In my last Opticians Handbook article, I traced the lineage of American Optical Progressive lenses and examined how those designs progressed over time this second article highlights the AO bifocals. Below are the early to mid-20th Century glass bifocal designs and includes information and excerpts from various AO catalogs.

Early 20th Century AO Glass Bifocals

Cemented wafers (Glass)

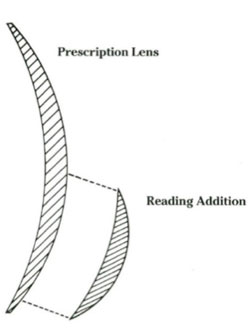

When setting up the Museum display, I realized the logical first bifocal example would that of the cemented wafer. This method to produce a bifocal was common at the turn of the 20th Century. The bifocal was produced by cementing the segment wafer or "add" onto the single vision "distance" lens.

Ben Franklin is credited with inventing this concept for what was to be the AO Executive style design discussed later in this article. Cementing the add power onto the lens became a practical early method to produce bifocals, and was introduced by AO in the mid-1880s. The lens and reading addition illustration here demonstrates how wafers were literally added to the base prescription lens to produce a bifocal. The "addition power" was actually cemented as shown and is why we call it the add power.

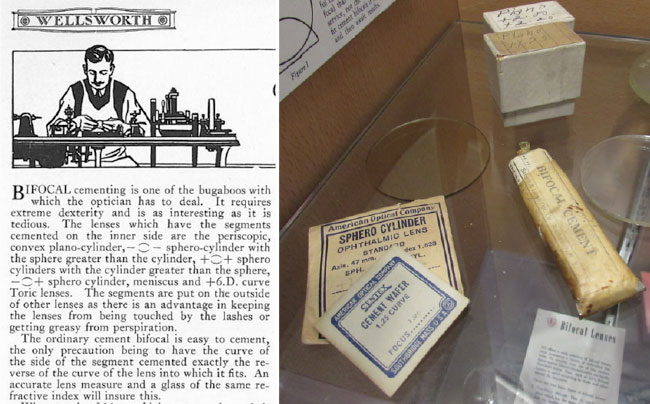

It was not until early in the 20th Century that bifocal manufacturing processes would be developed sufficiently to replace cementing as the primary means of manufacturing bifocals. An excerpt from a 1919 AO article describes some of this process. AO catalogs from 1935 still included wafers as a product sold, which demonstrates this process was still in use even at that late date.

AO 1919 article on cementing bifocals, left, and OHM Display with tube of cement, right.

Early in the 20th Century, American Optical's bifocal product lines expanded with improved design along with process improvements to produce them. Two methods of manufacturing glass bifocals were employed involving either the "one piece" or "fused glass bifocal" methods.

The following explanations of both glass bifocal types are excerpted from an AO lens catalog:

- One piece glass bifocal: Made from glass which is the same density throughout. Its double focus is governed by differences in curvature between segment and major.

- Fused glass bifocal: Manufactured from two pieces of glass of different density, which are fused together. Glass in the reading segment has a higher index of refraction to provide additional plus power.

The image below, from the Optical Heritage Museum artifacts, illustrates how AO fused glass bifocals/trifocals were made using glass of differing densities as noted above.

In the second decade of the 20th Century, two significant products were released. Both introductions had been delayed due to patent litigation on either the design or the process to manufacture them.

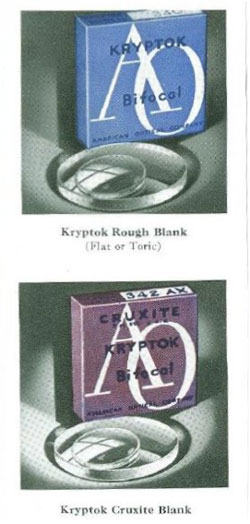

Kryptok

The AO Kryptok lens was a one-piece design where the segment was on the front and utilized 4 base curves—4.00, 6.00, 8.00 and 10.00. The Kryptok lens was described as having "the bifocal side being factory finished on automatic machines and has a surface which cannot be improved upon except through pitch polish." In a 1935 catalog, they were described as follows: American Optical was a pioneer maker of the Kryptok—one of the first improved bifocals. Though today outclassed by new developments, American Optical Kryptoks are the highest standard of Kryptok excellence.

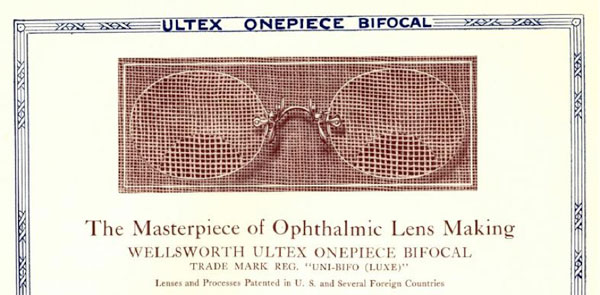

Ultex

The AO version of the Ultex lens was released in 1917 after patent litigation and licensing terms were agreed upon. This took almost a decade to resolve before this release. The Ultex was a one piece bifocal with the segment located on the concave, rather than the convex side. This meant that all cylinder curves needed to be ground on the front of the lens.

An AO product catalog summarized the AO Ultex as follows: "American Optical Company originated and patented certain superior methods of manufacture that produce highest quality Ultex Lenses. Because they are made from one piece of hard crown glass, which will not scratch, and because it is color free, Ultex is one of the most popular bifocals made today."

