Photo by Stephen Mark Sullivan; Frame: Calvin Klein 5448 from Marchon Eyewear

By Palmer R. Cook, OD

Keep a high powered minus lens, finished but uncut, lens blank to demonstrate the increase in thickness that occurs with increased lens size. This lens is a crown glass lens, 65 mm in diameter, with an edge thickness of 17 mm. A new U.S. penny is 1.5 mm thick, so it takes a stack of 12 of them to top this lens by just one millimeter. Comparing a lens like this with a 1.74 lens with AR and of the same power and diameter makes a striking demonstration of how the same Rx can be filled in more than one way.

Within the ophthalmic industry, frame manufacturers work hard to produce attractive and functional frames. Lens manufacturers stress thinner, flatter lenses and have long offered PALs to create a more appealing look. Ultimately, the doctor who writes the Rx and does the post-exam consultation, the optician who fills the lens Rx and the patient must work together to make decisions that lead to great looking eyewear.

Most consumers with new lens prescriptions are eager, or perhaps anxious, to do what they consider “the rest of the job”—selecting a frame. Within the profession, we know that selecting the frame is important for both anatomical and mechanical reasons, while consumers are often focused on cost, comfort and cosmetic issues. Consumers assume that the prescription will look and perform the same no matter how it is filled, and they have little understanding of how both frame and lens design can affect performance and appearance.

MOST LENSES LOOK ALIKE

Lenses come in different shapes and even different colors, but when the public thinks about spectacle lenses, they really know little more than “most lenses look alike.” If pressed, they may recall that some lenses are tinted. In fact, most of the people who depend on you to design their lenses may be satisfied as far as lens appearance goes if their lenses look similar to most other commonly seen lenses. Especially in the mid-power ranges, there are many patients with “good enough” attitudes toward the appearance of their lens, who would be very appreciative of improved lens appearance if they knew that was an option.

We all know that the frame does much more than function as trim, but let’s first consider the “engines” that help us see. Lenses are the light benders that improve visual performance, so we must consider the factors that make anyone feel that their lenses are either particularly attractive or unattractive. These attributes include edge thickness, center thickness, curvature, magnifying, minifying, reflections, edge finish and tint.

EDGE THICKNESS

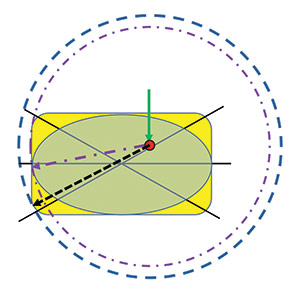

Figure 1

An oval lens shape is superimposed over a rectangular lens shape. The red dot is both the optical center of the lens and the MRP. It is decentered upward and inward for this right lens. The crossing of the black, horizontal and diagonal lines is the location of the geometric center of both lens shapes. If the rectangular shape is used, the blue broken circle represents the lens blank that will be needed, and the blue arrow is the radius of the needed blank for the rectangular shape. It points toward the thickest point of the lens edge for minus powers, and if the power is high, that edge will be very thick. If the lens is a plus power, the thinnest point of the edge is indicated by the blue arrow, and the size of the lens blank will be large which causes the center thickness to be substantial in higher plus powers. If the oval shape is used, the rust circle represents the needed lens blank, and the rust arrow indicates the thickest point of the edge for a minus power and the thinnest point on the edge for a plus power. The smaller lens blank will yield a thinner, better looking lens in midrange and higher Rxs in plus or minus powers. If the Rx is -6.00DS OU and the patient’s anatomy and the frame design requires the placement of the Major Reference Point (shown by the red dot) to be decentered upward and inward. The frame stylist and the patient feel that both the rectangular lens shape (shown in yellow) and the oval lens shape (green) are cosmetically acceptable. The Rx is single vision, so if the MRP height is not specified the lab will place the OC at the mounting line (i.e., halfway from the top to the bottom of the lens) giving the patient unwanted BU prism. If the MRP is specified higher the lens will perform better, but the outer and lower edges of the lens will be thicker for both the oval and rectangular shapes. It makes sense to favor the oval shape, because the thick corners of the rectangular shape will be eliminated, regardless of the MRP placement.

