By Palmer R. Cook, OD

Andy Dufresne walked from the warden’s office to his cell in full view of the prisoners and guards. No one noticed that he was wearing the warden’s expensive and freshly shined shoes. Andy is the main character in Stephen King’s short story, Rita Hayworth and The Shawshank Redemption, and in the movie, “The Shawshank Redemption.” Andy believed that even highly focused observers miss significant details—and he was right.

Unless your dispensary is ordering -12.00 lenses, or something of that ilk, little thought may be given to the finished edges of the lenses. Lay people, however, tend to benchmark the strength of lenses based on, “Oh my, look how thick that poor man’s glasses are!” as they view the eyewear from the side. In the case of high plus powers, the comment might be, “Did you notice how big his eyes look in those glasses, and how red his nose was when he took them off to rub?”

Even when a prescription is not in double digits, there are edge-related factors that can make eyewear cosmetically unacceptable or impossible to wear comfortably. Fortunately, there are many ways of avoiding these pitfalls. Some of these ways probably come to mind easily, and others may be easy to miss, just like Andy Dufresne with the warden’s footwear.

FRAMES

FRAMESFrame selection plays a big role in reducing lens thickness. Both turn-back temples and adjustable nosepads can help (Fig. 1). With adjustable pads, you may increase the DBL (Distance Between Lenses) allowing the use of a smaller eyesize. Using a wide eyewire design or a frame with wide temples can help reduce or disguise thick lens edges (Fig. 2).

Fitting ultra-wide temples usually means that you cannot modify the pantoscopic tilt. In such cases the tilt will be determined by the placement of the patient’s ears. If the tilt is not sufficient, or if one ear is higher than the other, select another frame. If the tilt is excessive, try using an as-worn or individualized lens design to improve the optical performance.

DECENTRATION

Decentration is the movement of the MRPs laterally (usually toward the nose) so both lines-of-sight can pass through them when viewing distant objects. Excessive decentration is a common cause for overly thick lateral edges with minus prescriptions and increased magnification with plus lenses. Excessive decentration can also be the cause for adaptation problems and patient dissatisfaction.

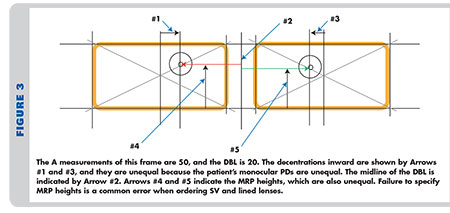

Decentration should be in the range of about 1 to 3 millimeters inward in each lens for most prescriptions. A quick calculation of decentration is easy with just a little practice. This should be done with all prescriptions starting at about 3 diopters of power and higher. For a patient who selects a 50 o 20 frame, the frame PD is 70 (simply add the 50 and the 20), and the monocular frame PD is half that amount or 35 mm (See Fig. 3). In this case the patient’s monocular PDs are unequal, 29 OD and 32 OS (29/32). By subtracting each monocular PD from the frame’s monocular PD, you will find the decentration values (OD 6 mm and OS 3 mm).

BUMPS IN THE ROAD

It is always better to avoid a bump in the road than to suffer the consequences of hitting it head on. OptiCampus.com offers some very useful eyewear tools that can help you avoid unexpected bumps. This link will take you to an easy-to-use calculator function that estimates the edge thickness of minus lenses for various materials: opticampus.com/tools/thickness.php.

The OptiCampus thickness calculator can also be used to estimate the center thickness of plus lenses. This can affect comfort because of increased weight, and it also affects appearance due to the magnifying effect of thick plus lenses. This magnifying effect is more noticeable for longer vertex distances, so a power and thickness that might be acceptable at a 12 mm vertex, may not be acceptable at a 15 or 16 mm vertex.

