ACTIVE EYE DEFENSE

By Deborah Kotob, ABOM

Release Date: July 1, 2021

Expiration Date: July 1, 2024

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Explain the urgent need for eye protection from impact injury and the sun.

- List the common sports-related injuries to the eyes of school-age children.

- Describe the increased risk of sun exposure to young eyes.

To Earn Continuing Education Credit:

This course has been approved for one (1) hour of Ophthalmic Level II continuing education credit by the ABO. To earn ABO credit, please review the questions and take the test at 2020mag.com/ce. Note: As of January 2020, no tests will be graded manually. Please call (800) 825-4696 for more information.

Credit Statement:

ABO 1 hour, Ophthalmic Level II, Course Number: STWJHI044-2

PROTECTION

The most important conversation between the ECP and the patient/customer, especially our athletic customers, is one that educates them on all the ways to protect and preserve their eye health. In addition, the most important conversation we can have with parents warns them of the dangers and risk to sight when a child plays sports (Fig. 1) with inadequate protection.

The most important conversation between the ECP and the patient/customer, especially our athletic customers, is one that educates them on all the ways to protect and preserve their eye health. In addition, the most important conversation we can have with parents warns them of the dangers and risk to sight when a child plays sports (Fig. 1) with inadequate protection.

In a perfect world, the doctor initiates the conversation during the exam about the risks for injury, including sport-specific eyewear requirements. UV and HEV light exposure risk all need to be explained, including the fact that protection is needed even on cloudy days and should start young. The patient receives the doctor’s recommendation as medical advice. Then when the doctor writes a separate prescription for sports/safety eyewear and sunwear, it indicates that eye defense is essential to the patient or parent.

PROTECTIVE SPORT EYEWEAR

It is our responsibility as opticians to ensure that the eyewear dispensed is appropriate for the planned purpose, e.g., sports and safety. According to the Coalition to Prevent Sports Eye Injuries, wearing protective eyewear will prevent more than 90 percent of all sports-related eye injuries when explicitly designed for a given sport. Glasses, goggles, face shields and helmet attachments offer kids protection from eye injuries during school sports and physical education classes. Protective eyewear meeting ASTM guidelines when properly fit can mean the difference between safety and an eye injury. More than 40 percent of eye injuries are sport/recreational activity-related. The AOA reports that among all eye injuries reported in the Eye Injury Snapshot, more than 78 percent of people were not wearing eyewear at the time of injury. In addition, roughly 40,000 injuries result in legal blindness in the injured eye.

The National Eye Institute cites eye injuries as the leading cause of blindness in children in the United States, and most injuries occurring in school-aged children are sports related. And the report states that currently, most youth sports leagues do not require the use of eye protection (nei.nih.gov/sports). Only eyewear marked with ASTM approval for a specific sports activity should be used to produce sports eyewear (F803 standard for sport eyewear intended for racquetball, squash, handball, tennis, women’s Lacrosse and badminton, F910 for baseball and F513 for hockey).

PROTECTIVE SAFETY EYEWEAR

American National Standards Institute (ANSI) impact resistance standards require that the lenses, regardless of thickness, pass the impact resistance test. ANSI established safety eyewear standards include:

• Z-87 basic impact guidelines for safety eye wear lenses require a 3.0 mm minimum lens thickness regardless of material. Drop ball test—must withstand the impact of a 1 inch steel ball drop from 50 inches.

• Z-87+ high impact standard for safety eye wear lenses requires a minimum 2.0 mm thickness and withstand the impact of a one-quarter inch ball traveling at 150 feet/second.

• Z-87+ high impact standard applies to all safety frames.

EYE PROTECTION CRITICAL IN SPORTS

As we watch our son or our daughter approach the plate with hopes of hitting the baseball out of the park and running the bases, it doesn’t occur to us that sometimes the ball hits them instead of them hitting the ball. Baseball ranks the highest for childhood sports injuries. The American Academy of Ophthalmology (AAO) and the American Optometric Association (AOA) state that thousands of children suffer sports-related eye injuries every year. Sports is one of the leading causes of school-age children’s eye injuries, with most being preventable injuries.

