Sponsored by IOT

By Deborah Kotob, ABOM

IOT Intelligence is the technology and innovation that powers the Camber lens excellence, from the unique variable curve front surface of the Camber blank to the strict lab enablement process.

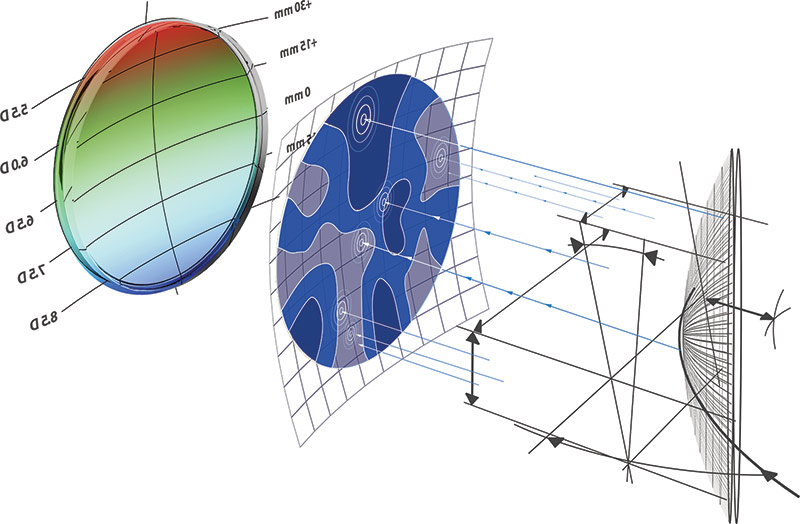

Let’s review the many technologies that result in the unique Camber lens. Camber Variable Base Curve: The Camber variable base curve blank improves the front surface profile that delivers each viewing zone a base curve matched to its function. The width of undistorted near vision is a major improvement over single vision front freeform progressive designs.

IOT Digital Ray-Path 2 Technology: IOT Digital Ray-Path 2 is an advanced ray-trace technology that calculates the lens position relative to the eye for all gaze angles. With the breakthrough IOT Digital Ray-Path 2 Technology, IOT formulated a new method of calculating the optimal lens surface to produce accurate power for all gaze directions and object distance ranges in the accommodative space. The result—customized lenses with superior compensation of oblique errors for broader, clearer fields of view and stable images.

Steady Plus Methodology: The Steady Plus Methodology is only available with Camber lenses. The gradual increase of power from the top to the bottom of a progressive lens leads to defocus in the peripheral areas of the lens. It is attributable to sphero-cylindrical power error inherent on either side of the progressive corridor. It is not possible to develop a progressive lens with zero peripheral distortion due to geometrical limitations, as explained by the Minkwitz Theorem.

However, Steady Plus Methodology improves on past efforts that only reduced lateral distortions by minimizing the cylindrical component of the sphero-cylindrical error. The progressive lens designer’s goal is to minimize these distortions to their geometrical limits. With Steady Plus Methodology, both the mean power (spherical) and the cylinder power errors are minimized. The technology employs new mathematical methods to compute the best lens topography to achieve the least distortion and swim effect, while providing superior image stability without a reduction in progressive lens optical performance. The wearer experiences binocular symmetry (equivalency) in the near zones.

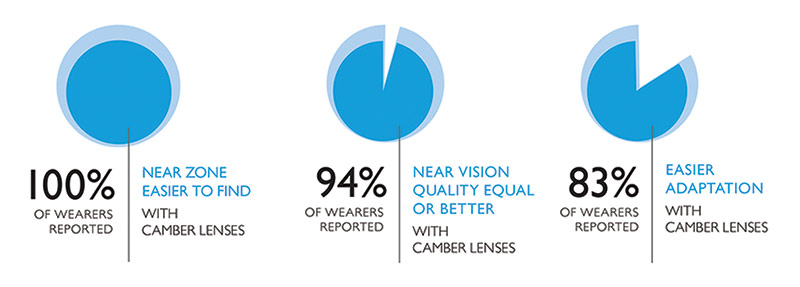

What do wearers have to say about Camber lenses? In a double-blind study, test wearers compared the same progressive design, one of them engineered with Camber Technology, and the other without it. Proven results: In the wearer trial, 100 percent of wearers reported near vision easier to find with Camber lenses. Wearers perceived improved peripheral vision and wider visual fields.

Test wearers wore each pair of glasses for the duration of one week but were not aware of which lenses they were wearing for the entirety of the study. Both pairs of lenses were of identical material and base curve and mounted in the same frame. Wearers were surveyed about their experience with the lenses after testing them both.

Rigorous Lab Enablement Process: From start to finish, excellence is the priority. A rigorous lab enablement process ensures excellence in every step of the manufacturing of the final Camber lens, personalized for the patient. Why do Camber lenses require a special enablement process? Only qualified laboratories may purchase Camber lens blanks and offer Camber lens designs. Manufacturing dual-sided lenses requires unique process control measures. The enablement process ensures your laboratory is providing lenses with excellent optical performance. The lab enablement process will improve the overall quality of the lenses produced by the lab.

A digitally optimized and individualized back surface: The Camber variable base curve lens blank combined with IOT Digital Ray-Path 2 Technology and Steady Plus Methodology works synergistically to expand the Rx range, minimize swim effect, provide better cosmetics (flatter), improve binocular vision in the intermediate and near zones, and increase distance fields of view. To produce Camber prescription lenses, cutting files are optimized using IOT Digital Ray-Path 2 Technology and Steady Plus Methodology to trace, analyze and compute surface profile across the lens to best accommodate the prescription and frame/fit parameters and minimize lateral and oblique aberrations. All of this technology leads to the personalized lens enabled through a rigorous lab enablement process so that the Camber lens wearer experience is outstanding, surpassing all prior experiences.