By Mark Mattison-Shupnick

We deal digitally daily. Now that’s a mouthful. However, it describes the way we access a good part of our world, and definitely the way we’ll work with the evolving digital labs that produce new digital and free-form prescription lenses. What should opticians and doctors know?

- Understand the lab’s quality and lens verification process, i.e., have they installed methods to verify that the lens’ designs intended are indeed being created? With the shift from factory-produced lenses (front surface progressives, standard toric SV lenses) to optimized and customized designs, your lab has become the manufacturer. Be sure that the lab you choose has a well-defined process to manufacture and verify the lens design you chose.

- Be able to explain the two prescriptions received back from the lab, i.e., prescribed by the doctor and compensated by the lab. The effective power of the lenses when worn has been optimized to deliver the prescribed Rx. That means that the lenses from your lab are different when measured in the lensometer but in the frame at the tilt, wrap and vertex of the frame, provide the prescription that the doctor wrote.

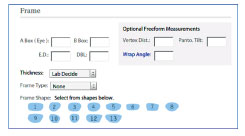

- Know when to use default or position of wear measurements. An optimized lens uses default values; customized SV or progressive lenses use actual position of wear measurements to redesign the lens for the frame chosen and the way it positions the lenses in front of the eye. Without tilt, vertex and wrap values, the lab will automatically use default values. The lab’s online ordering program will have a place to input tilt, vertex and wrap (see example, Optional Free-form Measurements at laramyk.com).

- Think about SV differently. New optimized and customized SV typically does a better job than standard “out-of-the-envelope” SV lenses. Optimized SV designs correct both meridians of a cylinder prescription. Even aspheric lenses only improve one prescription meridian. For SV Rxs, consider ordering optimized SV from your digital lab.

- For higher Rxs (more than +3 and -4) provide pupil center fitting heights so the lab can consider that in the design of the lenses produced (both SV and progressives).

- Electronic ordering may be different lab to lab. For example, if you leave a sign out when inputting sphere power, some labs automatically make it a plus (+), others will call you and processing can be delayed. If there’s no sign for the cylinder power, some labs will default to minus (-) power cylinder, others plus (+), some will put it aside for a callback. Regardless, it all delays the job and may in some cases result in a redo.

- Free-form or digital surfacing (the surfacing process) by itself has limited impact on product performance. It’s the optimization of the design itself and the ability to produce it in the lab that improves visual performance. Choose designs based on your trust in the company’s vision science and the quality of the lab that produces it.

- Lastly, understand the way to communicate and merchandise the results of working with a digital lab. These new technologies improve vision, increase precision, are the latest digital designs and increase the variety of frames a patient might choose. Everyone in the practice should be fluent in digital lens benefits, and that can be used to increase purchase intent, improve capture rate and ensure patient satisfaction.

Essilor’s Tips for Working With

a Digital Surfacing Laboratory

- Understand the lab’s QC process. Are they using a proven quality control process? Most manufacturers provide laboratories with a well-defined process to process their products.

- Understand the product. Digital surfacing by itself has limited impact on product performance. What does the design itself do to improve visual performance?

- Understand the measurements. Many digital products can be customized, but this customization is lost if the practitioner decides to use “default measurements.”

- Understand compensated power. Many digital products have compensated power. Understand how compensation provides more accurate power to the wearer.

- Understand the merchandising. What are the key messages you need to provide your patients with information about digital technology to increase purchase intent?

—Pete Hanlin, ABOM, LDO

Technical Marketing Manager, Essilor of America