For minus lenses, the further the distance from the optical center to the edge of the lens, the greater the edge thickness will be. That’s a basic fact recognized by all ECPs, but it is easy to neglect comparing the patient’s largest monocular PD with the monocular PDs of the frame. If one or both of your patient’s monocular PDs is more than 3 mm smaller than the frame’s monocular PDs, you are risking needlessly thick lateral lens edges.

If you are fitting a rectangular eyewire with strong minus lenses, you will exaggerate already thick edges. This is because the lens areas at the upper and lower corners of the lens will be even further from the optical centers of the lenses. These areas are seldom used for vision. If you use a more rounded or oval lens, you will be bringing the most peripheral, and what would otherwise be the thickest edges of the lens, closer to the Optical Center (OC), and therefore the edges will be thinner (Fig. 1).

Hyperopic patients can also have issues with edge thickness. Children typically have smaller eye sizes, and if a 70 mm uncut blank is used for a +4.00 Rx, the center and edges are going to be thick, and the child will be wearing needlessly heavy lenses with excessive magnification. By specifying a minimum edge thickness for plus lenses, your lab will surface them to give a better outcome. The other situation that leads to thick edges on plus lenses tends to happen when the eye size is large and the decentration is too great. Excessive inset shortens the distance from the OC to the nasal edge and the edge in that area will be abnormally thick.

MAGNIFYING/MINIFYING

Minus lenses tend to make the eyes look smaller, and in the higher power ranges the Base Out prism in the lateral periphery causes facial inset, which is certainly a cosmetic distortion that emphasizes the strength of the lenses. Plus lenses magnify, and especially for eyes that are somewhat exophthalmic, the effect may not be appealing. A facial displacement outward with higher plus powers can also occur.

The apparent increase or decrease in the area of the face covered by the lenses depends on three factors you can control to some extent and to one factor that you cannot (i.e., the lens power, which must be as prescribed). The other factors controlling magnification or minification of the lenses are: 1. The curvature of the front surface, the lens thickness and the vertex distance. A more convex front surface increases magnification while a more concave does the opposite, 2. The index of the lens material, which tends to reduce both magnification and minification when increased, and 3. The vertex distance. The shorter the vertex distance, the less obvious these magnifying or minifying effects become, and increasing the vertex does quite the opposite.

Fitting a frame with the shortest vertex distance, the smallest practical eye size and the least decentration will decrease both the “big eyes” effects of plus lenses and the “beady eyes” effects of minus lenses. Using lens designs with flatter aspheric base curves and reduced center thickness also minimizes magnification in plus lenses and reduces edge thickness and minification in minus.

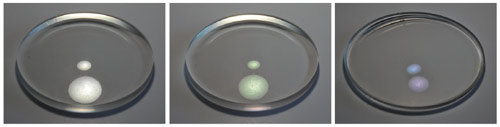

A glowing spherical target is held about 15 inches above the lens surfaces. The lenses are all minus powered so the larger reflections on each one are from the flatter front surfaces, and the smaller are from the more steeply curved back surfaces. The lens on the right is a non-AR lens, the center lens has an AR with a greenish hue, and the left lens has an AR with a blue-toned hue. Because our retinal sensitivity is higher in the yellow-green range, ARs of this color are more obvious, while those that reflect toward the blue end of the spectrum appear more muted. The glowing light source is a golf ball size Styrofoam sphere available from florists and craft stores. Just use a pencil to punch a hole in the sphere and insert a penlight or transilluminator to comparatively demo or evaluate the color of the AR products you prescribe.

Lenses provided courtesy of Walman Optical

The “bullseye” images of minus lenses are the result of internal lens reflection from the wide beveled edges of stronger minus lenses, and these rings tend to call attention to the lenses and make them look stronger. Front surface reflections can hide your eyes and detract from your appearance. Actors who are playing deranged characters sometimes wear lenses with bullseye rings and flat front curves. The film makers then deliberately use shots in which the character’s eyes are blocked by strong reflections. Because the rings are the result of multiple internal lens reflections, AR lenses can help, as can a light tint since the light producing the rings is passed through the tint multiple times. A roll-and-polish edge finish also can reduce the ring effect.

