Photograph by Ned Matura

When creating a pair of eyeglasses, choosing the right lens material for each patient and each frame they wear is as important has having an accurate prescription. In fact, in order to properly fill a prescription, a dispenser must know the lens material options best suited to each patient’s visual requirements and lifestyle needs. Materials help determine thickness, weight, safety, scratch resistance and the suitability of selected mountings.

A primary consideration of dispensing is the selection of a lens material that will best suit the overall function of the finished product. In order to make valid decisions along this line we must understand both the characteristics and general availability of the lens materials at our disposal. If the material meets the need but is not available in the form needed, the job becomes an exercise in futility—patients become frustrated and lose faith in the ability of the practice to handle their needs.

Lens materials fall into several categories.

Glass—The original industry standard that has fallen into infrequent use due to considerations of weight and safety-liability issues. It still makes up around 5 percent of the total usage and will probably remain around indefinitely in that glass has some very unique capabilities. In certain cases glass may be the best choice.

Standard Plastic—Standard 1.50-index plastic lacks the advantages of many of the newer materials, but it is still a good product at the lowest price point the industry has to offer. It is lightweight, tintable, safe and available in more options than any other lens type. Industry-wide, it makes up about 50 percent of all lens sales.

Polycarbonate—The new standard that has grown to about a 35 percent industry usage. It is thin, strong, lightweight, scratch resistant and available in a wide variety of lens options.

New Generation Mid- to High-Index Plastics—This is a broad category that takes in many different indices from 1.53 to 1. This is the growing area that will push polycarbonate higher and plastic to extinction. This family of materials is specific to optical use and therefore best delivers highly desirable qualities such as thin profiles, advanced design for better optics and greater durability. At present this category is at about 10 percent and growing at the expense of the more basic material options. 7.

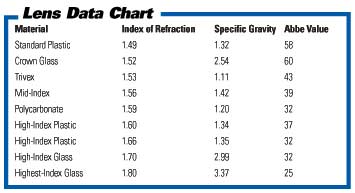

Defining the Terminology

Thickness is defined in terms of Index of Refraction. Index of refraction is a ratio of the speed of light in air compared to the speed of light in the medium. The higher the number the more that material will bend light. Because of its improved efficiency at bending light that material can provide the same prescription value as a lower index (a less efficient light bending medium ) in a thinner profile. All other factors being equal the greater the index of refraction the thinner the lens will be. A polycarbonate lens with an index of 1.59, all other factors being equal, will be thinner than a lower index plastic of a 1.50 index.

Weight is defined in terms of Specific Gravity. Specific Gravity is a measure of physical density expressed in grams per cubic centimeter. In the case of specific gravity the lower the value the lighter the lens. Comparing two equal lenses, one of plastic with a specific gravity of 1.32 and one of polycarbonate with a specific gravity of 1.20—the polycarbonate will weigh less.

Off-axis visual clarity is defined in terms of Abbe Value. Abbe Value is a measure of a lens’ dispersive power. As light passes through a lens farther to the periphery, it becomes scattered so as not to focus each of its components equally on the retina. This dispersion of light into its component parts is known as chromatic aberration and it manifests itself to the wearer as blur. Clinical studies indicate that the point at which chromatic aberration becomes a problem to the average wearer is when the dispersion causes a .25 diopter of prescription error. In order for this error to be noticed, the lenses must be of high power or the eye must stray from the center by approximately 15mm. In reality, while much is made of the effects of lower abbe values, they do not impact normal vision greatly because the eye naturally works in an area no larger than 7mm to either side of the optical center. The lower the abbe the greater the off-axis blur.

Light-controlling lenses are defined in terms of photochromics. Photochromics are lenses that have the ability to lighten and darken in conjunction with the availability of ultraviolet light. In the beginning this quality was limited to glass lenses only; however, this property has been expanded to many of the new generation plastic products. Over the years this option has evolved in efficiency. At first these lenses were never completely clear, not very dark, slow to darken and slower to fade. The product today has overcome virtually all of those problems. The new Transitions lenses move easily and quickly between clear and sun dark. Even in the higher temperatures that stifled older product this new generation material performs with maximum efficiency. The availability of photochromics has expanded to include many lens materials and a great variety of designs. While the product does get sunglass dark it does not darken well behind the windshield as the glass blocks the triggering ultraviolet light. These lenses make a great primary pair and partner well with regular sunwear for driving.

With so many lens materials to choose from, a knowledgable dispenser is certain to find the right one to meet each patient’s visual requirements, lifestyle needs and budget.

