Vision in 2005, developed Photolite, the first plastic photochromic lens. The photochromic properties were the result of a combination of organic photochromic pigments stabilized with a protective inorganic coating. The pigments were imbued into the lens material resulting in an even coloration. The first Photolite lenses were blue when darkened. Still, because they were plastic, they could be tinted in various colors, including gradients, to mitigate the blue darkened color while providing fashionable indoor tints. Unfortunately, these lenses had a lifetime performance expectancy of about two years before fatiguing.

TODAY’S TECHNOLOGY

In the more than 35 years since the debut of

Photolite, innovation has continued to

improve photochromic plastics, resulting in

greater thermal stability, that is, less temperature dependence, greater variation between the

clear and darkened states, and faster reactivity,

as well as more color and material choices. The

new lenses work using leuco dyes in which

molecules can switch between two chemical

forms or isomers, one of which is colorless and

the other form darker, depending on the relative balance between thermal and ultraviolet

radiation. The darkened state, called activated,

occurs upon exposure to UV radiation in sunlight, absorbing visible light. In the absence of

UV, the molecules return to their colorless or

ground state as indoors.

In the more than 35 years since the debut of

Photolite, innovation has continued to

improve photochromic plastics, resulting in

greater thermal stability, that is, less temperature dependence, greater variation between the

clear and darkened states, and faster reactivity,

as well as more color and material choices. The

new lenses work using leuco dyes in which

molecules can switch between two chemical

forms or isomers, one of which is colorless and

the other form darker, depending on the relative balance between thermal and ultraviolet

radiation. The darkened state, called activated,

occurs upon exposure to UV radiation in sunlight, absorbing visible light. In the absence of

UV, the molecules return to their colorless or

ground state as indoors.

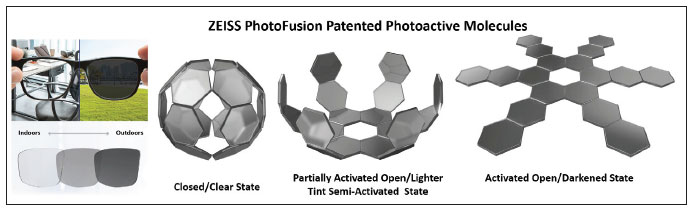

ZEISS PhotoFusion lenses activate with less UV radiation exposure, allowing them to darken quicker outdoors, about 20 percent faster than previous ZEISS photochromic lens technology. Because there is a lower accumulation of UV energy in the darkening phase, the lenses fade to clear up to twice as fast as previous ZEISS photochromic technology. (Activation and fade back times, as stated earlier, are dependent on temperature, UV exposure and lens material.) How do they work? To produce a ZEISS self-tinting lens involves incorporating millions of tiny patented photoactive light-sensitive molecules measuring only 0.3 nm (0.0000003 mm) in size into a coating that is bonded to the lens at a thickness of only 0.05 millimeters. When exposed to UV radiation, the photoreactive molecules reconfigure, opening the molecular rings. The molecules rotate and take on a new form that darkens and absorbs visible light (the activated state). When UV exposure is reduced, the molecular bonds return to their ground state configuration, the rings close, and the molecules rotate back to their clear state arrangement. ZEISS PhotoFusion lenses have a high quantum yield allowing them to change the chemical configuration of their novel photoactive molecules quickly in the presence or absence of ultraviolet irradiation for rapid conversion between the activated (dark) state and the ground (clear) state. Quantum yield measures the efficiency of the photochromic change relative to the level of UV radiation absorption. ZEISS PhotoFusion photochromic lenses have an exceptionally high quantum yield and therefore require less ultraviolet radiation to activate and darken.

I’ve described the photochromic change from light to dark and back again, but how can it happen faster? As stated above, the photoreactive molecule rings not only open and close but also change form. The molecules need sufficient space to perform those molecular acrobatics. ZEISS PhotoFusion lenses utilize a larger, more open polymer matrix or molecular environment, which allows the molecules to change form and reorient more quickly, especially from the activated to the ground state. In old photochromic technologies, the molecular environment was much tighter, causing the molecules to take longer to change and reorient, slowing the photochromic change, particularly when fading to clear.

Fully activated ZEISS PhotoFusion lenses quickly darken to only 11 percent visible light transmission, while in the fully clear state allows 93 percent visible light transmission, making the lenses fine for night driving. New Extra Grey lenses range from 8 percent transmission when fully activated to 91 percent transmission in the full ground state. All PhotoFusion lenses satisfy the ISO 8980-3 requirements for dark (Category 3) lenses at 73.4 degrees Fahrenheit (23 degrees Celsius).

