In-Office Lens Fabrication: It Makes Sense

By Mark Mattison-Shupnick, ABOM

Release Date: August 1, 2013

Expiration Date: December 31, 2017

Learning Objectives:

Upon completion of this course, the participant should be able to:

- Understand the opportunities provided by in-office lens fabrication.

- Learn about the technology and process using the unique QSpex lens fabrication system.

- Understand why private label has become an optical industry advantage.

- Determine whether in-office lens fabrication would be of interest in your office.

Faculty/Editorial Board:

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Course STJHI083-1

THIS COURSE IS SUPPORTED BY AN EDUCATIONAL GRANT FROM Q-SPEX TECHNOLOGIES

I’ve spent a couple of months since Vision Expo East 2013 thinking about the opportunity and feasibility of in-office lens-making, where I had a firsthand look at the QSpex technology. Now I’m a strong proponent of in-office lens finishing, i.e., the edging and glazing of lenses ordered uncut (not edged into the frame) from a lab. In fact, I work for an independent optician in which I often use the three edgers upstairs in their finishing lab. Here, I’m talking about actual fabrication (casting) of an AR, polarized or photochromic lens in your own office, neither at the lab nor the manufacturer.

What is it about in-office lens fabrication that could make it a good decision for you? It’s been tried before. We’ve been moving to on-demand lens designing (digital) for frame and fit, thinner and lighter lens materials for more than half the lenses sold and for many offices, AR lenses have become more than half of all lenses delivered. Why could in-office lens fabrication be a renewed opportunity now?

SOME OF THE PEOPLE, SOME OF THE TIME

All practices manage a toolbox of products that meet their patient’s requirements for good, better and best. We consistently add and delete new products from the toolbox each year. I suggest that in-office lens fabrication creates a unique opportunity to manage your office’s lens preferences and reduce the number of choices in the toolbox. Since you can only sell the best of the best a smaller percentage of the time, what should your lens platform be?

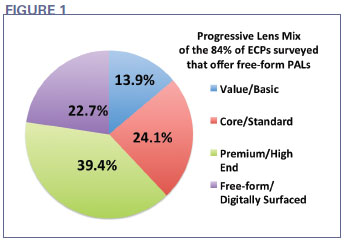

For 2012, from The Vision Council, when asked about progressive lens mix, 84 percent of the ECPs surveyed were offering free-form lenses (Fig. 1). Of those 84 percent, about 23 percent were free-form or digitally surfaced lenses. The rest were made up of high-end to value lenses with the majority in the premium high-end category (~39 percent). As a result, this suggests that free-form sales, which in itself is a mixture of good, better and best is only approaching a fifth of all lenses sold (only 84 percent reported so that means 0.84 x 22.7 percent or about 19 percent are freeform). That also shows that the vast majority of offices make up the balance (just over half) of their mix using more traditional lenses. The question then becomes, as technology and market pressures shift, what should those lenses be?

One option is to make your own lenses and participate in the growing phenomenon of private label. Private label uses the equity of patient trust that you have built. Why not deliver a lens that is your own brand as long as it also delivers technological upgrades and the product combinations that answer to the patients’ budgets, managed vision care coverage and your targeted office margins?

Why is private label an opportunity right now? Private label digital lenses are a growing market amongst laboratories. According to L&T Group Editor Andy Karp: “Although there are no reliable statistics on the size or rate of growth of private label digital progressive lenses, knowledgeable industry observers peg the market at anywhere from 2 percent to 5 percent of total progressive lens sales, and some believe it could be more than double in the next year or two. New data shows that digital PALs are gaining in popularity. Sales of these lenses rose more than 15 percent during 2012 according to VisionWatch, the large scale, continuous research study conducted by The Vision Council. Anecdotal evidence from suppliers indicates that sales of private label digital PALs are contributing significantly toward this upward trend.”

This suggests that in-office lens fabrication can provide that same private label opportunity to separate you from the competition and deliver the margins and success needed to justify changing product and office procedures.

There is only one lens-making system newly available, and it has changed from the earlier glass mold, urethane gasket and awkward coatings systems to one of disposable AR, polarized, photochromic (available this year) and HC to lens transferring molds using a preattached spacer. If the majority of lenses required in your office are premium but not digitally personalized, then what should they be?

ANOTHER LOOK AT QSPEX

Instead of ordering lenses from the traditional laboratory, this lens fabrication system produces a lens to prescription inoffice. The process requires molds to produce the front and back lens base curve and powers, the pre-attached spacer holds the molds together, monomer, and the filling and curing unit.

Molds: The QSpex System utilizes single use plastic disposable molds, eliminating the need to clean the molds after use; they are simply thrown away or recycled. Molds are ordered or inventoried clean and sealed. In the past, mold inventories were expensive and required that office technicians become excellent at mold cleaning after each use, since anything on the mold would be transferred to the lens. In addition, because molds were used repeatedly without proper handling, the molds would often become damaged and need to be replaced. That was expensive and created operator morale problems.