A good quality anti-reflective treatment is like taking the lens away and leaving the prescription in place, and this effect for those looking at the lenses is mostly due to reduced front and back surface reflections. Anti-reflective technology improves the performance of every prescription and every lens material. Used properly, it not only makes lenses less visible, it can also make them more attractive. A lens that is less visible (i.e., clearer) equates with improved appearance. Clearer lenses lend to the impression that lenses are thinner and less strong.

Early single wavelength anti-reflective treatments were magenta in color, and though they were not particularly attractive, they certainly looked “different” than standard lenses. As the better-performing multi-wavelength AR products were developed, lenses were often given a peak reflectance in the yellow-green area of the spectrum, a color which is highly visible to observers. They are not very attractive, but perhaps the higher visibility made the public more aware of the product. Using a less conspicuous color could better serve the objective of making the lens less visible. The lenses that use modified AR coatings to reduce High Energy Visible (HEV) light typically have a blue appearance to observers, although some of these products have a yellow-green reflection from the back surface, which rather defeats the objective of making the lens less visible (Fig. 2). The HEV lens with both front and back surfaces blue.)

TINTS

Tints especially in the yellowish range can give a sallow appearance to the complexion and a jaundiced unhealthy look to the whites of the eyes. Dark tints can hide the eyes, and if a farmer catches you trespassing on his fields, it’s best to remove your sunglasses as you explain yourself to him if you want to build trust and confidence. In all seriousness, both tints and reflections can hide the most expressive part of your face—your eyes. It’s a good idea to keep that in mind when you are discussing lenses with members of the clergy, speakers, sales people, counselors and others who have a strong need to communicate at all levels.

A very subtle lens effect that can make narrow PDs less obvious can be created by using a very light tint (pink, tan or even gray depending on the frame and the patient’s complexion) that is darker laterally and which lightens to clear at the MRP location. This effect works best if it is kept subtle. If the gradient tint used in this way is easily observed, it is too dark. The tint in the far lateral part of the lens should be present but not particularly obvious.

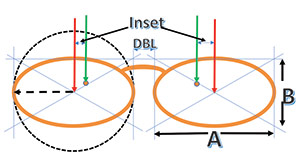

This is a 52□20 frame. The frame PD is the horizontal distance between the two red arrows. It is always the sum of the A measurement and the DBL, in this case it is 72 mm (52□20) making the monocular frame PDs

36 mm (72 ÷ 2). A good rule-of-thumb is to keep the Inset between 1 and 3 mm. This indicates that for higher powers particularly, both of your patient’s monocular PDs should be between 36 and 32 mm if you are using a 52□20 frame. The broken black circle around the right lens demonstrates the smallest lens blank that can be used to fill the frame. The diameter of the circle is marked the ED or Effective Diameter by frame manufacturers. The ED is useful when comparing frames because the frame with the smaller ED is the one that will allow the thinnest edge for minus lenses and the thinnest center for plus lenses. The Inset is the horizontal distance between the geometric centers of the eyewires and the MRPs. When the Inset is kept smaller, lenses will appear to be less strong, and they will weigh less.

Certainly when a lens is thinner, it looks less strong, and that translates easily to it being seen as a more attractive lens. There are several ways to make a lens thinner:

1. Place the MRP (or Fitting Cross) closer to the geometric center of the lens. A good general rule is to select a frame with monocular frame PDs that are only slightly larger than either of the patient’s monocular PDs. The height of the MRP or Fitting Cross should be greater than half of the B measurement, but in strong minus lenses, the lower edge may become significantly thicker than the upper edge if the height is much greater than half the B measurement. For plus lenses, MRP or Fitting Cross locations that are considerably above the geometric center of the lenses will cause the upper edge to be excessively thick. Selecting a frame that keeps the fitting cross or MRP closer to the mounting line for stronger powers when you can is a good rule.

2. Reducing the eye size also reduces the thickness and volume of both minus and plus lenses. In order to keep the eyewear cosmetically pleasing, the frame should be about as wide as the patient’s face. As a result, if the A measurement is to be minimized, you may wish to use a frame with adjustable pads and an increased DBL.