As we watch our son or our daughter approach the plate with hopes of hitting the baseball out of the park and running the bases, it doesn’t occur to us that sometimes the ball hits them instead of them hitting the ball. Baseball ranks the highest for childhood sports injuries. The American Academy of Ophthalmology (AAO) and the American Optometric Association (AOA) state that thousands of children suffer sports-related eye injuries every year. Sports is one of the leading causes of school-age children’s eye injuries, with most being preventable injuries.

Both the AAO and the AOA urge mandatory eye protection in school or communitysponsored sports.

Across age groups, sports-related injuries occur most often in basketball, racquet sports and baseball. Other high-risk sports are hockey, football, lacrosse, boxing and soccer.

If a child resists wearing protective eyewear, their complaint is based on the fear of not looking cool—with eye goggles, etc. One way to overcome this is to show them pictures of professional athletes like Kareem Abdul Jabbar and James Worthy, or football star Eric Dickerson, who all wore eye protection. Also, new sport and safety frames and goggles are colorful, fun and sporty so looking cool isn’t a problem.

IT STARTS WITH OUR YOUTH

Some ways to protect our children’s eyes include:

• A child’s eyes should be checked prior to starting any sport. They can’t duck or dodge the ball if they can’t see it, and good vision will improve their game.

• Every sport has specific requirements for eye safety, and proper fit should be a requirement.

• Buy prescription glasses made of polycarbonate or Trivex material for the highest impact rating. Polycarbonate can withstand a projectile traveling at 90 mph.

• For contact sports, choose eye guards or glasses with padding at the nose and brow. It is not just the eyes at risk of impact injury, and glasses can be made safer and less likely to contribute to an injury when properly padded.

• Eyewear frames for sports should be made of polycarbonate and meet ASTM standards with strong frames that secure with a strap.

SPORTS PROTECTION

Here are protection devices recommended by Prevent Blindness America for popular sports that can cause eye injuries in children:

Here are protection devices recommended by Prevent Blindness America for popular sports that can cause eye injuries in children:

Baseball/softball—Type of eye protection: faceguard/visor (attached to the helmet). Helmet-mounted faceguards/visors are the most protective. Clear faceguards/ visors made of polycarbonate material. Polycarbonate is impact resistant, thinner and lighter than plastic, shatter proof and provides UV protection. Helmet mounted faceguards/visors should be National Operating Committee on Standards for Athletic Equipment (NOCSAE) approved (nocsae. org).

Sports eye guards (goggles or spectacles): Eye guards offer reduced protection compared to a helmet-mounted faceguard or visor but are better than a naked eye exposed to a ball with an impact that can result in eye/vision loss. Sports eye guards should meet ASTM F803-19 or the most current sport-specific ASTM standards.

Basketball—Type of eye protection: sports eye guards (goggles or spectacles). Sports eye guards used for basketball should meet ASTM F803-19.

Soccer—Type of eye protection: sports eye guards (goggles or spectacles). Sports eye guards used for soccer should meet ASTM F803-19.

Football—Type of eye protection: polycarbonate visor shield attached to faceguard. These shields offer additional protection against objects having the potential to penetrate openings in the faceguard grid. They also provide the wearer UV protection.

Hockey—Type of eye protection: wire or polycarbonate visor/shield (attached to the helmet). A polycarbonate mask attached to a helmet provides the most protection without cage wires blocking the visual field (Note: goaltenders must wear full wire cage face protectors). All hockey eye and face protectors should bear The Hockey Equipment Certification Council (HECC) approval label (www.hecc.net).

Women’s lacrosse—Type of eye protection: sports eye guards (goggles). Sports eye guards used for women’s lacrosse should meet ASTM F3077-17 standard or the most current version of that standard. Beginning in 2020, women’s lacrosse eye protectors must bear the Safety Equipment Institute (SEI) Certification Mark (www. seinet.org).

Field hockey—Type of eye protection: sports eye guards (goggles). Sports eye guards used for field hockey should meet ASTM F2713-18 standard or the most current version of that standard.

Racket sports—Type of eye protection: sports eye guards (spectacles or goggles). Sports eye guards used for racket sports (e.g., racquetball, squash) should meet ASTM F3164-19 standard or the most current version of that standard.