A Menu of Lens Material Options

Glass

Thickness: Index 1.523 Standard

Weight: Specific gravity 2.54—Heavy

Safe: This Material Is A Liability Concern

Ultraviolet: In its clear form blocks about 50 percent UV

Abbe: 60 Very Good

Tint: Very Limited/Photochromics Available

Pricing: Average

Manufacturing: Not Standard Any Longer

Comments: Offers good optics. Tainted by liability issues. Not available with aspherics; PALs limited. Not a popular choice.

Standard Plastic

Thickness: Index 1.50 Standard

Weight: Specific gravity 1.32—Average

Safe: Good

Ultraviolet: In its clear form blocks about 50 percent UV

Abbe: 58 Very Good

Tint: No Problem/Photo-chromics Available

Pricing: Average

Manufacturing: Standard

Comments: This material offers good optics, but its usage is dropping since it doesn’t offer a very thin profile. New technology such as aspherics are not generally available.

Mid-Index Plastic

Thickness: Index 1.56

Slightly Thinner

Weight: Specific gravity 1.42—Average

Safe: Good

Ultraviolet: In its clear form blocks about 99 percent UV

Abbe: 36 Good

Tint: No Problem

Pricing: Moderately Above Average

Manufacturing: Standard

Comments: This material offers good optics and a slightly thinner profile. Used in cast lenses. Given a choice it is better than plastic, but falls short of poly on thin and safe, and short as an ultimate thin lens solution like 1.6 and 1.67.

High-Index Plastic 1.6

Thickness: Index 1.60

Same As Poly

Weight: Specific gravity 1.34—Light

Safe: Good

Ultraviolet: In its clear form blocks about 99 percent UV

Abbe: 34 Good

Tint: Limited for Sun Colors /Photochromics Available

Pricing: More than Poly

Manufacturing: Standard

Comments: This material offers good optics, and a notably thinner profile. Same thickness, more expensive than poly. Limited to Single Vision & Progressives. Can be aspheric. A great lens.

High-Index Plastic 1.67

Thickness: Index 1.67

Very Thin

Weight: Specific gravity 1.35—Light

Safe: Good

Ultraviolet: In its clear form blocks about 99 percent UV

Abbe: 34 Good

Tint: Limited for Sun Colors/Photochromics Available

Pricing: Significantly more than Poly

Manufacturing: Standard

Comments: This material offers good optics in a thin lens. Approximately 30 to 35 percent thinner than standard. Limited to Single Vision & Progressives. Is aspheric. A high tensile strength (flexible durability) makes it a great lens for drilled rimless mountings. Like all high index this material should be provided with AR.

High-Index Plastic 1.74

Thickness: Index 1.74

Ultimate in thin

Weight: Specific gravity 1.46—Light

Safe: Good

Ultraviolet: In its clear form blocks about 99 percent UV

Abbe: 33 Good

Pricing: Premium Priced

Manufacturing: Still New/

Not standard ultimate in thin, with aspheric design and AR this lens offers outstanding optics and the best cosmetics in the industry.

Polycarbonate

Thickness: Index 1.59

Weight: Specific gravity 1.20—Light

Safe: Good (Most impact resistant)

Ultraviolet: In its clear form blocks about 99 percent UV

Abbe: 32 Not Really An Impediment To Clarity

Tint: Limited for Sun Colors/ Photochromics Available

Pricing: A Great Value/Less Than High Index

Manufacturing: Has Become A Standard

Comments: This material offers good optics and a notably thinner profile. Availability is excellent in lens styles and base curves. This is a great buffer against liability issues. All in all this lens offers more benefits at the most reasonable price over all other materials.

Trivex

Thickness: Index 1.53 About Same as Plastic

Weight: Specific gravity 1.01—Light

Safe: Good

Ultraviolet: In its clear form blocks about 99 percent UV

Abbe: 43 Good

Tint: Limited for Sun Colors/ Photochromics Available

Pricing: Premium Priced

Manufacturing: Still New/Not standard

Comments: This material is being positioned against poly, but it is thicker than poly, more expensive than poly, limited in availability, as light and safe as poly. The best position for this product is to replace standard plastic. It is a good choice for drilled rimless as its tensile strength resists cracking and breakage.

Summary

When making lens decisions it is important to evaluate the material according to the following industry standards:

Index of refraction—The measure of a lens material’s ability to bend light. This value is a ratio derived by dividing the speed of light inside the material into the speed of light in air. The larger the resulting number/the greater the bending of light/ the thinner the lens.

Specific Gravity—A measure of lens material weight. It is expressed in grams per cubic centimeter. The value is a ratio of its density to that of a standard substance. The lower the resulting number/the less density/the lighter the material.

Abbe value—This is a measure of a material’s tendency to disperse visible light into its component colors. The impact of this value can be a factor in blurred vision in the peripheral areas of a lens. The lower the number/the greater the dispersion.