|

Your monthly guide to staff training outside the box

Eyes / Lenses / Fitting Lenses / Free-Form / Frames / Sunwear / Patient Solutions / In-office / Standards

FRAMES, Rimless

TEMPLE TENSION, 3-PIECE RIMLESS

To adjust the endpiece, inward or outward; place the bracing plier over the mounting screws or compression posts. Then place the flat/round plier with the round post inside the endpiece. Squeeze tight and increase or reduce the curve of the endpiece. The endpieces should be angled about 90 degrees from the front.

See Plus »

|

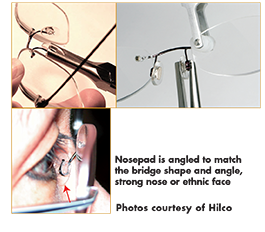

NOSEPADS: 3-PIECE RIMLESS

Most pad arms are soldered to the back of the bridge. The bracing plier firmly holds the frame while manipulating the nosepad or pad arm.

When the bridge of the patient’s nose is flat, the pad should be angled to be flat against the firm part of the nose. Consider removing the nosepad, grasp the loop of the pad arm with a needle nose plier and rotate the pad arm parallel to the nose. Then replace the pad on the loops of the pad arm.

See Plus »

|

|

|

RIMLESS EYEWEAR

By Preston Fassel, BS

Rimless eyewear can be a unique work of optical art. To this day, I’m still a fan of rimless glasses and still value the magnificent possibilities which they offer wearers. Although a custom look is one of the principal end goals in frame selection (after accounting for all factors conducive to the wearer’s prescription), total customization is still limited by the physical confines of rimmed glasses. There’s no way to stretch or shrink or reshape a rimmed frame—what’s offered is what’s offered, and it’s a matter of finding the right combination of size and angles for the wearer’s face. A skilled optician working with the proper equipment can tweak the lenses to the wearer’s facial features and specifications while also taking into account Rx accuracy and other wear variables.

See Plus »

|

ISSUES, LENS MATERIALS

By M. Mattison-Shupnick, ABOM

Rimless eyewear can star crack at the drill holes or within the groove of semi-rimless. From the lens material point of view, it’s the notch sensitivity and flexural strength of the lens material used that allows a star crack to grow. Lens materials have varying notch sensitivities, and those highly sensitive like standard hard resin are rarely if ever used for rimless eyewear.

See Plus »

|

FRAME CONSTRUCTION MATERIALS

For some mounting systems, lenses loosen easily and need to be tightened or renewed. In fact, once lenses begin to loosen, tightening is required more often until renewal is required. In a screw/nut rimless frame, the nut may be over-tightened, compressing the lens more, leading to a faster loosening and exploitation of any micro-cracks at the entrance or exit of the drill hole. This loosening is a problem especially for rimless since most U.S. consumers own one pair of current Rx glasses. Combined with the fact that many offices are less experienced in adjusting rimless, and many cannot disassemble and reassemble a frame when renewal of lenses, screws or bushings are required, the frame needs to be sent to the laboratory for renewal and repair. Patients can be left without their primary eyeglasses for up to a week.

See Plus »

|

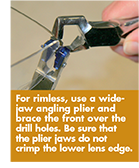

PANTOSCOPIC TILT

By Andrew S. Bruce, LDO, ABOM

When changing pantoscopic tilt, use the wide-jaw angling pliers to change the angle of the temples while bracing the frame front with a separate pair of pliers. Carefully apply force in the direction needed. This is especially important when handling three-piece rimless mountings. Protect the lens from the force necessary to change the tilt with bracing pliers such as the “three-piece adjusting pliers.”

See Plus »

|

MOUNTING SCREWS, 3-PIECE RIMLESS

Rimless mountings will ultimately become loose where the lens is mounted to the frame. Tightening the fasteners in a screw and nut mounting is straightforward; often all that is needed is an optical wrench to tighten the retaining nut.

See Plus »

|

TRICKS OF THE TRADE

For drilled rimless: Trivex material is the least affected by drilling, so it reduces or eliminates the possibility of star cracks or breakage. That same tensile strength and lack of notch sensitivity allow thinner edges on grooved semi-rimless since the groove wall is unlikely to chip or flake. In both frame styles, it reduces the number of remakes and improves patient satisfaction.

See Plus »

|

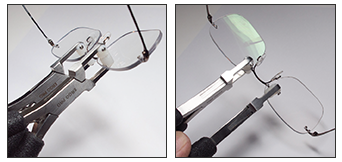

ADDING FACEFORM: 3-PIECE RIMLESS

Two pliers are used to make the faceform bridge adjustment (top left). Brace where the hardware passes through the lenses (this removes the stress on the lens when the bridge is adjusted). Use the double nylon jaw gripping pliers to angle the bridge so the curve is more “inward” or as needed. The adjustment should be made on both sides of the bridge. Use two pliers to align lenses.

See Plus »

|

|