PROPERTIES OF SUNLIGHT: THE ELECTROMAGNETIC SPECTRUM

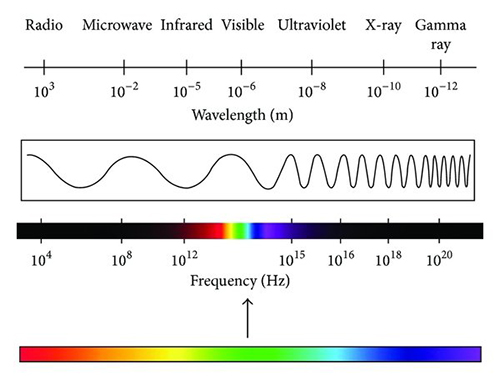

Sunlight is essential to life and sight, but there are harmful rays that penetrate the earth’s atmosphere, damaging our eyes and skin. These harmful rays are not necessary for vision. It is recommended that we prevent exposure and the correlated damage from these rays with protective sunwear.

Why must we protect our eyes from sunlight? Actinic rays, aka ionized radiation, reach us in the form of UVB, UVA and HEV (high energy visible) rays. They are the shortest wavelengths absorbed by the cells of our eyes and skin. When absorbed by the skin or the eye, these wavelengths can produce harmful effects. Unfortunately, the harm is not always immediately apparent, like sunburn on our skin or photokeratitis, a sunburn of the conjunctiva/cornea of the eye. Chronic sun damage occurs over time and can’t be seen or felt in the eye, and often goes undetected until the irreversible damage is incurred, resulting in permanent vision loss.

Actinic rays consist of invisible ultraviolet rays and visible short-wavelength violet/blue rays. Actinic rays are those wavelengths capable of causing a harmful photochemical reaction in biological cells of skin and eyes. They can produce acute temporary or chronic permanent and cumulative oxidative damage.

When our skin absorbs UVA, essential vitamin D is produced, but exposure duration must be kept short to avoid UV damage to the skin, including melanomas and premature aging. Exposing our eyes to UV rays is associated with the formation of cataracts, pterygiums, pingueculas (unsightly permanent growths in the cornea and conjunctiva) and cancer of both the eyelids and the eye itself. Visible light is essential for sight, but our eyes need protection from short-wavelength visible violet/blue light. HEV light has been implicated in retinal damage. It is cited as a possible contributing factor in developing age-related macular degeneration (AMD), an incurable and blinding retinal disease that causes central vision loss.

HEV light is short-wavelength visible violet and blue wavelengths. These wavelengths are the only visible waves that scatter in the environment, impeding vision by producing glare, loss of contrast sensitivity and loss of detail. In addition, when these wavelengths scatter inside the eye, they can also result in veil illuminance, which interferes with sharp, clear vision and contrast sensitivity. Therefore minimizing short-wavelength violet/ blue wavelengths of light protect not only the eyes but also improves vision.

Note: In addition to protecting the eyes from solar blue light, minimizing shortwavelength (violet/blue light) scatter in our clear dress eyeglasses reduces eye discomfort when spending long hours staring at device screens. Blue light scatters and contributes to blur when viewing digital device screens. When a lens reduces, scattered blue light transmission to the eye contrast sensitivity improves, meaning that details are sharper and edges are more clearly defined. For our clear indoor pair of eyewear, new blue filter AR coatings help reduce eyestrain associated with the blue light emitted by digital device screens, e.g., smartphones and tablets.

Protecting the eyes from the damaging effects of sunlight is vital for preserving vision and eye health. The best protection requires sun protection and impact protection.

SUN PROTECTION

Coverage/wrap, backside UV AR, mirror coat, blue filters, UV400 protection and blinding glare protection. The eyes are most vulnerable to sunlight between the hours of 8 a.m. and 10 a.m., and between 2 p.m. and 4 p.m. when the UV angle of incidence results in maximum exposure.

Coverage/wrap, backside UV AR, mirror coat, blue filters, UV400 protection and blinding glare protection. The eyes are most vulnerable to sunlight between the hours of 8 a.m. and 10 a.m., and between 2 p.m. and 4 p.m. when the UV angle of incidence results in maximum exposure.

