By Clodagh Norton

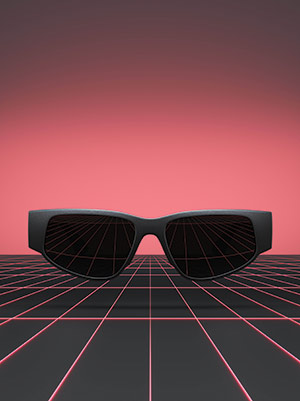

Earlier in 2019, Mykita released Heroes of Futurism, a campaign for Mykita Mylon based on the aesthetic of ’80s futurism. How did this concept for the campaign come about, and how did this correlate with the design of the frames themselves?The idea was to show the Mykita Mylon collection in the digital world that it comes from—the familiar wire frame motif signifies the digital 3D production process that is used both to manufacture the Mylon material but also the campaign imagery, which was created entirely in CGI. We also wanted to return to that potent sense of transformation and possibility that ’80s futurism saw in digital because it reflects the faith and feelings we have in 3D technology and the Mylon collection—our heroes of futurism.

Heroes of Futurism campaign

Would you say the revival of ’80s and ’90s “futuristic” concepts and the design language of those decades is particularly relevant right now in eyewear and as we approach 2020?

The desire to explore an alternative future often has a lot to do with the growing anxiety of the present day. For us questioning tradition and conventional ways of doing things is part of our identity, we are driven by an urge to find a better way. Not being from fashion or the traditional eyewear industry, our access point comes from an industrial design perspective. Material research is our starting point; from there we explore how we might create a coherent design concept. The modernity or even futuristic aesthetic of our frames is inherent in the materials and technology that we are using.

The Mykita Mylon collection is based on our proprietary polyamide made using 3D printing technology. The unique properties of this material enabled a freedom in design that made these oversized shield and hybrid sunglass visors possible.

Talking about the future, Mykita Mylon sets the bar high in the field of 3D printing in eyewear. How is this collection now evolving eight years on?

We have always placed value on the end product. For some there is a novelty in the process, but additive manufacturing was not interesting to Mykita unless it could deliver a high quality product, one that is inherently desirable on account of its “look and feel” and performance. Consequently we believe in the “premiumisation” of the 3D-printed eyewear, and we continue to enhance every detail within our own Mykita Mylon collection to ensure its status as a premium high-tech product.

We are continually working to develop the Mylon collection. We already have an extensive hybrid eyewear line that fuses Mylon with other materials, such as stainless steel. The Mykita Mylon Hybrid collection really brings together the core competences of our modern manufactory: precision craftsmanship and advanced technologies. The Mylon material is a core ingredient in our design process and also gets used across a number of designer collaborations, including Maison Margiela, Bernhard Willhelm and Tim Coppens. As a design ingredient, the Mylon material and our experience in using it continues to open new opportunities for collaborations with interesting partners ranging from the world of fashion to technology.

We are also pioneering the project My Very Own—our future vision of digital bespoke eyewear. MVO would take the technology behind Mylon to the next level by incorporating 3D facial scanning and creating frames that are tailored to an individual’s personal physiognomy. For this product to offer true added value to the customer, you cannot be superficial. Our current focus is exploring how the process can be refined to create a product of a truly superior look and fit, function and visual performance.

What did you launch at SILMO for Mykita Mylon?

The latest crop of Mykita Mylon models features a new partial lacquering technique that introduces bicolor options to the collection. Sunglass duo Peak and Canyon illustrate the 3D manufacturing expertise of our Modern Manufactory, showing the design potential of the Mylon material with ultra-slim shutter detailing on the nose bridge and side shields.

Is the way in which 3D printing in eyewear is developing now very much what you were expecting when you first launched Mylon in 2011?

I think the fact that other companies followed our example and wanted to join the market confirms the relevance of the product. Mykita set the foundation of a new category in eyewear, other players joining the field serves to differentiate the market. The consumer gets a chance to understand the variety in quality and appreciate the difference.

Is there a long way to go in terms of design opportunities/innovations in 3D printed frames—in the years ahead?

The palette within our own Mylon collection has grown year by year, and we continue to invest in the research and development of refining and finishing processes for additive manufacturing. We still consider there to be much hidden potential within the production process. Currently the limitation seems to reside with the rapid manufacturing industry—there is a need for investment in the R&D, which is simply too much for an independent manufacturer like Mykita.

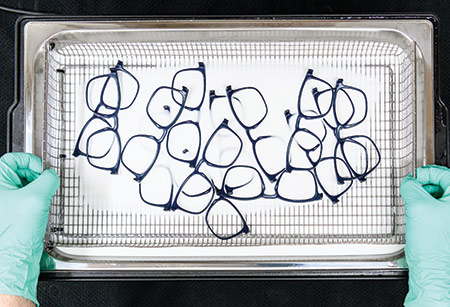

Hydrophobic treatments for Mykita Mylon models

What is the perception of your customers about the achievements of Mylon and 3D printed frames?

Mylon is light, sturdy and thermally adaptable without memory effect, which means it will retain the shape you give it—essential properties in the world of eyewear where frames must be adjustable to perfectly fit each person. 3D technology does offer complete freedom of design, and at 30 percent lighter weight than acetate, the Mylon material makes voluminous frames much more comfortable and wearable. In addition, the durability of the material enables slender constructions or smaller functional parts that are not possible with acetate. In this way, Mylon has allowed us to push conventions and create new aesthetic codes within eyewear as with sunglass styles Peak and Canyon, which was presented at SILMO.

In addition, the Mylon production process absolutely fits our independent approach to eyewear design and manufacturing. At the Mykita Haus in Berlin, we bring all departments under one roof to form what we refer to as the Modern Manufactory. This setup allows us to directly guide the product from conception to the shop floor. Our short throughput time enables a highly sustainable production across all our collections in the way that Mykita is practically made to order. The laser-sintering process behind Mykita Mylon is particularly resource-friendly with minimal material waste, which gives it additional appeal and value.

Finally, what is your personal opinion on the significance of the approach of the year 2020 for your company Mykita and the eyewear industry in general?

Will the year 2020 bring perfect vision? I can’t say. I do think we will see dramatic changes within the next three to five years in a disruptive eyewear business. At Mykita, we will continue to concentrate on using our ingenuity to craft the best product experience for our customers: A strong brand paired with personal service and the expertise found at our shops and optical partners is a recipe for sustainable, mutual success. Mykita follows a multi-channel approach, activating customer leads from our digital channels and leading them to a brick-and-mortar environment. I think the future strategy in eyewear is strengthening the bond between sought-after brands and forward-thinking opticians. ■