In this system, there is no repeat use of molds but are instead disposable (Fig. 2). This ensures that each new lens made starts with a new mold, which provides three benefits. First, it eliminates the need for cleaning expertise. Second, there isn’t an expensive mold investment to replace if damaged and lastly, lens design improvements can be implemented as each new lens is made because molds are received new each time. In the past, a mold inventory limited changes to new designs since mold inventories were owned and used over and over again. This is analogous to the advantage for manufacturers in freeform surfacing where any variety of progressive designs can be made from a single vision lens blank.

Spacers: No gaskets per se are required since each back mold is supplied with a pre-attached spacer. This spacer also provides an axis alignment protractor for compound and polarized lenses. In traditional casting, gaskets hold glass molds a predetermined center or edge thickness apart. Again, in previous systems, gasket inventories were pre-manufactured and specific to the lens material and power being made. For plus lenses in rimless and semi-rimless frames, an additional spacer may be required to produce a slightly thicker lens edge to ensure that there is enough strap or grooving thickness.

Filling Station: An individual “tottle” (softsided bottle) of monomer is placed in a small filling station and tube affixed through the spacer to fill the lens cavity.

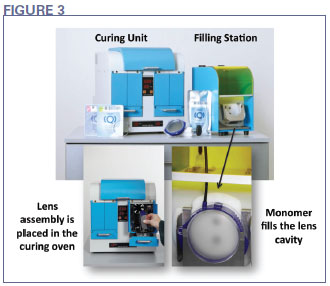

Tabletop Unit: The last part of the system is a small footprint Curing Oven that houses the right and left mold chambers and a separate annealing unit (Fig. 3). The footprint of the curing unit is 14 inches wide, 12 inches long and 13 inches high. The filling unit is 6 inches wide, 7 inches long and 8 inches high. Both the curing and filling unit can sit on top of the mold storage cabinet which is 36 inches wide, 25 inches long and 38 inches high. The mold storage cabinet is on castors and can be easily moved to any location.

Time: The process to produce a pair of lenses ready for edging is under 45 minutes, including hands-on assembly and curing/annealing times.

CONTEMPORARY LENS PROPERTIES AND OPTIONS

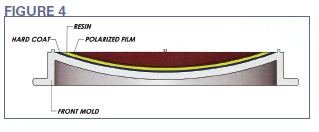

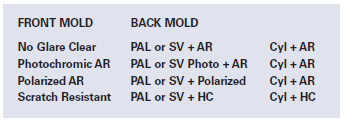

Other impediments to in-office lens casting in the past were that there were limitations in prescription range, lack of AR, photochromics and polarized lenses, or combinations of them. In this new system, the front molds are prepared so that they will transfer lens treatments during the lens curing process. This means that the QSpex System produces either PALs or single vision lenses as non-glare AR, photochromic with AR or polarized lenses with back surface AR. This is determined by the front mold treatment selected. A front mold that creates a polarized lens would look like Fig. 4. The back mold would add AR if selected that way.

LENS OPTIONS

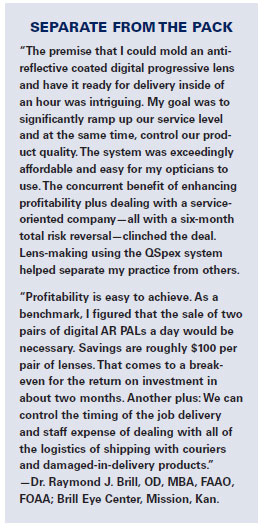

Like in-office finishing, your office controls quality, patient service and costs. Unique to this system is the way that molds are packaged so they deliver an uncontaminated surface for the fabrication of quality AR lenses. The package is sealed to the environment until needed. “In-office lens production time is typically an improvement when compared to an outside lab—and to less than an hour when required—plus the cost of goods can be reduced by about a third, even when considering the fullyweighted internal labor costs,” says Raymond Brill, OD.

LENS PROPERTIES

A prescription range of -4.25D to +2.00D

with cylinder to -2.00D with progressive

adds of +1.00D to +3.00D in 0.25D steps

covers about 86 percent of contemporary

prescriptions. The combined properties of a

1.55 index (1.547 actual value), specific

gravity of 1.15 grams per cubic centimeter

and an Abbe value of 40 produce thin, light

and visually clear lenses over the

entire available prescription range.

A prescription range of -4.25D to +2.00D

with cylinder to -2.00D with progressive

adds of +1.00D to +3.00D in 0.25D steps

covers about 86 percent of contemporary

prescriptions. The combined properties of a

1.55 index (1.547 actual value), specific

gravity of 1.15 grams per cubic centimeter

and an Abbe value of 40 produce thin, light

and visually clear lenses over the

entire available prescription range.

