EYEGLASS DISINFECTION – SAFE, EFFECTIVE AND FAST

Introducing ZEISS UVClean

By Linda Conlin, ABOC, NCLEC

Release Date: November 1, 2020

Expiration Date: December 31, 2022

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Learn more about UV on the electromagnetic spectrum.

- Learn more about the germicidal properties of UVC.

- Learn more about ZEISS UVClean technology for frame disinfection.

Credit Statement:

This course has been approved for one (1) hour of Ophthalmic Level I continuing education credit by the ABO. To earn ABO credit, please review the questions and take the test at 2020mag.com/ce. Note: As of January 2020, no tests will be graded manually. Please call (800) 825-4696 for more information.

This course is approved for one 1 hour O.D. CE credit by NYSSO

THIS COURSE IS SUPPORTED BY AN EDUCATIONAL GRANT FROM ZEISS

INTRODUCTION

That patient just tried on 10 frames, but who’s

counting? There’s a sale pending, maybe two

pairs. But the person who has to clean them is

thinking, “Oh, Jimminy, not again.”

He/she is not alone. It’s the new burden for

eyecare professionals across the country. With

the rapid, silent and deadly spread of the coronavirus, eyecare professionals have put into effect

more intensive hygiene protocols to protect their

patients and their staff. This necessary effort,

however, comes at a cost. It takes time. It takes

labor. It stretches the limits of what staff must

do in order to serve the same number of

patients. At the same time, many practices have

downsized, meaning they already are dealing

with less manpower before things like additional

hygiene are considered.

There are new frame disinfection protocols.

Not only do they consume staff time, they are

cumbersome when in addition to cleaning

instruments and surfaces, frames must be

cleaned between patients as well, using liquids

and chemicals to wash by hand every frame a

patient has tried on. In other words, that invasive microbe has driven up operating costs for

eyecare professionals. Naturally, individuals

have searched for a way of mitigating those

costs while protecting staff and patients. They

have turned to a long established standby:

UVC. That beam of light, which we all have

learned is harmful to humans, also destroys a

variety of microbes. It is dangerous, so the

device used for UVC disinfection must be properly constructed to contain it and make it safe

for the user. But it’s proven and effective. Let’s

see how.

That patient just tried on 10 frames, but who’s

counting? There’s a sale pending, maybe two

pairs. But the person who has to clean them is

thinking, “Oh, Jimminy, not again.”

He/she is not alone. It’s the new burden for

eyecare professionals across the country. With

the rapid, silent and deadly spread of the coronavirus, eyecare professionals have put into effect

more intensive hygiene protocols to protect their

patients and their staff. This necessary effort,

however, comes at a cost. It takes time. It takes

labor. It stretches the limits of what staff must

do in order to serve the same number of

patients. At the same time, many practices have

downsized, meaning they already are dealing

with less manpower before things like additional

hygiene are considered.

There are new frame disinfection protocols.

Not only do they consume staff time, they are

cumbersome when in addition to cleaning

instruments and surfaces, frames must be

cleaned between patients as well, using liquids

and chemicals to wash by hand every frame a

patient has tried on. In other words, that invasive microbe has driven up operating costs for

eyecare professionals. Naturally, individuals

have searched for a way of mitigating those

costs while protecting staff and patients. They

have turned to a long established standby:

UVC. That beam of light, which we all have

learned is harmful to humans, also destroys a

variety of microbes. It is dangerous, so the

device used for UVC disinfection must be properly constructed to contain it and make it safe

for the user. But it’s proven and effective. Let’s

see how.

UV ON THE ELECTROMAGNETIC SPECTRUM

Our perception of light is odd. We wake up in the middle of the night, and our hand searches for a switch to turn on the light. It’s a thing. We don’t think of it as a wave, much like the ones of the ocean or sound. Light is a combination of waves and particles. It behaves like both. Essentially, light is energy. It’s radiant energy. Its strength and power are measured on the electromagnetic spectrum.

