Improving Free-Form Lenses with Variable Base Curves and Digital Individualization

Product Spotlight: Camber Technology—A Unique Patented Variable Base Curve Digital Progressive

By Mark Mattison-Shupnick, ABOM

Release Date: July 1, 2015

Expiration Date: December 1, 2018

Learning Objectives:

Upon completion of this program, the participant should be able to:

- Learn why variable base curves can improve the optical characteristics, range and cosmetics of digital progressive lenses.

- Understand the functional differences between each of the progressive lens forms.

- Know the advantages of Camber lenses when producing free-form progressive lens prescriptions.

Faculty/Editorial Board:

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Course STWJH623-2

This course is supported by an educational grant from Younger Optics.

INTRODUCTION

INTRODUCTION

For every power, there is an ideal base curve. The industry, for various reasons, doesn't strictly adhere to this principle, but it's crucial to note that base curves are still very important. As it turns out, good optics are more closely related to base curve than typically thought. With that recognition, Younger Optics released a new lens technology called Camber, a new and unique digital progressive lens solution that uses a variable base curve on its front surface to widen the clear field of view from far to near. This course teaches how Camber combines the traditional optics of base curve choice with modern digital processing.

WHY HAS BASE CURVE CHOICE DOMINATED LENS SELECTION AND PROCESSING?

As you know, the combination of front and back curve provides lens power. It doesn't matter what curves are used to make a -3.00D lens for central power as long as the result is -3.00D. However, the curves chosen do affect the sharpness of the off-center areas. Because of this, front curve choice (base curve) has been a guiding principle for more than 200 years in the quest for better ophthalmic lenses.

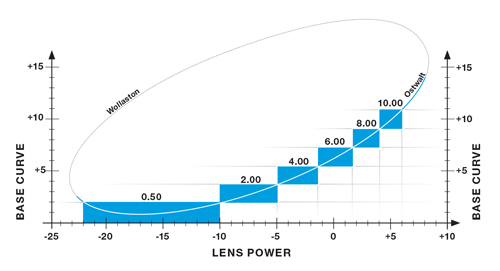

For every lens power, there are actually two base curves that offer clear vision off-center. In 1804, Wollaston developed an elliptically curved line graph matching each lens power to an "ideal" base curve, which is free from oblique astigmatism (peripheral blur). However, these early lenses were very steep, with base curves of almost up to 20D; therefore, a more practical solution was sought. In 1898, Ostwalt discovered that Wollaston's elliptically curved line graph had a lower half (Fig. 1). This meant that each lens power had a second ideal base curve. Though both base curves reduced peripheral blur to almost zero, Ostwalt's base curves were adopted as standard because they were flatter, more practical and better looking than Wollaston's. Originally, each and every lens power had a different recommended front lens curve. The glass lens manufacturers of the time found this to be unmanageable and way too costly. Therefore, they reduced the number of available base curves and began to produce a range of prescriptions from each one.

FIGURE 1 Tscherning Ellipse combining the Wollaston and Ostwalt suggested base curves for reduced oblique astigmatism |

This simplified Ostwalt system is the basis for the modern base curves that are still used for most single vision lenses and traditional progressives. Over time, industry standards have shifted toward flatter curves than those initially suggested by Ostwalt, in order to improve eyewear cosmetics. In times when style dictates small frames, this shift does not result in noticeable oblique astigmatism, because smaller frames mean a shorter distance from center to edge. However, when frames are larger, the demand for flatter, more attractive lenses often leads to sacrifices of optical quality.

CAN A SINGLE VISION LENS BLANK SATISFY THE BASE CURVES REQUIRED FOR THE DIFFERING LENS POWERS IN A PROGRESSIVE LENS?

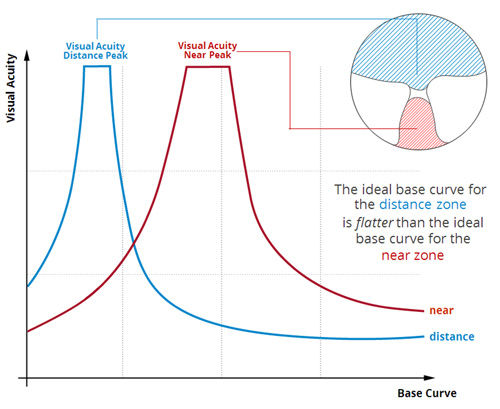

As explained, historically, for every power there is a "correct and best" base curve. Move away from the ideal base curve and the ability to control peripheral blur decreases. That reduces the clear field of view. If we're making a backside progressive lens, and we choose a SV lens blank whose base curve corrects for distance power, that curve is not the right one required for near vision, a power of less minus or more plus (Fig. 2). In most cases, more than one base curve would actually be required for correct optics.

