Is investing in an in-office finishing lab the right decision in a pressured economy? This seems like a reasonable question to ask when most businesses are cutting back or taking a wait-and-see attitude until they understand what consumers will do.

However, this may be the best time to add a new service such as lens finishing to a practice. An in-office lab can save you money and help differentiate your office from others, giving you a leg up on the competition. It may even be the right time for getting better pricing and terms from edger manufacturers.

Among the other plusses, in-office finishing upgrades your professional identity and is another reason for new advertising and communication with patients. It adds to efficiency, is profitable and can provide a variety of tax breaks.

Before investing in in-office finishing equipment, review the following questions, which we’ve help answer, to see if this investment is right for your practice.

Do I want to improve my competitive service advantage?

In-office edging helps retain patients who leave because they desire faster service or a better price. It allows a better ability to compete with the “super-opticals” and can increase new patients with an advertised in-office lab.

Can I increase patient satisfaction with quicker turn-around time?

Most offices will agree they receive uncut lenses faster since the finishing portion of a job is done in-house so overall they’re service times can be faster. It also allows the ability to do Patient’s Own Frames (POF) without having to send their eyewear to the lab. If it’s a three-piece rimless, this might take up to 10 days when an in-office lab would let the patient keep their glasses until the lenses are received and can be processed in your office.

Do you want to improve your professional identity and the patient’s perceptions of the practice’s technical ability and sophistication?

A “state-of-the-art” practice, helps improve control over quality, reduce errors and ensures patient satisfaction.

Can it save staff time?

If an office is doing less job tracking, there will be less negative customer communication. This can reduce time re-scheduling appointments for glasses not ready when promised.

Will it build profits?

Many practices that edge their own lenses better control critical dispensing factors by increasing sales and controlling the cost of goods.

Does it reduce lab costs?

Many save about $5 to $15 or more per job with an in-office finishing lab. This can improve cash flow. With an inventory of single-vision lenses, it’s possible to offer same-day service, receive same-day payment, solve patient eyewear emergencies and produce eyewear quicker and more efficiently.

What can edging do that will change my business?

This is the question that all should ask when considering edging in-house. First, having the ability to edge or upgrading an older edger now includes a variety of personalization tools that can help differentiate your office. Ever order a grooved rimless and request the lab add 2mm extra to the bottom of the lens shape to accommodate a more progressive reading area? New edgers have input screens that allow changes to lens size and shape (“A” vs. “B”). In fact, some blockers and edgers allow complete editing of the lens shape so that a customized shape, personalized for a wearer can be designed, confirmed with the patient and delivered for that customized look. Think about Sarah Palin and the effect she had on the popularity of rimless.

Next, control of bevel position and bevel shape allows an infinite number of improved looks for even the toughest prescriptions; it better customizes cosmetics and the overall reliability of lens retention. New edgers allow adjusting the angle of the bevel (steepen and moved to the front surface) so wrap frames or very high-base lenses can be edged in-house. It also ensures these lenses stay in the frame since steep bevels are usually required.

Lastly, for new drilling edger systems, adding drill coordinates into memory allows any optician to set up the job; press start and go off to spend more time taking care of patients. Each of these ensures that you can really differentiate your practice. For a better list of new features, see the Cost vs. Benefits Checklist.

Consider Cost

Clearly, cost is an important question. Here’s how much to budget for the equipment purchase. Edgers cost between $20,000 and $50,000. The total cost depends on blocking systems, drilling options and the service agreements. It’s also a good idea to augment in-office edging with a tinting unit at $500 to $1,000. Tinting is profitable and versatile for the office. It allows sunglasses to be made quickly, especially with standard plastic lenses. Of course, there is less tinting in favor of polarized and photochromics for glare management and AR coatings on clear lenses.

As noted, the total cost of an edging system should consider its lifetime cost, so think about service contracts and update costs. This depends on the vendor, certainly something every ECP should assess before purchasing. However, to get an initial idea of your return on investment, a simple calculator can help. It requires knowledge of volume and product mix from your lab bill. Then choose the variety of equipment wanted and approximate costs. After adding in all the data, see the bottom line—ROI Years. This is an estimate of how long, with the same conditions, it will take to pay off the purchase price of the equipment.

In this example, the lab savings of 12 jobs a day pays for a $33,000 system in less than a year. (A copy of this ROI calculator is available at 2020mag.com.)

Budget yearly for new technology. It is a good to create a five-year budget plan to upgrade and update tools and equipment. Talk in detail to the representatives from the equipment suppliers for their suggestions of the technologies and capabilities that your office can grow into, where to start and when to add. Remember, benefits are in the future, costs are in the present.

Factor in Practice Volume

From the calculator, it’s evident the payoff for the equipment is volume dependent. However; don’t forget it’s also a capability purchase that you grow into. It increases the opportunities for additional work you probably don’t offer now, such as fast service and personalized rimless shapes.

Potential Saving

How much can I save, how much profit per month/year? The answer to this question depends on the number of jobs done and the equipment that was purchased. It also is a function of the average sell price versus your cost of goods. So, while this is not a discussion of pricing, in-office specialty work like rimless takes more time so charge accordingly. Again, use the ROI calculator for perspective.

Also, consider your lab bills and construct a “Lab Savings Analysis” looking back at the last six or 12 months of bills. Be sure to ask equipment vendors to assist you in these calculations. Of course, the more work you do the quicker the pay off. Here are some average costs: (review your own lab bills for specific data) Tinting $6/pr, Edging $5 to $15, Drilling $30 (about $5/hole + edge polish + other special treatments). Another look at profits can be seen at www.briot-usa.com/profit/profit.php and the consulting services tab at www.aitindustries.com.

Space Requirements

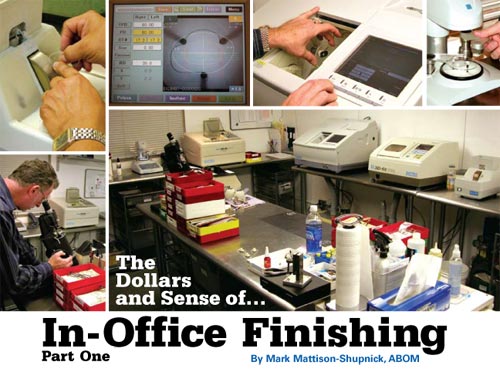

For a finishing lab the average space required is 100 square feet and that includes an automatic lensometer, edger and tracer, automatic blocker, software and PC, hand stone, tint tank (nine pot with gradient capability).

Labor Requirements

Your labor needs will depend upon the volume of work you plan to do. The skill level needed is average, but a willingness to try new things and pay attention to detail is required. Good work requires quality checks continuously as jobs are being processed. A new person should be able to process three to four pairs a day with their existing staff; when 10 to 12 pairs a day are being processed, only about three quarters of a staff member’s time will be needed to devote to the task. If there is a large volume of rimless, then consider a full-time person.