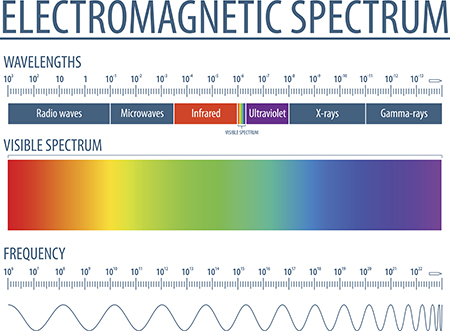

As a refresher, the electromagnetic spectrum is just that, a spectrum. After a light rain in the spring or fall, look out the window, you may see a rainbow. The water vapor in the atmosphere breaks light down into the colors that make up visible light. I have a prism on my desk. When I hold it up to light, it will separate visible light into a spectrum. At the far right of the spectrum, light color transitions to violet. Beyond, light is not visible to the human eye. It’s there, and on the purple side of the spectrum, the invisible light is ultraviolet. It comes in three forms UVA, UVB and UVC, all determined by their wave frequencies (measured in hertz, Hz) and wavelength (nanometers, nm). Here’s a more technical peek at ultraviolet. Let’s get back to the hertz and nanometer. One hertz isn’t what happens after your older brother punches you in the arm. One hertz frequency equals one cycle or complete wave per second. One nanometer is one billionth (10-9) of a meter long. It stands to reason, then, that the shorter the wavelength (nm), the higher the frequency (Hz) and the higher the energy. Conversely, the longer the wavelength, the lower the frequency and the lower the energy. Frequency ranges are divided into bands from low frequency long wavelengths to high frequency short wavelengths, which are the most damaging to living tissue. The bands, from low to high frequency are radio waves, microwaves, infrared, visible light, ultraviolet (UV), X-rays and gamma rays. Ultraviolet bands are further divided into UVA, UVB and UVC, with wavelengths between 100 and 400 nm (Fig. 1). Remember the color bands of light exiting a prism and the violet on the far right. Next to that visible light is UVA radiation (or light). The closest band to visible light, UVA radiation is between 315 and 400 nm and makes up 95 percent of all the UV rays from sunlight that come to the Earth’s surface. UVA penetrates deep into skin and can pass through glass. This is the light that you find emanating from tanning beds and that causes most forms of skin aging, such as those dreadful wrinkles our older types are trying to hide. Not only can UVA light pass through glass, it also penetrates deep into the skin (hence the wrinkles). If we move a tad farther to the right on the spectrum, we will find UVB. Its frequency runs between 280 and 315 nm. Most UVB radiation (again, or light) is absorbed by elements in the atmosphere, such as ozone, water vapor, oxygen and carbon dioxide. These four elements protect us from the harmful effects of UVB. The 10 percent of the UVB that dodges these elements is not kind to human beings. It causes sunburn and plays a significant role in the cause of skin cancers, including malignant melanoma.

FIG. 1

UV radiation is harmful because its higher energy causes ionization. Ionization is the process by which a neutral atom becomes positively or negatively charged by gaining or losing electrons. This affects the chemical properties of atoms, causing them to form or break chemical bonds in ways they otherwise would not. This process damages living tissue like skin and eyes. Both UVA and UVB radiation can have long and short-term negative effects on the eyes and vision. Over a short period of time, UV exposure can result in photoconjuctivitis and photokeratitis, which can be considered as a “sunburn of the eye.” While painful, fortunately these conditions are usually temporary and rarely cause permanent damage to the eyes. Long-term effects of UV exposure, however, include cataracts, eye cancers, pinguecula, pterygium, macular degeneration and damage to the delicate skin around the eyes.

WHAT ABOUT UVC?

UVC radiation is the band between 100 and 280 nm and is completely absorbed by the atmosphere. That’s why there is little concern about it with regard to overall UV protection. UVC wavelengths in the range between 100 to 222 nm are known as Far UV (207 to 222 nm) and Vacuum UV (below 200 nm) because they are completely absorbed by air. Wavelengths between 200 and 280 nm are useful for disinfection, and Far UVC has been shown to be harmless to exposed human tissue, while it is efficient in killing pathogens. One minor problem: There are no natural sources of UVC in these wavelengths. They simply don’t reach the Earth.

UVC radiation on Earth is all human made, coming from lamps, lasers and torches, such as a welding torch. You need to be selective about which UVC is used as a disinfectant. Generally, most industrial UVC frequencies are much more intense than the frequencies of UVC used for disinfecting. This more intense UVC is harmful. It’s the reason welders use protective face coverings with specially designed filtering lenses. UVC is so powerful that industry uses it for top surface curing, which creates a surface hardness that resists abrasion better than traditional polishing.

As you probably imagine, exposure to industrial UVC can cause damage to the eyes in as little as three seconds, and long-term exposure can result in cataracts and retinal damage. Like UVA and UVB, UVC can cause

skin burns and excessive exposure can cause skin cancer. But when you are looking for a disinfectant, you need UVC. We will see how the ionizing properties of less intense UVC have the positive effect of killing viruses and germs safely.

UVC AS A DISINFECTANT

While it may seem new, scientists have studied the use of UV radiation as a bactericidal as far back as the 19th century. For example, there were papers written as early as 1878 that showed the effectiveness of short-wavelength light (now called UV light) for eliminating bacteria. In 1903, Niels Finsen won the Nobel Prize in Medicine for the use of UV against lupus vulgaris and tuberculosis of the skin. It wasn’t until 1905 that scientists identified the actual short-wavelength light that acted as a disinfectant. That was the year German ophthalmologist Ernst Hertel found UVC radiation to be effective in destroying bacteria. It would take slightly less than three decades for science to take it an important step further.