FIGURE 2 Increased plus power to create the addition power requires different base curves; steeper in front surface progressives, flatter in back-surface progressives. |

Historically, traditional fixed front surface progressives have been widely successful. Traditional progressives are able to provide accurate optical correction because there is a varying curve inherent within the molded front surface design. In contrast, modern backside digital technology applies the progressive design to the backside of a spherical lens blank. This creates an intrinsic compromise, because the single base curve can correlate to the distance power or the near power, but not both at once. This usually means that the near zone power is not appropriately matched to its ideal base curve. Because the near zone is viewed obliquely, this mismatch is of greater consequence.

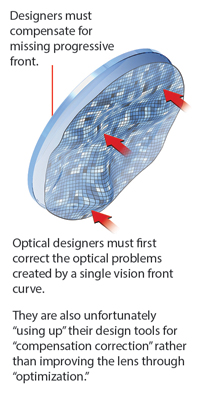

FIGURE 3 An optimization dilemma of back-surface progressives |

Optical designers (Fig. 3) must first correct the optical problems created by a single vision front curve. That makes sense and is an advantage of digital processing. However, the design tools are also unfortunately using up their compensation correction for a less than ideal base curve rather than improving the lens through optimization.

ISN'T ALL DIGITAL TECHNOLOGY/FREE-FORM BETTER?

Do you agree with the statement, "Free-form, i.e., digitally-compensated lenses produce more satisfied patients"? I know most do agree, because when I ask that question to those in attendance at my classes, almost all of them selling digital lenses say they agree. However, as many have experienced, results vary depending on how judiciously the free-form processes are applied. In fact, that range of free-form processing capability is what provides a good, better and best choice of lenses.

While all digital lenses use compensation to improve peripheral vision, keep in mind that the more compensation is required, the less optimization is possible. That is to say, reducing the need to compensate expands the lens' personalization and optimization opportunities.

In cases where an overly flat base curve is chosen (for example, a low plus Rx in a large, flat retro frame), or an overly steep lens is chosen (for example, a -4.00D Rx in an 8-base sport frame), free-form compensation may be applied to improve peripheral vision. However, because the base curve of the chosen blank is not ideal for the power of the lens, more compensation is required, sometimes more than possible. Maintaining the "ideal" base curve reduces compensation requirements.

A NEW METHOD TO DELIVER VARIABLE BASE CURVES: CAMBER TECHNOLOGY

New Camber technology combines complex curves on both lens surfaces. The continuously changing, special front surface uses more traditional, flatter curves for distance and steeper curves for near, thereby providing the optically correct base curve throughout the lens.

FRONT SURFACE INNOVATION

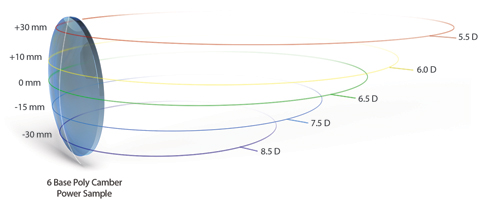

Camber lenses have a continuously increasing front surface curvature that can be thought of as a "stacking of consecutive spheres." There are eight available base curves (0.5, 2, 3, 4, 5, 6, 7 and 8 base). Each of these comes from a successive section of a spiral-shaped curve, which is shaped almost like an elephant's trunk (Fig. 4). This means that the Camber front surface increases in base curve from top to bottom—lower diopter in the distance zone, higher in the reading zone. It might help to imagine an endless stack of discs with decreasing diameters and therefore increasing base curves. Here you see an example of a 6-base lens (Fig. 5). This "stacking of the spheres" is a totally new idea, unique to Camber lenses.

The variable front curve (white line, Fig. 5) has an "umbilic" corridor with a constant rate of power increase from top to bottom. In other words, a 6-base Camber blank is only 6.50D through the horizontal middle. The blank flattens toward the top to a 5.50D curve. As you go down, the curvature of the lens increases from a 6.50D curvature to 8.50D curvature. As a result, there is a total of about 3 diopters difference from top to bottom. In steeper base curves, the total increase is greater, due to the nature of the "Elephant's Trunk" curve (Fig. 4).