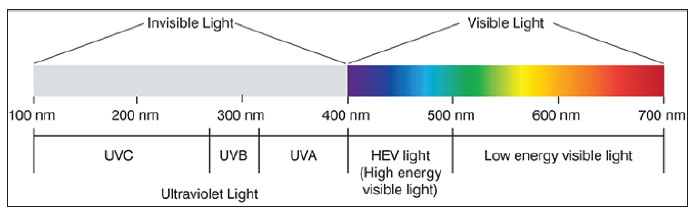

SUN PROTECTION

The energy of electromagnetic radiation increases as the wavelength decreases. So UV radiation below 380 nanometers (nm) has a higher capacity to disrupt cellular function than visible light between 380 nm and 760 nm. We know that bright sunlight and glare can cause ocular discomfort, squinting, reduced acuity and eyestrain in the short term. Longer exposure times can delay and slow the dark adaptation process, which negatively affects night vision, and excessive glare can impair visual function completely. Photokeratitis, effectively a sunburn of the cornea, can occur in a relatively short period of intense UV exposure, including reflected sunlight from sand, water, ice and snow. Long-term exposure to UV radiation increases the risk of cataracts and macular degeneration. ZEISS PhotoFusion lenses offer excellent protection from this harmful radiation by blocking 100 percent of UVA (315 nm to 380 nm) and UVB radiation (280 nm to 315 nm) up to 400 nm. That goes beyond the current American National Standards Institute/International

Organization for Standardization (ANSI/ISO)

guideline of 380 nm for a material to meet their

definition of 100 percent UV protection in a

lens. UV protection up to 400 nm fills a critical

exposure gap.

Organization for Standardization (ANSI/ISO)

guideline of 380 nm for a material to meet their

definition of 100 percent UV protection in a

lens. UV protection up to 400 nm fills a critical

exposure gap.

The cumulative risk to the eye from indoor blue light exposure is still under review. Still, studies have shown that chronic exposure to outdoor levels of blue light may increase the risk of age-related macular degeneration (ARMD). Chronic exposure to ultraviolet and short-wavelength visible radiation may impact the function of photoreceptors and the retinal pigment epithelium, causing photochemical damage. As more information is presented, many eyecare practitioners (ECPs) want to offer their patients protection against potential cumulative damage from long-term exposure to both outdoor and indoor levels of blue light, and informed consumers want that protection too. According to the Essilor method, ZEISS PhotoFusion lenses provide UV protection up to 400 nm and achieve up to 22 percent indoor ISO blue light protection and up to 27 percent indoor blue light protection. According to ZEISS, no leading photochromic has more indoor blue light protection than ZEISS PhotoFusion (1.5 material in grey, the most popular color among photochromics, measured at 23 degrees Celsius).

COLOR AND PERFORMANCE

The leuco dyes mentioned previously contain

chromophores, which are the chemicals that

produce colors by absorbing visible light when

exposed to ultraviolet radiation. Each chromophore has a distinct absorption spectrum

when exposed to UV radiation, resulting in a

specific color. Two or more chromophores may

be used to achieve a particular color, but different chromophores may respond differently

to temperature, resulting in variations from the

desired color. The patented chromophores

used in ZEISS PhotoFusion lenses have broad

absorption spectra that allow for excellent

color control. This results in superior color

stability with minimal color variation when

activated and the flexibility to offer more color

choices. The difference in spectral transmittance causes visible differences in lens colors

for longer than 500 nm. High energy visible

light is considered to be the shorter wavelengths below 500 nm. All color choices provide excellent UV and blue light protection.

The leuco dyes mentioned previously contain

chromophores, which are the chemicals that

produce colors by absorbing visible light when

exposed to ultraviolet radiation. Each chromophore has a distinct absorption spectrum

when exposed to UV radiation, resulting in a

specific color. Two or more chromophores may

be used to achieve a particular color, but different chromophores may respond differently

to temperature, resulting in variations from the

desired color. The patented chromophores

used in ZEISS PhotoFusion lenses have broad

absorption spectra that allow for excellent

color control. This results in superior color

stability with minimal color variation when

activated and the flexibility to offer more color

choices. The difference in spectral transmittance causes visible differences in lens colors

for longer than 500 nm. High energy visible

light is considered to be the shorter wavelengths below 500 nm. All color choices provide excellent UV and blue light protection.