V400 for sunglasses provides broader UV protection than the ANSI/ISO standard of UV380nm. Dark lenses without UV400 protection allow more UV to enter the eye since our pupils dilate more behind dark lenses.

• Both UV dyes dispersed in the lens during casting, and mirror coatings reduce UV radiation transmission (the darkness of the tint does not have any effect on UV protection).

• UV travels directly to the eye but also scatters in the air and reflects from objects in our environment, including from the back of lenses. Backside UV AR solves this issue.

• Blue light (HEV) protection in tinted sun lenses is enhanced by adding yellow and orange to the base tint color; these colors naturally inhibit visible violet and blue light transmission through the lens.

• Polarized sun lenses protect the eye from blinding reflected glare (especially helpful for driving and when outdoors in highly reflective environments such as on the water, snow or sand). According to a study on pedestrian safety by the Department of Transportation, drivers have a 40 percent quicker reaction time when wearing polarized lenses versus tinted lenses (safety. fhwa.dot.gov) for average stopping distances.

IMPACT PROTECTION

Technology improves optics, comfort and protection in sport and safety glasses, sunwear and dress eyewear.

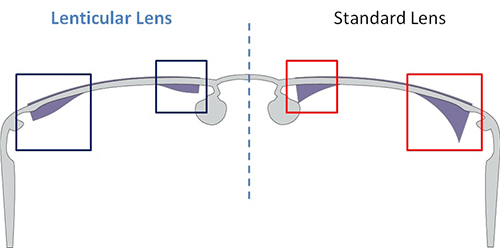

State of the art surfacing (including high wrap, base curves and for all materials): Digital design software computes the optimal lens surface features to produce the best vision, based on frame features and fit (vertex, wrap angle and Pantoscopic tilt aka position of wear measurements) along with the prescription, starting base curve and material index of refraction.

Many labs utilize lens thinning digital design technology (Lenticularization) to reduce curvature and thickness in the periphery of the lens for better cosmetics, safety and comfort in high wrap frames. In addition, design optimization of the lens surface design enhances optics from edge to edge. Finally, wrap and digital design Rx compensation are employed to produce the same Rx power in the “as-worn” frame position as the prescribed prescription power.

State-of-the-art digital surfacing goes beyond spherical base curves utilizing fiveaxis CNC lathes to apply digital lens designs with pinpoint accuracy; for thousands of points on the lens. Advanced digitally designed and surfaced lenses provide wider fields of view and increased image stability for edge-to-edge distortion-free vision with no swim effect, regardless of whether the lenses are single vision or progressive. Moreover, it improves night vision by minimizing peripheral aberrations in the lens.

FIG. 2 Image courtesy of iCoat Lab

Mirror coatings can be solid or flash. Both are engineered using dielectric process technology under controlled vacuum conditions to deliver lenses that satisfy the increasing demand for better sun protection with 100 percent UV400 protection while guarding against harmful high energy visible blue light. The latest technological advancements result in durable, antistatic, slick and easy to clean premium quality sun wear. Mirror lenses can be ordered with a special backside AR that helps reduce annoying back surface reflections prevalent on dark lenses and provide ultimate protection against damaging back-surface UV reflections. Solid and flash mirror densities: Solid mirror coatings have a higher percentage of luminous reflectance than their corresponding flash mirror colors. As a result, the flash mirror generally has a hint of color, whereas a solid mirror shows a higher density of the color. Mirror coated lenses absorb anywhere from 5 to 65 percent more light than non-mirrored lenses, depending on the color and density of the coating.

Mirrors are popular with sports enthusiasts, particularly those participating in activities such as golf, skiing, snowboarding, hunting, fishing and hiking. When combined with various tinting options and a polarizing filter, they can provide the best sun and glare protection.

• Pairing mirror coatings with polarized lenses give the best sunwear performance and protection from blinding glare.

• Perception of color to the wearer may change when looking through a tinted mirror sunglass. Tint colors must not interfere with traffic signal color recognition.