This patented, continuously increasing base curve is ideal for the increasing power profile of free-form progressive lenses.

FIGURE 4 Eight different base curves mimic the elephant's trunk, increasing in diopter from top to bottom. |

FIGURE 5 From top to bottom, the front curvature constantly increases in diopter. |

DIGITALLY INDIVIDUALIZED BACK

When combined with a sophisticated back-surface digital design, both surfaces work together to accommodate an expanded Rx range, offer better cosmetics (flatter) for many prescriptions and deliver user-preferred near vision performance.

To produce Camber prescription lenses, cutting files are optimized using "Digital Ray-Path," a lab calculation software designed by IOT (Indizen Optical Technologies S.I.). Considering prescription, frame and fitting requirements, Digital Ray-Path minimizes oblique aberrations, point by point, across the lens surface. Fig. 6 shows the 3D field of view assessed by the IOT calculation engine to determine the correct Camber lens blank and the rear surface design. The Camber design and Digital Ray-Path technology work together in a complementary way to maximize the benefit of the Camber variable base curve front surface.

| FIGURE 6 The required back lens surface is calculated for a 3-dimensional space for far, mid-range and near vision. |

|

FIGURE 7 The calculated back surface is combined with the correct Camber blank to produce the resulting progressive. |

Individualization parameters are merged with the Camber prescription design computation to become the guide for processing the back surface of the Camber lens. When the digital back surface combines with the unique Camber front surface, this forms the desired progressive prescription (Fig. 7). This delivers improved visual acuity for all distances and gaze directions.

WHAT ARE THE CHALLENGES OF CURRENT PROGRESSIVE LENS FORMS?

In a traditional progressive, the increased curvature of the addition produces increased magnification. That effect is lost in a SV front, back-surface progressive. As a result, a patient might say, "Reading is not as good." The effect of a free-form progressive is lesser because it doesn't have the same effective magnification ability. Magnification can improve the reading visual experience and increase visual acuity at near, compared to back-surface progressive designs.

Eye rotation is required to read through the near zone of a progressive lens. The flatter the lens' front surface, the more oblique the angle. In a back-surface digital progressive, increased digital compensation is required to correct for that off-center obliq uity. This is one factor where the traditional progressive, with a steeper curve at near, was more optically correct.

Eye rotation is required to read through the near zone of a progressive lens. The flatter the lens' front surface, the more oblique the angle. In a back-surface digital progressive, increased digital compensation is required to correct for that off-center obliq uity. This is one factor where the traditional progressive, with a steeper curve at near, was more optically correct.

Many people feel that by putting the progressive on the back, the patient is getting a wider corridor because it is closer to the eye. While this may be true, it is not without controversy. Some suggest that if the eye is closer to the corridor, the same eye rotation spans a shorter arc, so the corridor needs to be shorter. A shorter corridor produces more peripheral astigmatism than a longer corridor would have. A shorter corridor is also narrower, which is less desirable. Also, some designers feel that the distance saved by putting the progressive on the back is very small, if you consider that the entire distance we're talking about is from the front surface of the lens to the back.

Lastly, though it may be good to have the prescription close to the face; the downside is that in high plus, back surface progressives, it may be too close, which can interfere with comfort. An example is "lash crash"—where eyelashes touch the back surface of the lens. If it is significantly high plus, the lens may require a convex add, which reduces its cosmetic appeal and may even be impossible for the lab to fabricate.

Camber's front lens surface with variable base curve addresses these concerns. The higher curvature in the near zone provides increased magnification. It also allows the use of cosmetically desirable, flatter front curves in plus powers. It's interesting; sometimes looking back to fundamental optical principles is the most effective way to move forward.

DISCUSSION: WEARER TEST

IOT, in association with the University of Madrid, designed and conducted a double-blind wearer trial comparing a Camber finished lens with one processed from a single vision blank. Both used the same contemporary IOT back-surface progressive design technology. Both prescriptions were made from the same material, same central base curve, in the same frame, and worn for one week each. The only difference between the two pairs of eyewear was the lens blanks they were processed from: Camber versus single vision. Wearers and testers were unaware of which lens was which. After trying them both, wearers were then asked to compare lenses.