Like all organic dyes, photochromic leuco

dyes are susceptible to degradation by oxygen

and free radicals after continual exposure to

UV radiation and environmental elements.

Over time, photochromic plastics show a

reduction in the range between the activated

and ground states, resulting from photo-oxidation from exposure to UV radiation. What’s

more, as the chromophores deteriorate, they

lose transparency indoors and discolor, a state

known as fatigue. Photochromic fatigue can

be reduced by adding a UV stabilizer or providing a barrier to oxygen and other chemicals.

This will prolong the expected period of excellent photochromic performance. ZEISS uses

chemical additives in the PhotoFusion polymer matrix that inhibit polymer degradation.

These stabilizers act like the antioxidants we

take for our bodies to slow down photochemical degradation reactions. This results in less

discoloration and loss of transparency in the

clear state after prolonged exposure to UV

radiation compared to previous ZEISS photochromic lenses, thus providing wearers with higher performance and value.

Like all organic dyes, photochromic leuco

dyes are susceptible to degradation by oxygen

and free radicals after continual exposure to

UV radiation and environmental elements.

Over time, photochromic plastics show a

reduction in the range between the activated

and ground states, resulting from photo-oxidation from exposure to UV radiation. What’s

more, as the chromophores deteriorate, they

lose transparency indoors and discolor, a state

known as fatigue. Photochromic fatigue can

be reduced by adding a UV stabilizer or providing a barrier to oxygen and other chemicals.

This will prolong the expected period of excellent photochromic performance. ZEISS uses

chemical additives in the PhotoFusion polymer matrix that inhibit polymer degradation.

These stabilizers act like the antioxidants we

take for our bodies to slow down photochemical degradation reactions. This results in less

discoloration and loss of transparency in the

clear state after prolonged exposure to UV

radiation compared to previous ZEISS photochromic lenses, thus providing wearers with higher performance and value.

ZEISS PhotoFusion lenses come in seven great colors: Grey, the worldwide-preferred color for self-tinting lenses; Brown for enhanced contrast and reduced glare; Extra Grey that is extra dark even in warm climates; Pioneer Green, a classic grey-green when activated; Pro Brown and Pro Grey for faster activating and clearing; and Blue, an exciting new fun and fashionable color choice. Every choice benefits the wearer with durability, color consistency, UV protection, outdoor blue light protection and twice the indoor blue light protection as standard clear lenses. ZEISS PhotoFusion lenses are available in most ZEISS lens styles, progressives, bifocals, trifocals and single vision.

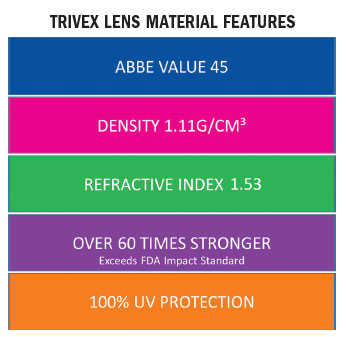

Material matters: ZEISS PhotoFusion lenses

are available in polycarbonate, 1.50, 1.60 and 1.67 index materials. And now ZEISS PhotoFusion is available in Trivex Lens Material. Trivex lens monomers were initially developed for use in helicopter windshields and

fighter jet canopies for the military. Trivex is

an ultra-lightweight, advanced polymer technology with extreme impact resistance and optical purity. With more than a decade of development for military use, the technology was

subjected to rigorous ballistic and extreme

performance testing. Trivex is made possible

through complex chemistry and advanced

production methods. Trivex material is a

urethane-based pre-polymer that PPG developed and refined for use as an ophthalmic

lens material. Trivex is a unique lens material

with an entirely new molecular structure built

on polyurethane chemistry, similar to many

optical lens materials. But PPG chemists found

a way to enhance the base polyurethane molecule by enriching it with additional nitrogen.

The result is a lens material that is not only optically superior but also exceptionally strong

and ultra-lightweight.

Material matters: ZEISS PhotoFusion lenses

are available in polycarbonate, 1.50, 1.60 and 1.67 index materials. And now ZEISS PhotoFusion is available in Trivex Lens Material. Trivex lens monomers were initially developed for use in helicopter windshields and

fighter jet canopies for the military. Trivex is

an ultra-lightweight, advanced polymer technology with extreme impact resistance and optical purity. With more than a decade of development for military use, the technology was

subjected to rigorous ballistic and extreme

performance testing. Trivex is made possible

through complex chemistry and advanced

production methods. Trivex material is a

urethane-based pre-polymer that PPG developed and refined for use as an ophthalmic

lens material. Trivex is a unique lens material

with an entirely new molecular structure built

on polyurethane chemistry, similar to many

optical lens materials. But PPG chemists found

a way to enhance the base polyurethane molecule by enriching it with additional nitrogen.

