MATERIALLY TUNED PHOTOCHROMICS

By Mark Mattison-Shupnick, ABOM

Release Date: March 15, 2018

Expiration Date: April 15, 2019

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Learn about improvements in photochromic lens technology.

- Understand how in-mass lens chemistry is incorporated into the lens monomer to produce improved photochromic performance.

- Gain an understanding of the complementary patient benefits that high-index, photochromic and new lens designs have on patient satisfaction.

Faculty/Editorial Board:

Mark Mattison-Shupnick is VP, Business Development for Enchroma, an eyewear company providing glasses for the color blind. Mattison- Shupnick previously directed the education group at 20/20 Magazine on behalf of opticians and para-optometrics for Continuing Education courses and programs across the U.S. He has over five decades of experience in the optical business.

Mark Mattison-Shupnick is VP, Business Development for Enchroma, an eyewear company providing glasses for the color blind. Mattison- Shupnick previously directed the education group at 20/20 Magazine on behalf of opticians and para-optometrics for Continuing Education courses and programs across the U.S. He has over five decades of experience in the optical business.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Technical Level II Course STWJHI003-2

Supported By:

This course is supported by an educational grant from Mitsui Chemicals Inc.

This course describes the latest material improvement for photochromic casting technology. It's the "What's New" in photochromic performance technology. You'll want to understand this photochromic performance improvement and share it with your patients. It's a clever solution that changes the way that high-index and standard plastic lenses can be made photochromic, and it provides patients with the advantages of an in-mass photochromic lens solution. Use this course to better understand the MR series of SunSensors lenses. Ask your laboratory about availability. Your patients will appreciate your expertise and these new lenses.

Each photochromic lens performance improvement focuses on enhancing the wearer experience. Let's discuss which of these photochromic technologies delivers best, a material solution or a coating solution. The results of photochromic performance improvement is an increase in patient satisfaction which betters the optical business, that of the industry and that of our practices.

WHY PHOTOCHROMICS?

You know that if money wasn't an object, patients would want every benefit available to be included in their eyewear. However, the value of each option an office might suggest is weighed carefully by today's consumer. As a result, the value of each benefit must be made clear to each customer, which means that all of the benefits must be crystal clear to the optician. When you're knowledgeable about the details of "how and why" this new photochromic technology results in superior photochromic performance, you can clearly and easily define the value for your customer. So why photochromic?

As a wearer of photochromic lenses, I think that convenience, comfort and builtin outdoor protection make them the most valuable of my pairs of glasses. In fact, as a person lucky enough to have multiple pairs of glasses, I will often think about the day's activities and wonder whether I should carry a backpack to hold an extra pair of sunglasses and then decide that the convenience of my photochromic lenses is all that I want for the day. I believe all eyeglass customers would love to have this convenient option in their eyewear. It doesn't obviate the reason that this same customer shouldn't have a pair of polarized sunglasses for all the reasons that dark polarized lenses are preferred outdoors and when driving. But it does suggest that as long as only one pair of glasses stays the norm, that eyewear should be photochromic, especially for children who need protection outdoors even more than adults and who typically can't manage multiple pairs of glasses.

Why is in-mass manufacturing of photochromic lenses an advantage? How does it improve upon other photochromic technologies such as embedding or imbibing manufacturing process? The embedding process uses a thin filter layer containing the dye molecules that is inside the top surface of the lens while imbibing incorporates the dye molecules into the lens' front surface. Both processes result in thin layers of photochromic dyes near or on the surface of the lens. With in-mass photochromic technology, the photochromic dye molecules are part of the lens and are distributed throughout the entire lens. So the lightchanging chemistry isn't just added to the surface or a thin film; it's part of the whole lens. This makes these lenses supportive of all premium coatings and makes them perfect for premium lens design surfacing technologies that require dual side processing (dual aspheric, dual side progressives, complex surfaces, etc.), extreme high curve lens requirements, lined multifocals and lenses for rimless frames.