If the Rx in Fig. 3 were -6.00DS OU, the 5 mm decentration OD will cause a lateral edge thickness of the right lens of about 7.9 mm if the center thicknesses are 2.0 mm with standard plastic. The left lens lateral edge thickness would be about 7.1 mm. If the index were increased to 1.60, the OD lateral edge thickness would be 6.8 mm or 6.3 mm if a 1.5 center thickness was used, and the OS would be 6.1 mm or 5.6 mm if a 1.5 center thickness was used. For a +6.00, the OD center thickness would be about 7.1 mm in standard plastic and 5.6 mm in 1.60. By dropping the eyesize to 48, the center thickness for a +6.00 in 1.60 would drop 11 percent to 5.0 mm and the magnification would drop from 13.1 percent to 11.6 percent.*

With larger lens sizes, the nasal edge thickness of high-powered plus lenses can become a problem if there is a lot of decentration. The OptiCampus thickness calculator is set up to approximate the center thickness of a plus lens that has a 1 mm lateral edge thickness.

ASPHERICITY

Using aspheric curves can also make lenses thinner. This technology allows aberration reduction (primarily marginal astigmatism, power error or a combination of the two). Aspheric curves can be used with higher index materials for even better results in terms of edge thickness for minus lenses and reduced center thickness for plus lenses. Aspheric curves can be molded, but producing them digitally allows you to tailor them more closely to patients’ needs using free-form or individualized designs.

MINUS LENSES

We have all seen minus lenses with excessively thick edges. Minus lenses are always thinnest at the optical center (OC) and thicker away from the center (Fig. 1). It is obvious that if the size of a minus lens is reduced, the edge will not be as thick. If all minus lenses could be fitted in frames so that the optical centers fell near the geometric center (GC) of the eyewire, the lateral (most noticeable) edge of the lens could be minimized (Fig. 2). Ophthalmic lenses that have their optical centers positioned only slightly inward (i.e., decentered) from the geometric centers of the eyewires tend to look and perform better. Lenses should not be positioned with the OC located outward from the GC unless a prism effect is desired. To minimize edge thickness in minus lenses and center thickness in plus lenses, the decentration should be kept to no more than 1, 2 or 3 mm in each eye.

GROOVED AND RIMLESS MOUNTINGS

For lenses that are grooved for a nylon mounting cord, the minimum edge thickness for plus lenses should be at about 2 mm at the point at which the edge is thinnest. Grooved lenses tend to chip if the edge is not sufficiently wide. Using a grooved or rimless mounting for minus lenses is a case of “letting it all hang out,” and is not advisable for higher minus powers. Using grooved lenses in plus powers can add a millimeter or more to the overall lens thickness.

BEVELS

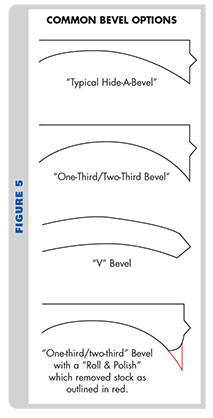

BEVELS With minus powers laboratories usually place the apex of the bevel so that only a little of the edge at most shows in front of the eyewire. With higher minus powers, you may use a hide-a-bevel and specify moving the apex of the bevel toward the back of the lens. This is sometimes called a one-third/two-third bevel, and it moves the apex of the bevel back, allowing more of the edge to show in front of the frame. This reduces the amount of thickness that shows behind the edge of the eyewire (Fig. 3). It takes full advantage of the width of the eyewire and helps disguise the edge thickness of the lens. The edge that appears in front of the eyewire is not unattractive and is usually well-accepted by patients.

If you are fitting polarizing lenses, the apex should not be positioned in a way that allows the embedded polarizing film to be positioned in front of the edge of the frame. If this happens, a white ring will show around the lens. In general, a forward positioning of the bevel’s apex is a good idea for polarizing lenses. If a white ring does show, your lab can tint the edge with a lens edge pen to make the ring less obvious. If the edges are tinted with a lens tinting pen, patients should be cautioned that the tint may disappear if alcohol-based lens cleaners are used.