In 1933, William F. Wells, a Harvard University sanitary engineer, presented the idea that various-sized droplets containing infectious organisms are expelled into the air and quickly dried by evaporation after an infectious person coughs or sneezes. In 1935, using UVC radiation and carefully controlled conditions, Wells went on to demonstrate that airborne infectious organisms could be effectively killed in a short period of time. These initial investigations would provide the framework and impetus for infection control by irradiation, and the research continues today. With the rise of antibiotic resistant “superbugs,” we have learned that medicine alone isn’t enough to control disease-causing microbes. UVC can kill virtually any organism, and here’s why. When biological organisms are exposed to UV light in the range of 200 nm to 300 nm, it is absorbed by DNA, RNA and proteins in cells, the core elements of cellular survival. All living organisms store genetic information for replication using DNA and RNA. When UVC is absorbed by DNA or RNA, it causes a “kink” in the DNA or RNA helix strands. With enough of these “kinks,” the DNA replication process is disrupted, and the cell cannot reproduce. When proteins absorb UV, however, it can lead to the rupture of cell walls and death of the organism. While it is not necessary to kill pathogens with UV light, enough UV light to prevent the organism from replicating is effective. If cells cannot replicate, they cannot cause infection. Indermeet Kohli, a physicist who studies photomedicine in dermatology at Henry Ford Hospital in Detroit noted, “The ease of use and the noncontact nature of UVC make it a valuable tool amid the pandemic.” UVC has been shown to be effective against viruses, but it takes the right kind of UV in the right dosage. It’s a complex process best left to experts to design, making at-home UV-light devices unreliable. The devices are ineffective because they use a few LEDs which do not create enough UVC to be harmful to humans or to bacteria and germs. Therefore, they are safe because they are ineffective. At-home devices have lower quality control than those designed for health care facilities and don’t offer the necessary precision to ensure pathogens are eliminated. There are several factors in UVC disinfection including the intensity of the UVC, exposure time, the environment, disinfection in air, water or germicidal chamber, and whether the material is porous or nonporous. Therefore, using just any UV light device for disinfection can be dangerous. As Dr. Jacob Scott, a research physician in the Department of Translational Hematology and Oncology Research at Cleveland Clinic, said, “Having something you think is clean, but it’s not, is worse than something that you know is dirty because it affects your behavior toward that object.”

DISINFECTING FRAMES BY HAND

There are three terms we are hearing frequently these days—disinfecting, sanitizing and sterilizing. The terms mean different things and aren’t interchangeable. To be clear, let’s look at what each means. Disinfecting uses chemicals to kill the germs you are trying to avoid. Sanitizing is the act of cleaning and/or disinfecting to cut the number of germs on a surface or object. And sterilizing uses high temperature/ pressure and chemical processes to destroy living microorganisms. For eyewear, disinfection is the most practical way to kill germs.

We know that masks control person to person virus transmission by blocking droplets expelled during talking, coughing or sneezing, but the virus remains on surfaces and can be transmitted by hand when touched, then a person touches their face or another surface. Due to their close contact with the human skin, nose and mouth, and regular contact with human hands, it is safe to assume that spectacles could potentially carry germs, and therefore require disinfection even if frames were tried on for only a short period of time.

Viruses on different surfaces remain viable for varying amounts of time. According to the CDC, here’s how long coronavirus lasts on some common frame materials.

- Metal: 5 days

- Wood: 4 days

- Plastic: 2 to 3 days

- Stainless steel: 2 to 3 days

- Aluminum: 2 to 8 hours

These numbers underscore the importance of disinfecting every frame patient’s touch, every time.

This is the disinfecting process that some frame manufacturers recommend.

- Put on latex gloves.

- Use hydrogen peroxide wipes, a 50/50 water and 3 percent hydrogen peroxide solution or soap and water on a cleaning cloth to clean every part of the frame. (Don’t forget the nosepads!)

- Dry with a microfiber cloth.

- Dispose of gloves and wipes and machine wash the cleaning cloth.

- Wash hands for 20 seconds after disposing of gloves and wipes.

This process takes about two minutes per frame, excluding washing the cleaning cloth. For the 10 frames the patient tried at the beginning of this article, that’s 20 minutes for one patient! In the interim, other patients have tried on frames, and the disinfection process is backing up, keeping frames off display and temporarily unsaleable.

