By Mark Mattison-Shupnick, ABOM

This is the second in a two-part feature about investing in an in-office finishing lab. Part 1 ran in the September L&T section.

Creating a Lens Inventory

Lens inventories are an important part of in-office work if fast service is part of the plan. Many of the edger companies have relationships with lens manufacturers so that initial inventories of correct power distributions can be included when the system is installed. Stock houses can also provide next day service for all the varieties of single-vision polycarbonate, Trivex, high-index, AR and/or photochromic lenses. Stock houses are local and quick delivery—in some cases same-day—can be requested by phone or through the Internet by job or a stock order. Lastly, don’t forget the relationship that you now have with the labs. They will continue to supply uncut lenses in progressives and multifocals. Also for a period of time, until your skills are refined, there may be some jobs that will continue to be finished by your lab.

Paying for Equipment

Paying for equipment is like the other capital expenditures you have for your practice. Consider whether leasing or borrowing from the bank is a better solution. The bank will require collateral. Industry financing usually is in the form of leasing programs. Leasing typically requires the least amount of cash outlay. For example, a five-year lease with 10 percent buyout is about $20 per thousand per month. And don’t forget about the tax benefits.

Some company programs support renovation and have borrowable funds available for lab equipment. In today’s economic environment, it is probably best to start with edger manufacturers. They have a variety of methods through leasing vendors that understand the optical business. This can save some time. Be sure to discuss this with your accountant for both the cost and the tax implications.

Other Factors to Consider

Like all new things, adding edging will uncover a variety of additional questions and considerations.

What about drop ball testing? All lenses dispensed in the U.S. must meet the impact standards stated in FDA 21 CFR 801.410. Only a limited number of lenses need to be tested. There are a variety of resources where you may obtain additional information, as well as how to ensure compliance. The Vision Council (www.thevisioncouncil.org) offers a free testing plan you may want to follow as well as certification programs that are also available from testing labs.

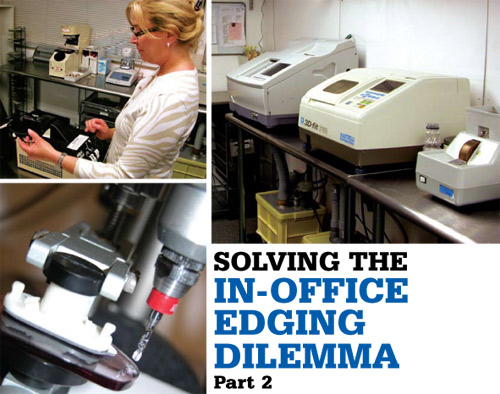

Lab configuration/flow should be discussed with vendors; they can offer terrific advice. The electrical, plumbing and lighting needs are not special but be sure that the environment supports the quality that you expect from the area. More space is better. Of course, ventilation and temperature control are important. If you will be doing a lot of ultra-high-index, 1.67 and 1.74 lenses, they do have an odor. While not a safety concern, good ventilation can ensure that the smell doesn’t invade the dispensary or exam area. Be sure you understand the safety compliance requirements for your city.

Edging may be loud so noise control should be considered—visit a colleague’s office that edges for ideas. Ask the sales representative to help set up a visit to a non-competitive office. Determine how close the lab will be to the dispensary and whether it presents any considerations. Finally, there will be spoilage or errors as well as redo’s. Be sure that selling prices also includes these considerations. The costs spent at the lab already include spoilage and returns in their pricing so you too should charge enough to cover these costs. Allowing staff members to fix any problem unencumbered is appreciated by patients and less stressful on staff.

Getting Started

When speaking with ECPs who are just beginning to get into edging, several key points emerged. Be patient, allow errors and review all mistakes so that the right training is confirmed. Use the sales rep and the vendor’s technical service hotlines every time there’s a question, this way you don’t forget. It took the staff about 90 days to be comfortable. In fact, everyone in the office has had some familiarizing with the equipment. Even reception folks can get a frame traced and saved in the memory of the edger.

On the business side, a lab bill of about $3,000 monthly did support the decision to add edging. Doing work in-office saved about a third of the lab bill and therefore justified the cost of the machine. There was enough single-vision work alone to justify the purchase. “We had a small inventory of scratch-coated plastic lenses but ordered uncuts and stock finished lenses from our lab and a local stock house,” notes one ECP.

As a final comment, he adds, “Why now? It does save money but really increased revenue since it increased our staff confidence and abilities. Discussing options and benefits with patients is easier.”

Upgrading With Drilling

This ECP upgraded from an edger without drilling capability to a new edger with a separate drilling machine and software that automatically integrated the blocker, edger and drill together.

The essential ingredient of a “non-standard” drilling job is the use of a programmable, in-office drill. In this ECP’s opinion, every sale and fitting option counts and the convenience that it affords is the reason to buy new office equipment.

In one week recently, the practice sold three additional pairs of eyewear (rimless), just from putting the shape in a three-piece rimless mounting they carry. These were sales made to people who were either going to use their own frame or just accompanying their spouse for new eyewear. The ASP was very high, even in this market and addressed the patient’s complaint that most of today’s frames were never really right for them. One “custom rimless” a week yields a return twice over what the drilling system costs. Create a personal shape, take the time to make a test lens in the frame to finalize the shape and then finalize it in the correct prescription.

Can you afford to do your own edging? Perhaps the question should be turned around, can you afford not to edge and finish your own work? On a personal note, I still do bench work, and as an optician for the last 40 years, I believe there is a significant advantage in doing one’s own work. It has increased my skills at adjusting and improved my understanding of frame and lens materials. It helps me describe and illustrate the final pair of glasses for the patient so they can best understand benefits and make better choices. In this way, increased patient satisfaction automatically takes care of costs, efficiency and profitability.