3. It’s good practice to always specify a minimum edge thickness when ordering plus lenses. Using a minimal edge thickness will minimize the magnification and the perceived strength of the lens. Grooved lenses are a special case, and your lab can give you guidelines for the minimum edge thickness of grooved lenses, which require more overall thickness for practical purposes.

4. Using aspheric lenses reduces thickness and volume. The technology for this is well developed. Today’s digitally produced aspheric lens generally have the optimal base curves for both of the major meridians (i.e., they are atoric). This gives not only a thinner flatter lens, but it can make the “sweet spot” larger. Patients with about two diopters or more of cylinder are the ones who benefit the most by atoricity.

5. Increasing the index of the lens material, unlike the above four methods of lens thinning, tends to decrease lens performance because of increased reflectance and increased chromatic aberration. Often the thinning effect of increasing index in terms of benefits is not well understood (Table 1). Whether or not an index change will be significant or even perceptible, change for your patient is an important consideration. Also, the reflectance increases significantly with index increases, and Abbe values also tend to increase index increases. Of course, the reflectance can be effectively controlled by using anti-reflective lenses.

6. By moving the apex of the bevel back from the front lens surface (sometimes called a “1/3rd/2/3rd bevel) can create the appearance of a thinner lens, but this will only work with minus lenses.

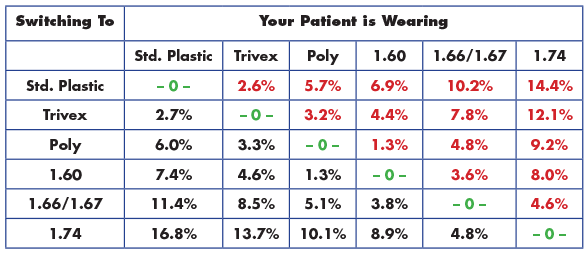

Table 1. Your Guide For Changing the Index

Thinner lenses appear less strong. When the index of a lens is lowered, its volume increases. If the index is raised, the volume decreases. Changing volume also changes lens appearance. For minus lenses, the Table shows the percent the maximum edge thickness changes when a lens is replaced by another lens of the same power, design, shape, decentration and center thickness. For plus lenses, the percentages indicate center thickness changes when a lens is replaced by another lens of the same power, design, shape, decentration and minimum edge thickness. Red percentages indicate increased thickness and black percentages indicate decreased thicknesses.

Examples: If your patient has minus lenses in standard plastic, when made of 1.66, the edges would be about 11.4 percent thinner if the lens was the same shape and center thickness. A – 6.00 lens in standard plastic with a 5 mm maximum edge thickness will be reduced by 6.0 percent to 4.7 mm using poly, and if the center thickness is reduced by .5 mm, the maximum edge would be 4.2 mm. If his lenses were plus powered, and he went from a 1.60 material to standard plastic the center thickness of his lenses would be about 6.9 percent thicker if they were the same shape and lens design. Although this table represents approximate changes for powers between + and – 10.00, the percentages do not represent weight or magnification changes.

Seen from above the right lens (shown on the left) is standard plastic, with a power of –6.00 lens has a standard bevel. It will appear thicker, especially seen from the side, than the left lens, which has the same power, decentration, center thickness and material. The difference is due to the roll-and-polish edge finish of the left lens (shown on the right). This gives more clearance for the pad arm to be adjusted and reduces the edge thickness all the way around. Note the slight protrusion of the front surface of the right lens which is no longer present after the roll-and-polish. Also, the turnback temple design preserves needed overall width of the eyewear while allowing a smaller A measurement and reduced decentration thinner edges—both of which reduce edge thickness.

Frame and lenses provided courtesy of Walman Optical

Edge finish for minus lenses has a direct bearing on lens appearance because the most exposed and thickest edge of most finished minus lenses is lateral and is easily seen when the wearer is viewed in profile. The most effective ways of dealing with the thick lateral edges are:

1. Use the smallest practical eye size.

2. Avoid rectangular lens shapes and favor those that are more oval or rounded.

3. Select frames that will require no more than 1 to 3 mm of decentration in either eye.

4. Ask your lab to move the apex of the bevel of stronger minus lenses back so that some of the edge actually shows in front (“1/3rd/2/3rd bevel).