The Ultex one piece bifocal had a segment shape provided in either a round or crescent geometry. The advantage of the bifocal location on the concave surface was promoted as follows: "The reading segment, being ground on the concave side, is less visible to the observer and protected from injury. The lenses can be ground extremely thin, in fact just as thin as the single focus lens could be ground."

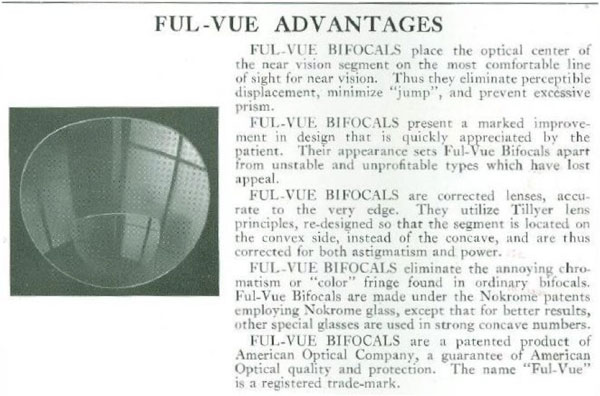

Tillyer Ful-Vue Bifocal Patent – 1925

In 1925 AO Patented the Tillyer Ful-Vue Bifocal. It was designed by "Doc" Edgar Tillyer who was AO's most famous scientists. For more info on Doc,

see my website link.

The segment shape was much like future "curve top" designs and its features are described here:

Panoptik Bifocal Patent

AO introduced the Panoptik bifocal lens, sold under license only, in 1929. It, like the Fulvue was a fused glass bifocal. In a 1963 AO catalog, name was still used as it shows the Tillyer Panoptik being sold, along with many other Tillyer glass bifocals designs.

Numerous AO Bifocal Glass Designs Emerge

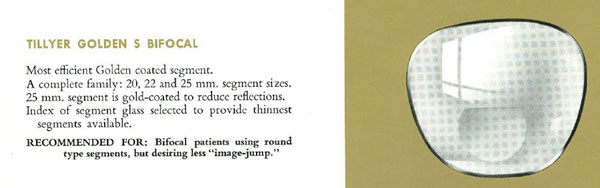

The catalogs during the 30's thru the 1970s show a large assortment of fused glass bifocal designs with a variety of segment shapes and sizes. During this period, a majority of AO glass bifocals introduced were fused rather than one piece products.

An added feature promoted by AO during this period for glass bifocals, included real gold coating on the top of the segment ledge to reduce reflections, as well as promote as a high quality lens. An example from a 1963 catalog is shown below:

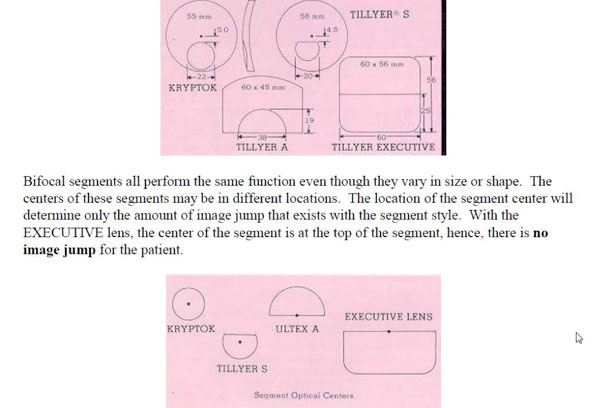

AO Executive – Glass Manufacturing Production from 1952 to 2005 in Southbridge

The Ben Franklin design bifocal was not actually manufactured in mass until American Optical introduced this design as a "one piece" product in 1952. It proved to be one of AO's most successful glass bifocal products. The Executive was AO's longest running product line, and was only recently discontinued in 2005 when the production line was shut down after 53 years of continuous production!

Aside from a full reading area for the Executive lens, a feature that was also heavily promoted was that the wearer experienced no image jump as described below. This was not the case for many other bifocal designs.

The most famous person known to have ordered the AO Glass Executive product was President Kennedy. Unfortunately, as described on this link of my website, AO received an order for 3 pair of 1 Add Glass Execs for the President on the day was assassinated - November 22, 1963

Other American Optical Hard Resin (AOLITE) Designs

I would be remiss to not acknowledge the variety of plastic lens bifocal designs designed and manufactured by AO. Given the length of this article, I will not detail them all here, but many are on display at the Museum. AO was a pioneer in producing plastic lenses in the 1950s, and my father Donald Whitney was Plant Manager for producing AO's plastic lenses in those early days. His 1975 overview of AO's AOLITE Division is

posted here and mentions a few of the plastic bifocals produced.

Since plastic lenses are of one de / density /refractive index, all such bifocals are "one piece" and rely on differing curves rather than materials to produce the addition power.

AO Blended Bifocal - 1978

One pre-AO PAL plastic bifocal that is also on display was first produced in 1978 and called the Blended Bifocal. This lens had a round segment which was produced by using a series of blended zones of differing curvatures to change the power gradually to produce a no line bifocal. This product, while crude by today's standards, was sold for decades by AO.

I hope this look back at early bifocals was of interest, and hope some of you will be able to visit the Museum in Southbridge. For those who cannot, please visit our website or like us on Facebook.