This lens material can be drilled, notched and grooved, and can be edged with any edger. Since the QSpex lenses, at equivalent center thicknesses, are more impact resistant than standard hard resin, minus lenses have thinner centers in the powers that matter, above -2.00 diopters. In addition, consistent with modern lens materials, these lenses are 100-percent UVA and UVB blocking.

NEW PLATFORM, REDUCED EMPLOYEE STRESS

If you’ve considered the addition of new lens products in your office, you’ve learned that when a product does not have the full complement of availability in range and/or treatments, opticians avoid them. It’s difficult to know when to offer them and if offered but not available, the patient has to be called. As a result, it is critical that any new lens or lens platform provide options for the majority of patients the majority of the time. Considering thinness (index), lightness (specific gravity), impact resistance and treatments available, this becomes an option for an office’s core lens offering. It is unlike switching to 1.67, for example, for all patients. Most offices wouldn’t sell 1.67 high index lenses for a -1.00 prescription in a standardsized frame. There is less benefit for the increased costs. However, if lens fabricating provides merchandising and margin opportunities as well, it’s well worth considering.

Just like the way that free-form is used by your lab as a manufacturing method to introduce new technologies, broaden the treatments available in the same designs and reduce the costs of fixed design lens blanks in inventory, lens fabricating can do the same for the professional office and reduce dependence on the laboratory. Offices implementing the QSpex System can create their own business opportunities.

Lens fabrication is an alternative that delivers another lens design for your consideration. It is just like a rep visiting to tell you about a new lens you should consider for your business: 1. Test the attributes of the design (it must have all the same attributes or be better). 2. Have the right material platform that delivers patient benefits that are easy to sell, and 3. Have been upgraded to the norm of higher standards, by including AR with every lens.

ADVANTAGES OF PRIVATE LABEL

www.brilleye.com |

Private label lenses make you unique. Your practice name on a progressive takes advantage of the professional equity that you’ve built with customers. They’re not shop-able on the Internet but because they are your own brand, they carry your personal stamp of approval.

Many independent labs have adopted private label digital lenses. In fact, some of the larger legacy lens producers provide private label designs to labs as a business opportunity for all the same reasons you should consider it.

Private label is an effective business strategy. Online reference sources conclude that there are various advantages for the retailers to go for private label brands. The advantages include control over pricing of the product/service. For lens fabricating, higher margins are available when compared to equivalent branded products. Considering that the average eyewear consumer knows few lens brand names and relies on the ECP’s expertise, lens fabricating provides the flexibility to develop an effective pricing strategy. Other advantages are marketing plan flexibility, creation of a personalized image which in turn leads to higher customer loyalty, control of production, marketing, distribution and profits, and the opportunity to meet changing customer preferences, i.e., the acceptability of private label products. Your own progressive lens brand reduces legacy brand name dependence and yields more flexibility, especially when the economy suffers. Finally, when consumers price compare, your brand is only available from you.

WALK THE PLANK OR ELSE

If the doctor/business owner purchases a lens fabrication system, will the opticians mutiny? If you or your doctor agrees with the business argument that the product is a responsible addition or substitution for your office, here’s what is needed to make it work for everyone in the office. New procedures require ownership by the staff that operates them. Therefore, getting everyone on board is essential. In fact, their participation in the decision is preferred.

Initially, there will need to be an allocation of time for the initial setup of the equipment in the office and proper training—just like learning to edge on new equipment. Being good at making lenses without bubbles or defects do take some practice—it’s that simple. In fact, this probably requires fewer technical decisions than edging. That’s a good start. The sophistication built in to the system allows easy adoption; speed and expertise come with time.

KNOW A THING OR TWO ABOUT CASTING

I worked as part of a lens manufacturing company (SOLA) for over 22 years. During that time, my opinion was that casting was too complicated, especially with the requirements for high quality glass molds that cost a lot, the special handling required to clean them without also damaging them and the fact that most times they couldn’t be replaced quickly since we were making so many lens styles, each requiring its own molds in quantity.

Disposable molds that transfer AR to a thinner/lighter product—those are changes that could influence even the skeptic in me. If I were a practice owner, lens fabrication warrants a pencil test (product test and financial opportunity analysis) and a positioning exercise (marketing strategy assessment) to decide whether it’s the right opportunity to change the way in which business is done. The company reports that impact testing is not required since QSpex does the impact compliance testing for each of its accounts in a special sampling program. Information about Impact Compliance can be sourced from The Vision Council (thevisioncouncil.org).

CONCLUSION

In-office lens fabrication creates a unique opportunity to manage your office’s lens preferences and reduce the number of lens choices in the toolbox. Since the core of an office’s lenses is still standard and premium, this creates the potential for a platform shift when the other design, material and treatment options meet the office’s requirements for comparability. That leaves the options of private label and cost of goods/potential margins as an added bonus. Using a unique technology and curing unit, QSpex has created a new opportunity to rediscover the opportunity for in-office lens fabrication.