Tint color considerations: Tint color samples and polarized demonstration tools are highly effective in helping the customer see the benefits. Guide their decision by advising them on the best colors and lens treatments for their particular activity. For everyday use, outdoors in moderate to bright sunny conditions, dark tints and hues work best. The dark colors typically include brown, gray and green. Gray and green lenses maintain color neutrality, while brown lenses are high contrast making greens, yellows and reds POP; on the downside, they will cause the sky to look less blue, dulling it with a brown cast. Sun lens choices for moderate to low-level light conditions are colors such as amber rose and vermillion. Lighter tints and hues are often preferred by those who participate in snow sports such as skiing or snowmobiling because they can enhance contrast in the presence of tricky flat light conditions.

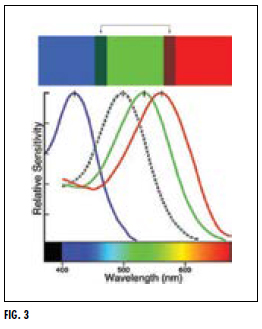

Most performance sunglass manufacturers offer color-enhancing lenses that filter the visual noise of overlapping wavelengths (Fig. 3) in the visible spectrum to produce saturated colors that make individual colors POP. Athletes love these lenses, which can be tuned to make the colors most prevalent in their sports environment vivid.

Yellow lenses are an excellent choice for hunters or shooters who prefer yellow lenses that brighten their surroundings and sharpen contrast making details and edges sharper against the background resulting in higher definition vision.

A solid mirror coating will reduce more light transmission by reflecting more light from the front surface of the lens than a flash mirror coating. However, ANSI requires a minimum light transmission of 8 percent, and for this reason, a mirror coating is not recommended for tints with less than 20 percent visible light transmission (VLT).

State-of-the-art AR coatings: We know the main advantages of AR coating are improving optics when viewing the world through lenses by increasing visible light transmission and reducing the effect of internal lens surface reflections. Moreover, AR makes the lenses cosmetically appealing by minimizing surface reflections from the front of the lens that obscures the wearer’s eyes.

Newer AR stacks use neutralized polarity to increase antistatic effectiveness to repel dust, dirt and lint. The result is increased durability with less cleaning required. Ionassisted deposition and proprietary chemical composition of the stack produce ultratough chemical layers that are virtually impervious to wear and tear in the currently available state-of-the-art AR coatings. In addition, super oleophobic and hydrophobic topcoat coats seal the AR layers with a super slick polymer-based topcoat that protects against smudges, fingerprints and moisture to promote easy cleaning of the lens.

• Backside UV AR coating minimizes harmful UVB and UVA reflections from the back surface of the lens into the eye.

• Blue filter AR coatings on clear lenses help reduce digital eyestrain.

Athletes benefit from anti-fog coatings: Anti-fog coatings are recommended for ophthalmic lenses, safety goggles, face shields, sport eyewear and industrial applications. Premium anti-fog coating reduces water droplet surface tension to disperse into a continuous thin sheet that provides clear fog-free vision. Anti-fog coatings can be applied to any lens style in a large variety of materials, including plastic, polycarbonate, Trivex, acrylic hi-index and mid-index materials, as well as glass substrates. In addition, anti-fog can be applied to lenses with AR, mirrors and scratch-resistant coatings.

STATE-OF-THE-ART EDGING AND FINISHING

Lab surfacing and finishing technology has advanced over the years and now employs fully automated, fast and precise multi-tool freeform edging systems. The latest freeform edgers cut the lens surface with a five-axis computer numeric controlled (CNC) generator producing the most complex and challenging jobs, even partially shelved lenses for fashion sports frames. Intricate lens edge processing (with base curves from 0 to 16 diopters) from various edging angles is possible and with the highest degree of accuracy. Challenging lens shapes and wrap designs are achieved with the latest six spindle edging tools; even complex bevels (step and shelf ), notches, grooves and drilled (lateral) lenses are achievable. The newer smart bevel function of these machines automatically places the bevel according to frame base and lens thickness.

In summary, as opticians, we provide solutions tailored to lifestyle, sports and sun protection. Every customer deserves to know the importance of protecting their eyes and their children’s eyes from sun damage and impact injury. To communicate this vital message effectively and confidently, we must know the hazards and risks from sunlight exposure and impact injury. Advocate for eye defense and be the sport eyewear expert. Winning is a key theme in sports, and protecting eyes from sun and impact injury is a Win, Win!