The result is a lens material that is not only optically superior but also exceptionally strong

and ultra-lightweight.

• In thermoplastics, the chains are independent of each other and can flow freely to

be reformed.

• In thermosets, “cross-links” are created during polymerization resulting in a complex

interconnected and permanent network.

Trivex lens material is the first optical lens material to combine the best features of thermoplastics and thermosets into one unique material. Lenses made from Trivex material are cast in molds using a special machine and thermally cured. The tri-performance properties of the material provide for crisp and clear, strong and safe, light and thin lenses.

WINNING COMBINATIONS

In 1935, Carl Zeiss patented their first antireflective coating (AR). The company today is an industry leader in performance coating technology. Anti-reflective coating reduces the undesired reflected light from the surface of the lenses. It eliminates ghost images caused by internal lens reflections that could affect the visual quality required for relaxed, comfortable vision. ZEISS now offers an array of coatings to pair with ZEISS PhotoFusion lenses. For example, ZEISS DuraVision Platinum and ZEISS DuraVision Silver, two ZEISS premium coatings, use an integrated system of coating layers, densely packed using ion-assisted deposition (ion bombardment) to yield a lens surface that is three times harder than the previous generation of hard antireflective coated ZEISS lenses. The coating is strong, dirt-resistant and easy to clean.

Conventional AR coatings produce maximum residual reflectance near the peak sensitivity of the eye, reducing their effectiveness. The maximum residual reflection of DuraVision premium coatings has been shifted to the blue end of the spectrum for reduced residual reflectance visibility. But it doesn’t stop there. While more than 90 percent of UV radiation comes directly from the front, a small part approaches the eye indirectly from the sides and back. As some UV rays may be reflected onto the eye by the back surface of the lens, ZEISS anti-reflective coatings are designed to have low reflectance in the UV spectral range. The back surface UV protection is integrated as a standard feature into all premium ZEISS DuraVision coatings. These coatings deliver what our patients want: Clearer and more comfortable vision thanks to increased light transmittance and greater lens clarity, a better appearance due to reduced reflections and superior hardness for durable, anti-static, easy-to-clean, scratch-resistant lenses.

FUNCTION MEETS FASHION

Patients can now customize their ZEISS PhotoFusion, tinted, polarized or even clear lenses

with a new array of mirror and flash mirror

coatings. That lets your patients cultivate their

very own unique look—and they get the

added benefits of on-trend fashion in a highperformance and convenient photochromic

lens. ZEISS PhotoFusion and sunglass lenses

with ZEISS DuraVision Flash Mirror coatings reduce light transmission and glare,

improving visual comfort, both in extreme

light conditions, such as in the mountains or

the snow, and on the beach, in the park, or

when you’re shopping or playing sports.

While full and flash mirrors are an excellent

add-on for sunglasses that increase the coolfactor and the function-factor, new flash mirrors

take photochromic fashion mirrors to a whole

new level.

Patients can now customize their ZEISS PhotoFusion, tinted, polarized or even clear lenses

with a new array of mirror and flash mirror

coatings. That lets your patients cultivate their

very own unique look—and they get the

added benefits of on-trend fashion in a highperformance and convenient photochromic

lens. ZEISS PhotoFusion and sunglass lenses

with ZEISS DuraVision Flash Mirror coatings reduce light transmission and glare,

improving visual comfort, both in extreme

light conditions, such as in the mountains or

the snow, and on the beach, in the park, or

when you’re shopping or playing sports.

While full and flash mirrors are an excellent

add-on for sunglasses that increase the coolfactor and the function-factor, new flash mirrors

take photochromic fashion mirrors to a whole

new level.

ZEISS DuraVision Flash Mirrors come in five great options: White, Jade, Sapphire, Ruby and Amber. And in case you haven’t heard the chatter, photochromic lenses with a fashion flash mirror are opening up a whole new fashion market for photochromic. Combine this fashion trend with the state-of-the-art photochromic lens performance of ZEISS PhotoFusion, and it’s a win-win for fashion and function.