5. Request a roll and polish edge finish. This actually removes lens material from the posterior edge so that it curves inward instead of jutting straight back.

6. Select a frame with a very dark color, and ask the lab to roll the edge and apply a similarly dark enamel to the area of the lens that fall behind the front if they can supply that service. Edge tinting can be done, but the lens material may not absorb the tint well, and some reports indicate that edge tints tend to fade with time and may need to be re-applied.

LENS SHAPE

Lens shape has a significant effect on lens appearance. The thickest point of rectangular-shaped minus lenses tends to be the lateral corners. When a rounded or oval-shaped lens is fitted, those thickest points are eliminated. This improves appearance and eliminates areas of the lens that are not much used for vision.

The thinnest point of a plus lens is the point furthest from the optical center. Your lab must use that point as their surfacing landmark to be sure the lens will have sufficient lens thickness for edging.

The bullseye rings of high myopia are actually the reflections of the inner surfaces of the lens edges that are repeatedly imaged by light bouncing between the lens surfaces. A rectangular lens shape will have the shape of a wide ribbon that is even wider at the top and bottom, while an oval lens shape will be widest at the point most distant from the optical center, and which becomes much thinner above and below that point. This narrowing makes the bullseye rings less apparent if a lens with an oval shape is used.

Although extremely high prescriptions are needed by a relatively small percentage of the population, the need is there and so is the technology to provide the best possible outcomes. This is a high minus lenticular design with a -25.00 back surface aperture or Rx portion of the lens. The front surface of the lens is +0.50, and the back surface of the carrier portion is +6.00. The diameter of the aperture will vary according to the power prescribed. The large oval reflection is from the front surface of the lens, and the tiny “dot” reflection within the aperture is due to the extremely short radius of the back surface of the aperture. Lenticular designs are available for both high plus and high minus powers. They reduce both weight and improve appearance. Of course, the fitting vertex is extremely critical, so you must work very carefully to get the optimal positioning of such lenses.

This lens was produced and made available for publication through the courtesy of the Rx Specialty Labs Vision Care,

Business Group of Carl Zeiss Vision Inc.

The amount of light reflected from the surface of a lens is a function of the index of the lens. Reflections from a lens surface only appear brighter if the lens is tinted, because the tint tends to obscure whatever is on the other side of the lens. In theory, the bullseye rings of high myopia become less distinct with each reflection when a light tint is used. From a practical standpoint, the tint also darkens what is seen through the lens, so the overall effect of reducing the appearance of those rings is not much affected except with very dark tints.

In general lens tints do little to improve the appearance of the lens itself unless the patient wants the dramatic look of a bright flash-tint.

Even though you have the best intentions in the frame selection area, the relationship will tend to be one of buyer/seller. This can make it difficult to achieve the patient’s understanding of eyewear options and add-ons. Upon leaving the exam room, the relationship of doctor-patient quickly shifts. If you are a dispenser who works in an office that provides examinations, you might encourage the doctors to at least mention lens technologies that could make the new prescription look and perform better. These options can include careful frame selection, using a more appropriate lens material, having the prescription filled with a better lens design and using AR lenses rather than standard lenses, are topics that can be explained in the frame selection area after the doctor has touched on the ones that would be most relevant. ■

BASIC TOOLS FOR A LENS ‘FASHION SHOW’

- An uncut minus lens blank to demonstrate to patients how making a minus lens smaller will reduce edge thickness. A -6.00 in standard plastic and with a 70 mm diameter makes a memorable demonstration.

- A set of six sample lenses in 1.49, Trivex, Poly, 1.60, 1.66/1.67, 1.74 in standard lens form all in the same power so that you can show how lens thickness changes when the lens material is changed.

- Sample lenses of each of the anti-reflective lenses you prefer to prescribe, along with a sample standard lens of the same material can let your patient see how AR lenses perform better.

- Dedicate a dozen or so slots on one of your frame display racks to a selection of frames glazed with AR plano lenses, so the improved appearance can be easily pointed out.

Contributing editor Palmer R. Cook, OD, is an optometric educator and optical dispensing expert.