NEW SUNSENSORS

Mitsui Chemicals supplies the vast majority of high-index monomers used for ophthalmic lenses worldwide. Called MR (Mitsui Resin), you've seen them advertised in lab price lists as MR-8, MR-8 Plus (1.60 high-index) and MR-10 (1.67 highindex). New SunSensors are now tuned to these monomers. With the new SunSensors material availability, your lab can produce lightweight, premium strength, high refractive index for high prescriptions with the advanced photochromic performance customers want. When high-index lenses are not required, SunSensors 50HPM, a low-index version (1.51) is available.

Commercial availability of photochromic lenses had its origins in 1964 when Corning released glass lenses with variable tint technology, i.e., lenses changed color density when exposed to ultraviolet light.

In 1999, Corning applied their expertise to plastic lens materials introducing the SunSensors brand. Other companies further developed the technology and grew the photochromic market to where it is today, with modern photochromics available from a variety of lens manufacturing suppliers.

In 2014, Mitsui Chemicals acquired the plastic photochromic business from Corning, and as a major lens material supplier initiated development of an improved photochromic technology that could take advantage of the other lens material benefits that it already supplied to the market. During 2016, Mitsui began to test new SunSensors-50MPH and SunSensors-MR8 with its lens-casting customers. Why a new photochromic?

Until then, only a 1.56 mid-index lens was possible because the technical challenge has been to get the photochromic dye molecules to effectively disperse evenly within the lens structure, during the lens material's casting process, without denaturing the dyes. A proprietary new technique called Ultra Dye Dispersing technology now enables these new dyes to work in the current lens casting systems. And the caster can adjust the dye load (number of dye molecules) to affect how dark the lenses become in their final fully-activated darkened state.

WHY IN-MASS?

"In-mass" is defined as the mixture of a material or effect, dispersed evenly throughout the body of a lens that provides benefit. For example, high-index lens materials like 1.6 and 1.67 are 100 percent UV absorbing. That's because the lens is made from a monomer and additives, that once cast, is 100 percent UV absorbing. Lenses do not require additional treatment to improve UV attenuation of light passing through the lens. In this same way, the chemistry that makes a lens change its color density (darkness, light absorption properties) can be added to the lens monomer before casting so that the resulting lens is photochromic throughout.

Today, lens photochromic dye infused front hardcoats are typically used to render a lens photochromic. There are however, manufacturing requirements and opportunities that would benefit from having the lens body already treated so that the hardcoat, AR or other lens processing did not have to rely on a photochromic hardcoat.

For example, there are a number of complex digital single vision (double aspheric) and progressive lenses (dual surface technologies) that require front, as well as back surface cutting and polishing. Using in-mass prepared lens blanks allows the direct surfacing of these lenses as well as the application of traditional premium hard and AR coatings in standard coating units. Complex dual side lens design manufacturers are experienced in using the MR lenses that add thinness and lightness to the lens' premium design. Additionally, since the improved durability of AR is a function of the hardness of the hardcoat, improved hardness hard coating systems are then viable with these photochromic lenses.

Next, lined multifocal, bifocal or trifocal lenses use dip or spin coating technology to apply the lens' hard coat. There is a discontinuity or unevenness of the lens' surface in lined multifocal lenses which results in a wave of inconsistent hard coat thickness at the top of the segment and at one or both top corners of the segment. That inconsistent thickness is apparent in the darkened state of a lens made with the imbibed photochromic coating process. In the darkened state the lens exhibits a color density variation. For this reason, imbibed technology is not used in a traditional lined multi-focal single index lens. Embedded film photochromic technology addresses this issue but material availability was/is limited. With the new Ultra Dye Dispersing technology, not only can photochromic lined multi-focal lenses be manufactured but material availability has been expanded to include 1.60 and 1.67.

Ultra Dye Dispersing photochromic technology has another benefit in that it's available in high-index materials, for high power prescriptions. The advantage of having high-index options with this new photochromic lens technology is that the high-index lenses do not have the excessive curves that result in coating inconsistencies during manufacturing that plagues low-index lenses. Most opticians and doctors recommend high-index materials to improve thinness and lightness in their patients lenses, and now they can offer new improved photochromic performance in a thin lightweight lens.

