By Barry Santini

“My lenses fell out of my eyeglasses, and I didn’t do anything!”

For those of us who camp out on the front line of dispensing, these words bring to mind suspicions of the familiar suspects: a loose screw, a twisted or stretched-out frame, or a warped lens. But there may be another culprit—one whose clandestine handiwork takes place in a very intimate location: the interface between lens bevel and the eyewire groove. Here, any significant mismatch in a lens’ size, proportion, bevel’s contour, position or profile will result in undesirable tension between lens and frame. And much like the hidden seismic tension that underlies an earthquake, unnecessary lens-frame pressure will eventually find a path of release. Lens warpage, micro-cracks, stretched-out frames and temples, warped or rolled eyewires, and lens-surface distortions compromise just a few of the symptoms underlying unwanted tension between lens and frame.

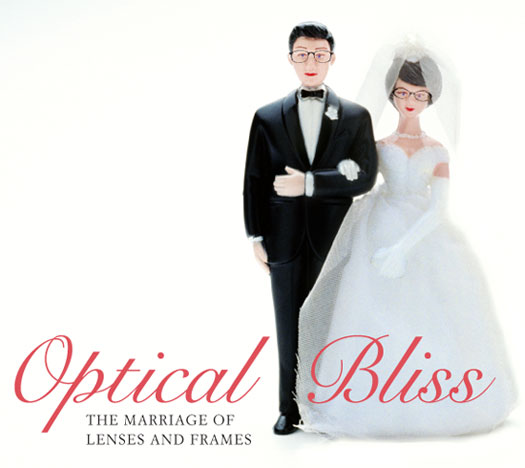

Whether you’re a dispenser or lab technician, there’s much to know and master about creating an ideal marriage between lens and frame. Let’s begin by looking at a “prenup” for the happy union of Rx and frame, whether it is plano or +5.00D.

ENSURING A HAPPY MARRIAGE

When you’re about to “cook” up a new pair of eyeglasses, most ECPs begin with a review of the Rx, dwelling primarily on considerations of lens thickness or progressive-corridor/height. But when the frame selection has been vetted down to a few finalists, how many of us remove the acrylic demo lenses and reconnoiter the eyewire’s inner profile? Proper advance consideration of the factors that influence lens retention can often forecast whether a lens-frame union will avoid an unexpected separation... or worse... a divorce!

THE BASICS OF LENS RETENTION

The essentials of lens retention are easy: If a lens’ total circumferential length matches but is not less than the same of the frame’s inner eyewire, the lens will be ideally held in place. Or will it? Certainly too much lens-frame tension can create problems, such as premature failure of both scratch resistant and anti-reflective coatings.

LENS SIZING

Those ECPs with any extensive experience in the lab know this assumption is far from true. Additional factors, such as both the lens and frame materials’ dimensional stability—defined as summary interaction of both their shrinkage and warpage aspects—will greatly influence lens retention over time.

DIMENSIONAL DIFFERENCES

Despite the arrival of patternless edging and super-precise frame tracers, there continues to be some subtleties in frame tracing that still require the intervention of an experienced eye in order to ensure an ideally proportioned lens. Shapes with very narrow lens “B” dimensions, large A-to-B differences, sharp corners, as well as almost any wrap frame with a panoramic angle of 12 degrees or more will all require the operator to incrementally modify a tracer’s A-to-B relationship for a qualified frame style. Doing so ensures that little undue tension exists in any meridian which could warp or crack either lens or frame. In the near future, we’ll start seeing the introduction of frame tracers that employ a set of proprietary instructions, or algorithms, designed to address these shape anomalies without the need for additional operator intervention.

BEVEL MISMATCH

An often overlooked factor that can significantly influence lens retention is the proper mating of lens bevel to frame. For years, automatic diamond-wheeled edgers have delivered a standard lens bevel profile. While this might have been ideal when most “best form” lenses were either standard plastic or glass, and therefore featured mostly base curves in the range of 4 through 8, the advent of higher index, aspheric and free-form designs means there will be a mismatch between the curve of the frame’s eyewire and the meniscus of the lens’ bevel. A mismatch here can create a mild tension between the lens edge or bevel and the frame’s eyewire groove, and adjacent surrounding structure. This tension is often mistaken as an indication that the lens is properly sized or fitted. Yet, in these situations, any lens or frame shrinkage or warpage can reveal the lack of optimal lens fit.

LENS EDGE PROFILING

One hundred years ago, frames were predominantly made by skilled craftsmen whose goal was to create a lens mount of heritage quality. Today, fashion and novelty dictate frame and sunglass styling, whether intended for prescription or plano. Frames are made in tens of thousands of factories around the world, all at various levels of expertise and quality. Harboring the idea that “all bevels are created equal” is now officially obsolete. The standard “mini” bevel is often not the most optimal, let alone the only choice needed to address the variety of eyewire profiles you’ll encounter.

From rounded to channeled, stepped to lipped and even grooved to hooked, the frame eyewires encountered today pose challenges that are difficult, if not impossible, to meet with a conventional mini bevel.From rounded to channeled, stepped to lipped and even grooved to hooked, the frame eyewires encountered today pose challenges that are difficult, if not impossible, to meet with a conventional mini bevel. But in order to discover what difficulties may lie hidden in your client’s latest online find, you’ll have to start by taking the planos out. Look around at the entire eyewire. Check for areas that pose the greatest prospect for lens-frame interference. Let common sense be your guide when picking the optimum bevel profile to mate the “intended.” Mismatches in profile will also create latent lens-fitting issues. But keep in mind that it is just as important to know when it may be time to let an outside, expert lab complete the job as it is to know which bevel profile or modifications to employ in-house.

A MATCH MADE IN HEAVEN

The optimal matching of lens and frame requires knowledge, experience, proper equipment and the wisdom to know when trying to finish a difficult job in-house is driven primarily by personal ego rather than adherence to the highest standards of our craft. Consider the bottom line for the eyewear consumer: They expect their eyewear to look and see great, and don’t expect their lenses to crack, warp or fall out. Especially today, with the siren of online eyewear beckoning us with the promise that you get more for less, it is important for each and every brick and mortar eyecare practice to strive for the highest standards possible. The curtain has been pulled back: Adequate is no longer enough. Online vendors do adequate well, and for substantially less. With this in mind, every pair of eyewear you dispense should be filled with the promise of excitement and stability as you intone the words: “I now pronounce you lens and frame!”

Barry Santini is a New York State licensed optician based in Seaford, N.Y.