INDEX

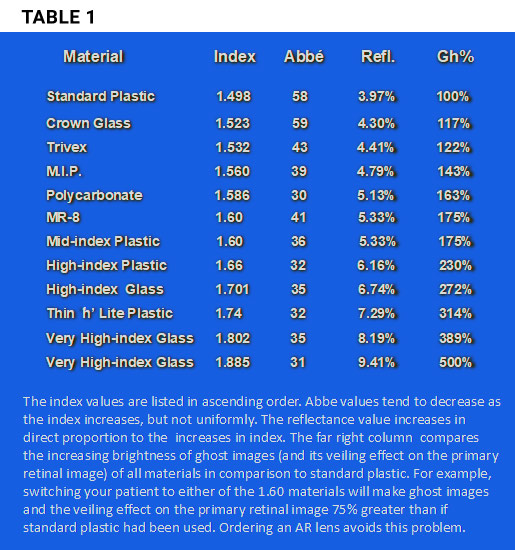

Higher index materials have more light- bending “muscle” so lenses can have flatter curves to achieve the needed power. The flatter curves mean less lens volume, which translates to thinner centers as well as thinner edges. One downside of increasing the index is that this always increases the lens’ reflectance, and there is often a lowering of the Abbe value (Table 1). Both increasing the reflectance and lowering the Abbe value impairs lens performance. The reflectance issue is best dealt with by ordering anti-reflective lenses. With AR, the reflectance remains greater for the lenses with increased index, but today’s top-quality, multi-wavelength AR products reduce reflectance to a very acceptable level.

Abbe value indicates how much blur can be expected due to images of differing color values being displaced unequally. This unequal displacement (i.e., chromatic aberration) creates blur that is seen as a “rainbow” effect at the edge of objects being viewed. In order to know how much chromatic aberration is created at a 20-degree-from-center viewing angle, the power of the lens can be divided by the Abbe value. For example, a 6 diopter lens with an Abbe value of 30 (e.g., 6/30 = 0.20) would have a spread of 0.20∆ at 1 cm from the optical center of the lens, which would be a viewing angle of about 20 degrees for most patients. If the lens had an Abbe value of 58, the image spread would be about 0.10∆. As a general rule, image spread over about 0.20∆ to 25∆ can be patient problematic, especially at longer viewing distances.

KEEPING YOUR DUCKS IN A ROW

KEEPING YOUR DUCKS IN A ROWYour patients assume they will see well with new eyewear, but they also want to look good. Fortunately, technology offers us a lot of ways to achieving those goals. “Bull’s eye” rings of minus lenses are images of the lens edges that are internally reflected. If you use AR lenses (particularly if coupled with a very light tint) these images will be somewhat modulated (although they will by no means be removed), and by making the eyes more visible, and by reducing the brightness of the enlarged reflections from the flat front surface of strong minus lenses, appearance will be enhanced.

Careful frame selection and using AR lenses are both fundamental to achieving the best possible result if you really want to make the lenses look their best. As you know, frame selection has a huge impact on both weight and appearance whenever you must deal with higher-powered prescriptions.

By using special edge treatments and aspheric, atoric, free-form and individualized designs when challenged with such prescriptions, you can make the eyewear more attractive, better performing and more comfortable. Finally, you should consider increasing the index of the lens material you use. As you increase index, optical performance decreases, but these changes are incremental. A good rule is to put increased index at the bottom of your bag of optical tricks, not at the top. If the index must be increased (and sometimes that is a good and necessary choice), that alternative should be your last resort and any increase should be conservative.

YOUR BEST FRIEND

It’s been said that “A boy’s best friend is his mother,” but your dispensary’s best friend is truly your lab. The OptiCampus calculators offer a wealth of guidance for creating really great eyewear, and they should be used regularly. In the final analysis, however, your laboratory can be a huge resource center for your dispensary. They may be able to run calculations, offer suggestions and update you on new and better products (as well as some possibly forgotten options) that can help you become even better known as “the place” to get eyewear that looks good, works well and that is comfortable.■

*When the monocular PDs are unequal, thickness calculations on the OptiCampus computer must be performed twice using each monocular PD doubled. (e.g., for a 29 monocular PD, insert a 58 PD).

Contributing editor Palmer R. Cook, OD, is director of professional education at Diversified Ophthalmics in Cincinnati, Ohio.