For some practices, the process became so labor intensive they hired additional staff just to clean frames, an extra operating expense. According to The Balance Careers, the average minimum state wage for the U.S. is nearly $9 per hour. Even hiring a less skilled minimum wage worker adds up when practices need more staff to keep up with frame disinfection. All that is in addition to regular staff cleaning dispensing tables, mirrors, tools and other surfaces patients and staff have been in contact with after every fitting or dispensing.

THERE’S A BETTER WAY WITH ZEISS UVCLEAN

To address the difficulties of disinfecting frames by hand one by one, ZEISS Vision Care US is launching ZEISS UVClean technology, an optometry-specific UVC disinfecting device designed especially for eyecare professionals and developed in conjunction with Voxelight, LLC, a developer of technology-based products that use underexplored properties of light. The ability to disinfect up to 10 frames thoroughly and safely in 40 seconds would be a great work, time and money saver, and ZEISS UVClean does just that. It’s the first UV disinfection technology developed with and for eyecare professionals. ZEISS UVClean was rigorously tested by eyecare professionals on frames, demo lenses, Rx lenses, Rx lens coatings and even frame tags to meet the demands of high-volume eyecare practices, and it’s a benefit to any size practice. Designed with ZEISS quality and precision, this cutting-edge device is fast, safe and effective on both frames and lenses, without scratching or damaging delicate materials. With the coronavirus pandemic, people are revisiting ultraviolet light and its role in zapping viruses and bacteria. Hospitals have utilized UV to cut down on drug-resistant superbugs for years, but its use in more common spaces has recently surged. This practice, called ultraviolet germicidal irradiation (UVGI) is used in a variety of applications, such as food, air and water purification. The Centers for Disease Control states that the inactivation of viruses with UV light has been “demonstrated under controlled conditions in a laboratory.” As we have learned, UVC is absorbed and then deactivates viruses and other pathogens. But what about outside of controlled laboratory conditions such as an optical shop? The ZEISS UVClean unit is designed to safely use UVC from four germicidal bulbs and seals it in the chamber. By using four bulbs, there are no shadows on any part of the frames, so the UVC reaches every surface for total disinfection. The lid also locks automatically to ensure an extra level of user safety. Simply place up to 10 frames in the chamber, close the lid and press a button. There is no timer to set or calibration needed for thorough non-touch disinfection in only 40 seconds. Think about how easy and safe it is to clean eyeglasses without soapy water, expensive smelly chemicals, disposable waste, or re-purposed industrial/consumer UV solutions. Not only is ZEISS UVClean a “green” option because it cleans without chemicals, saves water and eliminates waste, it also saves hands from repetitive exposure to harsh chemicals.

Created and designed by eyecare professionals, the proprietary and compact design is a stylish addition to any dispensing area for quick, convenient disinfection. It operates quietly and has a fan and filtration system to ensure it doesn’t create ozone or any smells from the chamber, so you can use it while patients are in the area. Why not demonstrate it? Patients will be impressed with this cutting-edge tool and the practice’s focus on health that you display. ZEISS UVClean can accommodate frames of all sizes and is safe

for lenses and sunglasses too. It’s the little things that can have a big impact on the patient’s visual experience and their impression of the eyecare practice. One thing you can do when patients come in for adjustments, is offer to disinfect their glasses while they wait. It’s a fast and easy way to show patients you care about their health and safety.

Snapshot: Why choose ZEISS UVClean?

- Designed specifically for ECPs

- Proprietary 4 UVC bulb system

- 40 second cycle

- No liquids

- No harsh chemicals

- No smells

- No disposable waste

- Non-contact cleaning

- Small footprint

- Quiet operation

- One touch start

- Safe and gentle on frames and lenses

- ZEISS branded technology

- The “green option”

- Made in the USA

SUMMARY

Light is radiant energy measured on the electromagnetic spectrum and divided into bands. Ultraviolet light is just outside the visible light bands and is subdivided by wavelength into UVA, UVB and UVC. Each of those has ionizing properties that affect living organisms. Health care facilities have used UVC for disinfection for some time, but UVC isn’t naturally on the Earth’s surface and so must be manmade. UVC devices must be safe, precise and task specific.

New protocols for office hygiene require additional procedures, including frame disinfection. What’s more, cleaning methods have to be effective, efficient and easy to use to ensure compliance. Cleaning every frame by hand is time consuming, cumbersome and costly, initiating the search for a better way. We have seen how the ionizing properties of UVC make it a clean and useful disinfectant, and ZEISS UVClean technology has harnessed those properties in a convenient tabletop device. It will safely disinfect up to 10 frames in 40 seconds, saving time, labor and money.

It may have taken a pandemic for us to reevaluate office hygiene, but we now understand the importance of disinfection to control germ transmission. Going forward, even after the coronavirus passes, it will be important to keep hygienic practices, including frame disinfection, in place. That makes a device like ZEISS UVClean an investment in everyone’s future.