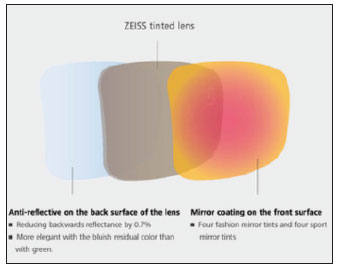

Cheap sunglasses use cheap flash mirror coatings that scratch and peel off easily, and your patient may have had a bad experience with mirrors in the past. But now you can WOW your patients by offering them the best of both worlds: a cool mirrored lens in fun fashion or sporty colors and the best ZEISS optics. These new flash mirrors have a lower reflectance than standard mirrors. Because backside AR is important to have on mirrors to reduce the reflections from the back of the lens bouncing into the eye, all ZEISS DuraVision Flash Mirrors and standard mirrors come with their flagship backside AR ZEISS DuraVision Sun. This will improve visual comfort in extreme light conditions outdoors or indoors on a self-tinting lens.

WHAT WEARERS WANT

Photochromic wearers want fast performance.

Fast to react to UV and darken, fast to return to

clear indoors and return to a truly clear lens

without residual color indoors.

Photochromic wearers want fast performance.

Fast to react to UV and darken, fast to return to

clear indoors and return to a truly clear lens

without residual color indoors.

Photochromic lenses may not be suitable for every situation. For example, automobile windshields block some of the UV needed for photochromic lenses to reach their fully activated state. For driving, a quality pair of polarized sunglasses may be preferred to reduce the light intensity reaching the eye and to minimize blinding reflected glare, as only polarized lenses can do. Polarized sunglasses are also recommended in environments with intense reflected glare from surfaces such as water or snow. With those exceptions, many eyeglass wearers benefit from the convenience of one pair of eyewear that: 1. Corrects their vision, and 2. Conveniently protects their eyes from harmful solar radiation outdoors.

Can you think of anyone who might benefit from the acuity, sun protection and convenience of photochromic? Photochromic lenses are perfect for kids. Kids struggle to keep track of their stuff, so multiple pairs of eyewear and sunglasses are too much for them to handle. They need the correction, and they need protection; in fact, their eyes are more vulnerable to sun damage than an adult eye, and yet only 7.6 percent of parents report that their children wear sunglasses all the time when outdoors. Many of us are outdoors for extended periods without our sunglasses, as reported by Vision Watch, making photochromic eyewear the perfect choice for our general-purpose pair of eyewear.

When we have photochromic lenses in our glasses, our eyes are never without sun protection outdoors. Eyeglass wearers can be exposed to illumination levels that vary during the day from as high as 100,000 lux (a measure of the intensity, as perceived by the human eye, of light that hits or passes through a surface) in direct sunlight to less than 10 lux in a dimly lit room—a range of 10,000 to 1! Patients who are light-sensitive or who spend the majority of their day going from outdoors to indoors and back again, such as salespeople or real estate agents, will enjoy the convenience of the fast reaction in the ZEISS PhotoFusion photochromic lenses. Be sure that your lens recommendations consider those clues uncovered from targeted lifestyle questions. A pair of glasses that self-tints in response to changes in ambient light levels provide the convenience many people want while still enjoying great vision in stylish eyewear.

Here is what wearers demand in a photochromic lens: Quick change from light to dark and back again; lenses that are very dark in bright light but clear indoors; 100 percent UV protection, lightweight and impact-resistant, durability, longevity and high performance. Now, for what they want (desire), fashion and style, and features that enhance their lifestyle. ZEISS PhotoFusion lenses with fashion tints and DuraVision premium AR and flash mirror coatings, plus the new ultra-lightweight Trivex material, check all the boxes of the consumer wish list, thus enabling the ECP to recommend these products with confidence. Be sure to present these benefits to your patients when you discuss lens recommendations.

CONCLUSION

New technologies have produced lenses engineered with significant improvements over previous photochromic lenses. Poorly performing photochromic glass lenses of the past have progressed to high-performance, fashionable, protective and safe lenses in various lens styles, colors, materials and enhancements. ZEISS PhotoFusion lenses activate and deactivate more quickly, providing exceptional protection from harmful solar radiation up to 400 nm, blue filtering, and they have excellent color stability, with minimal performance loss over time. Importantly they rapidly return to clear indoors, fulfilling a big ask by the consumer. ZEISS PhotoFusion lens options meet the ECP’s need to provide quality vision and protection while satisfying the consumer’s need to be stylish and comfortable.