Low-index lenses have steep curves on the back of high minus lenses and front of high plus. With this new in-mass photochromic technology, premium hard coats can be used and the irregularity of coating thickness that might affect lens color in imbibed photochromic lenses is avoided. This benefit of in-mass is also important for rimless lenses where one drills through the coating and lens. Tension on the lens around the drill holes can stress the surface, creating uneven darkening of a photochromic coating. Lenses manufactured from an in-mass product avoid this problem.

DARKENING AND FADING

Most opticians and consumers will agree, especially those that have them, photochromic lenses darken very fast. Fade time however has been a deterrent to consumer adoption of photochromic lenses. Slow to fade is a detractor for photochromic sales even though their overall benefits show that those who purchased tend to buy them again. Therefore, improving the fade time addresses two issues: consumer objections/ bias and the optician/doctor objections/ bias. All obstacles have been removed for the customer who rejected old photochromic lenses due to slow fade time and lingering color after coming indoors. New sales opportunities now exist to grow the number of loyal photochromic customers.

Removing the drawback of slow fade time also addresses optician or doctor's bias against photochromic lenses, opening up the opportunity to grow this category for the practice. Personal dislike affects sales. That's because a personal bias affects whether an option is even mentioned and worse yet is when they're mentioned but negatively. For example, how many have heard this comment, "But they don't darken in the car…?" Just as this is true for photochromic lenses so is it true of clear lenses. Yet you never hear anyone telling a person wearing clear lenses that they aren't tinted in the car. By improving fade back speed, this new improved photochromic technology offers the patient an even better photochromic experience making their lenses their ideal general purpose pair of eyewear. And to address the concern about driving…shouldn't we be recommending a good polarized sun lens? Make sure your customers know about the great improvements in photochromic lens performance they'll experience with this new technology.

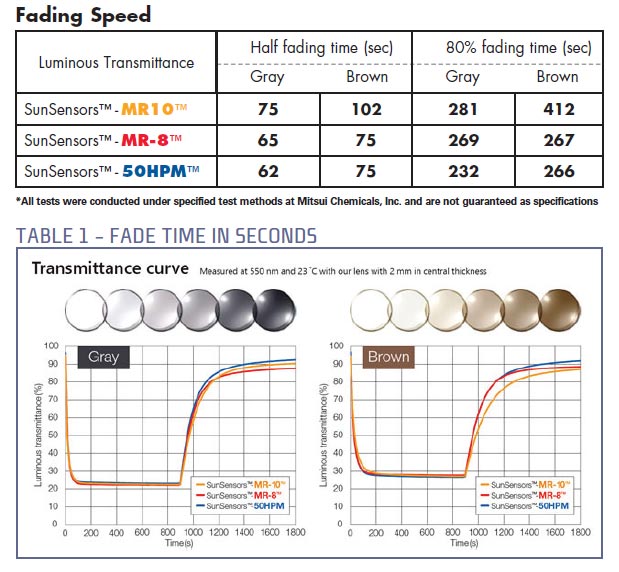

To understand new SunSensors' fade time improvement, a graph of performance shows the lens darkening and fading time by material. Table 1 dimensionalizes what can be described to a patient. Here's how.

Gray lenses fade to half their darkness in a little more than a minute, words that a patient can understand. This shortened amount is meaningful to photochromic lens wearers. In Brown, fade time is about the same, somewhat longer for MR-10. The time it takes for gray or brown lenses to be 80 percent clear is on average, 4 and one-third minutes, and brown MR-10 about 7 minutes. Table 1 shows the actual transmission curves for each of the new SunSensors materials. How do these fade back speeds stack up against other photochromic technologies? They are close to 50 percent quicker to reach a clear state.