When asked, "Which lens do you prefer the most?" wearers preferred Camber 2 to 1. Regarding ease of adaptation, 8 of 10 reported that adaptation to Camber seemed easier. Nine of 10 reported better near vision. Considering all factors, 55 percent (a majority) found Camber better, 39 percent found it to be equal.

Wearer trials like this are not very common today because it is very tough to show significant differences in wearing experiences. Test subjects find it difficult to differentiate and express their preferences. Additionally, the trials are very expensive and time-consuming to perform. Therefore, these reported results are significant.

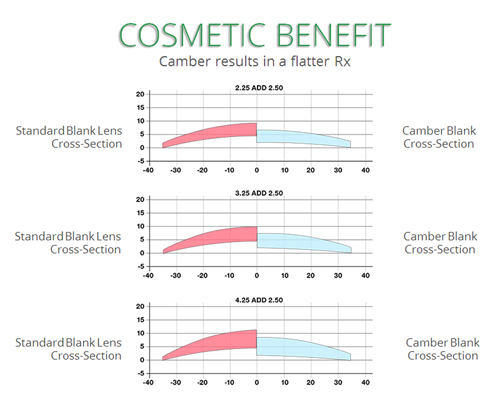

IS CAMBER SUGGESTING STEEPER BASE CURVES IN GENERAL?

No—while optically ideal base curves are steep, Camber lenses are flatter. Clearly, patients (and their opticians) accustomed to newer, flatter lenses, won't accept lenses with extra bulge and thickness. Prescription for prescription, the variable base curve Camber blank is, in fact, flatter than recommended traditional progressive lens curves. Fig. 8 compares a cross-sectional view of a +2.50 add lens on an equivalent 2.25D, 3.25D and 4.25D base curve. You can see that the Camber lenses are flatter. Typically, a flatter base curve would be chosen, resulting in a more appealing finished prescription.

FIGURE 8 |

WHICH FACTORS ARE IMPORTANT IN DISPENSING A PROGRESSIVE LENS DESIGN?

Critical: When delivering a finished progressive lens to a patient, the most important factor is not the work of the lens designer or the laboratory, but you—the dispenser. That's because the decisions you make to construct the finished product affect the patient's satisfaction. We assume the critical factors of a proper refraction (correct prescription, fitting height and PD measurements) have been done correctly. Of course, if these three items are not correct, it doesn't matter how good some of the other options might be. The eyewear will not be successful.

Important: These include base curve selection, progressive design, corridor length, primary uses and lens material. I often get asked, "Which progressive design is best?" The answer is not in the design, but rather in all the parameters required to build those glasses. That's what makes patients happy.

The design of the progressive, while important, is not any more significant than the other items in the list. One must weigh each to build the final lenses. For many people, lens material and its thinness and lightness may be of utmost importance toward a successful pair of glasses. Others may have very different demands.

Nice to have: I also believe that customizing or tailoring a prescription with the individual wearer's parameters is definitely of benefit. Judging by the number of offices that actually use position-of-wear measurements, it's clear that it's still a "nice to have," but first, the factors in the "critical" and "important" categories require mastery.

PATIENT BENEFITS

Finally, any lens' success, regardless of its attributes, depends on the benefits that it provides for both the patient and you, the ECP. Camber progressive lenses have been designed to use two surfaces rather than just one. The variable base curve front improves optimization possibilities. The steeper front curve in the reading zone eliminates peripheral blur while it delivers a wider reading area with an increased and appreciated magnification effect, all without the harsher distortion effects of traditional progressives. This design is automatically optimized and can be customized with position-of-wear measurements such as vertex, tilt and wrap. And because of the blank's variable base curve, the design calculation can use its computational "firepower" for optimization rather than compensation.

AVAILABILITY

Camber has a wide availability to suit all patients, including clear, Transitions Signature VII Gray and Brown, and NuPolar polarized. Materials include hard resin, polycarbonate, Trilogy Trivex, and 1.60 and 1.67 high index. Camber is available in the following base curves for a complete prescription range: 0.50, 2, 3, 4, 5, 6, 7 and 8D. NuPolar Trilogy and 1.74 (clear and Transitions) will be available in 2016.

CONCLUSION

Variable base curves, digitally-optimized and individually constructed, address a number of issues and produce better, more satisfying progressive lenses. Looking back to move forward, in this case, made a lot of sense.