While frame repair really can be as simple as popping a screw into place, there are situations, which can prove more difficult, and tools, which can greatly aid in the process.

Image: Hilco |

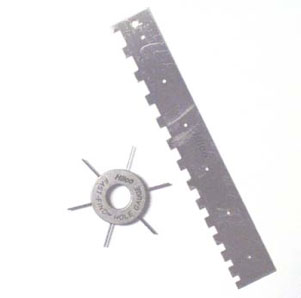

In the event that an unusual screw size is called for, finding the proper screw is easiest when the screw needing replacement is brought in by the patient. Often, patients will salvage the screw themselves and bring it in, lacking the proper optical tools to replace it themselves. In other instances, the screw may still be partially attached to the frame, needing either tightening or replacement due to worn threads. In either event, a device called a Screw Checker can be used to determine the right size for the job. A Screw Checker is a sheet of cardboard or metal, which has been drilled through with a variety of holes, each accompanied by a measurement. By inserting the screw into holes, it is possible to determine the proper diameter for the job.

In the event that the screw is completely missing, you can determine the right gauge using a Screw and Hole Gauge. A Screw and Hole gauge is a small wheel with various sized "spokes" that are inserted into the empty barrels of a pair of glasses until the spoke slides in snugly, giving you the proper screw diameter.

Re-Lengthening

As mentioned above, diameter is more important than length in replacing screws; as long as the screw is long enough, it can be resized. In many instances, using a longer than necessary screw may even be beneficial to the patient if it sticks out just slightly: If it is not long enough to pose a hazard to the patient, a longer than necessary screw can provide extra stability and help to keep it in place. If you need to shorten a screw, you will require a pair of wire cutters as well as a tool called a screw head file. A screw head file is a cylindrical tool similar in appearance to a screwdriver with a small, round file at the tip for precision filing. First, use the wire cutters to snip the screw down to an appropriate length. Then, use the screw head file to smooth the sharpened edge down. Re-cut and re-file as necessary.

Broken Screws

In some instances, a screw head may completely break off of the screw, leaving a section of it stuck inside of the barrels with no means for removal. This happens when screws are tightened too much and the threads lock in the barrel while the portion below the head continues to turn until it twists and breaks. In this event, the use of a screw extractor is required. There are two types of screw extractors currently available: Drill or pressure extractors. Drill screw extractors are long, thin cylinders of metal with tiny teeth at the end which grip the shaft of the broken screw and allow it to be removed through a standard screw rotating motion. Pressure extractors are a new type of extractor vaguely resembling a guillotine: The barrels are lined up with a pin, which is then driven down onto the screw, breaking the threads, forcing it out.

|

Many opticians with large or larger than average hands will often have difficulty in handling screws. This can make screw replacement particularly frustrating. In order to more easily handle and insert screws, use a magnetized pair of bent snipe nose pliers in order to lift and insert the screws; the curved nose of the pliers will aid in visibility when inserting the screw, leaves enough a point to allow for easily manipulating the screw around the barrels.

IT'S A SNAP: SPRING HINGE REPAIR

As we have already discussed, spring hinges are more difficult to repair than standard hinges, and are most easily fixed with a Snap-It screw.

|

The long, thin sliver of metal at the base of the screw will help to bring the spring, as well as the barrels, back into alignment. Simply align the barrels as best you can, keeping the temple in a "closed" position. Then, insert the Snap-It through the barrels, guiding it with the snap-off base. Once the threads have come into position, screw it into place. Once the screw is firmly in place, snap off the bottom of the screw. If the frame is salvageable, the temple should stay in place and become functional again.

If the proper tools are on hand, and one has sufficient experience, another option is soldering the temple barrel and its extension into the spring housing. This is a process that should not be undertaken without sufficient training, experience, and a hands-on knowledge of soldering tools and procedures.

DON'T BE SCREW LOOSE

Over the course of your career as an optician, you will have to replace an untold number of screws in a variety of frame types. This can often be a difficult process, and one during which clumsy or inexperienced hands may break the frame, leading to patient conflict. Understanding the intricacies of screw replacement and repair—along with practice, practice, practice—will help you in fine-tuning your skills and becoming a repair whiz.