In addition, a review of performance after accelerated weather tests shows little change to either the fade time or the clear state color. These are important benefits for the patient that keeps their glasses longer than the usual repurchase cycle. For example, the U.S. re-purchase cycle for the over 55-year-old is about 2.8 years. That means that for the customer who keeps their glasses as long as that or longer, lenses retain a near new lens performance. This is an important dimension of value for a portion of patients.

WHEN CHOOSING MATERIAL

Lens manufacturers choose lens materials and their raw chemical suppliers because of the products that they can manufacture that deliver superior lens attributes in final lens form. Those lenses must provide a promise of market preference and market success. Labs choose lens materials because of ECP demand and product sales opportunities but require in-lab processing efficiency and superior surface quality. ECPs choose lens materials because they are the foundation of the final lens that delivers patient satisfaction and saleable benefits. Each also requires an opportunity to make a profit (adapted from the 20/20 CE course "MR Material").

Almost 6 of every 10 pairs of glasses sold in the U.S. today are with thinner, lighter, more impact resistant lenses and 100 percent UV absorptive. Opticians make this conscious choice of benefits built in when choosing lens materials for patients. When asked why opticians choose "premium highindex," they suggest that the higher refractive index makes for thinner, better looking lenses, a higher Abbe number and surface finish ensures clarity, and the high impact and reduced notch sensitivity or tensile strength makes them also perfect for rimless. How have high-index lenses evolved, and what makes them a lens material choice that supports the best of premium eyewear?

Photochromics, for many patients are expensive, so durability is one key criteria of customer satisfaction. A discussion about how well their photochromic will perform for the life of their prescription (for some customers as much as twice the typical twoyear average repurchase cycle) improves the value of the eyewear to be sold. Therefore, concerns about color appearance, fading and darkening speed can be addressed and put to rest.

Product durability is an important measure of value for the patient.

Durability also means other things to casters, opticians and patients. When a lens caster chooses a material from which to make lenses, they must consider FDA 21CFR 801.410, the requirement that all lenses dispensed in the U.S. will pass the drop-ball test. New SunSensors is also available in MR-8 Plus. This monomer allows a lens caster to improve the impact resistance of the lenses they supply without compromising the index (both are 1.60) and density (1.3gm/cc3 vs. 1.31) that made ECPs purchase lenses made from MR-8. The difference was that MR-8 required an impact primer as part of the hard coating process to ensure that the subsequent lens with an AR coating would exceed the drop ball test. MR-8 Plus can remove that primer requirement. This can improve efficiency for casters and labs as they manage their lens manufacturing processes. The inclusion of the primer on an MR-8 Plus lens further improves impact resistance. An interesting application of the capabilities of lenses made from the Plus monomer can be used in the production of bifocals and trifocals with inherently improved impact resistance and photochromic performance. For non-photochromic lenses made from the Plus monomer, tintability is also significantly improved.

MATERIAL CHANGES

New SunSensors lenses released by SOMO US, will be available at the following labs:

- Cherry Optical

- Digital Eye Lab

- Expert Optics

- Luzerne

This CE course is intended to add to the knowledge base provided on MR Material in the previous product spotlight course. It also shows how manufacturers supplying lenses are continually researching opportunities to improve your business and the satisfaction of patients.

Why should you know about new upcoming technologies and material solutions? Our industry is reliant on "new." We sell a product in which the wearer relies on the benefits of better vision but they want the latest technology, and of course they want their new high-tech lenses in an exciting new pair of glasses. Vision is just one part of a pair of glasses, and while it's the usual initiating factor that drives customers to seek new eyewear, the customer gets more excited about purchasing a new beautiful frame to hold their new thinner and lighter, high-performance photochromic lenses. When you recommend technology that enhances the patient's experience, they return and they tell friends and family.

If your office does not regularly seek out "new," you risk being perceived as outdated and the patient seeking eyewear elsewhere. Perhaps the patient comes for their exam (they trust the doctor) but leave to buy their eyewear elsewhere. Be "in the know" about NEW, ask for it from your suppliers and share your excitement about what's new with every patient.