I own a small chain of pediatric dispensaries and during the past 22 years, we have filled enough unusual prescriptions that the unusual has become the norm. We use progressives very selectively and do only finish work in my lab. Digital surfacing, the new technology used to produce advanced progressive designs, didn’t affect my business, so, I ignored it. Then little Danielle entered one of my dispensaries.

Danielle is a very bright and cheerful eight-year-old child. She has worn glasses since undergoing cataract surgery as an infant and flat-top bifocal for the past three years. When she recently returned with a new Rx, we were pleased to see that although the add power was being increased, the distance Rx was reduced by a full diopter. Danielle was being prescribed +18.00 with a 2.50 add, O.U. New frames were selected and new facial measurements taken. The child and her mother left our office expecting to pick-up the finished glasses in about 10 days, as they had done several times in the past. However, when we placed the order for Danielle’s new lenses, we discovered that lenticular flat-tops are no longer available. This is when digital surfacing took on far greater significance.

Over the past decade, lenses commonly referred to as “cataract” lenses, steadily have been discontinued. Lenses with oval apertures and apertures of varying sizes and asphericity are gone. Flat-top lenticulars and more recently, round-segment lenticlars have been added to the “endangered species” list. Even labs once boasting large inventories have depleted or limited stock.

While advances in medical technology and technique have made cataract surgery and the use of IOLs (intraocular lenses) commonplace, the results have not been good for some specialty lens manufactures and many ECPs. IOL usage has rendered lens after lens obsolete. Yet, for those infants with congenital cataracts too young for IOLs and others who do not otherwise qualify, this has created a serious problem. While it may not be economical to produce these special lenses, the need remains.

Almost 30 years ago, I had the pleasure of filling a former artist’s prescription. Mrs. Leonard was in her late 60s and had underdone cataract surgery several years prior. In those days, cataract surgery carried far more risk and surgery was not performed until the cataract had fully matured or “ripened.” This woman had not been able to paint in many, many years. She came in wearing lenticular lenses with small bowls (apertures) and 18mm round segments. I used a much larger oval aperture lens—cutting-edge technology for the time—with a FT-25 segment. When I delivered the glasses, the woman cried. . . and almost immediately, she started to paint again. The lens I once used so successfully on Mrs. Leonard was discontinued many years ago and not because of product advances. Danielle, Mrs. Leonard and many others are in need of lenses no longer profitable to manufacture.

As I searched for a lens for Danielle, it occurred to me that digital surfacing might provide a solution to our problem. Although the technology has largely been used to produce PALs, it is capable of producing many other lens styles or designs. Using digital technology, labs can turn a semi-finished, single-vision lens blank into a finished lens matching the lens criteria ordered. Single-vision, bifocal or progressive, atoric or aspheric, bi-concave or bi-convex, virtually any lens can be created. Using digital technology, not only do we have alternatives, we can also create even better lenses.

ASPHERIC LENSES

Aspheric lenses are not new to the optical industry. Aspherics have been used to improve the peripheral optics in low-vision magnifiers and since the 1970s to produce progressive lenses. Generally, aspheric lenses improve optical performance and the flatter curves enhance the appearance, especially of plus lenses. However, the higher the plus power, the less likely we are to find the lens available—until digital surfacing. Now, patients most in need of optimal visual enhancement have access to the improved optics of aspheric lenses, in both bifocal and single-vision lenses.

ATORIC LENSES

Several years ago, we were introduced to single- vision lenses, with atoric curves on the inside of the blanks. These lenses were only available in polycarbonate and high-index plastic and only in finished form, as the U.S. did not have the digital technology required to surface the lenses. However, using digital surfacing technology, we can now produce thinner, more accurate lenses, with expanded visual fields, in virtually any material. Digitally surfaced atoric lenses are limited neither to finished blanks nor single-vision prescriptions. This means we can use lens materials with higher Abbe values and still produce thinner, more attractive lenses by adding atoric surfaces— something myopes appreciate.

PROPRIETARY/UNIQUE LENSES

ECPs like proprietary products. We like to offer something unique, something our patients or customers can reasonably get only from us. Digital surfacing has been touted as the most precise method of managing vision corrections. While the consumer’s appreciation of the increased accuracy may be negligible, digital technology offers something far more tangible.

Digitally surfaced lenses offer personalized lens design without financial investment by the ECP and measurements are obtained using conventional techniques and equipment. The uniqueness of the lenses is mainly dependant on the skill of the practitioner ordering the lenses and the lab equipment and software from whom the practitioner obtains the lenses.

AND THE LAB HAS KNOW-HOW

The customer must return to the practitioner and the practitioner must reorder lenses from the same lab, definitely a win-win for the ECP and the lab. In addition, since the end- product is relatively exclusive, price shopping is all but impossible for either the consumer or the ECP. The ECP has increased product availability at a comparable cost, product with enhanced optics and products that are relatively exclusive.

WILL DIGITAL’S PROMISE BE FULFILLED? What I found when looking for a lens for Danielle, was that although digital surfacing holds enormous promise for producing high powers and other specialized lenses, few of the independent labs have the experience, equipment or money for digital surfacing. Most of the larger, multi-location labs using digital technology do so to produce the more lucrative PALs and do not have the specialized design files or the equipment needed to turn out unusually high powers and other atypical prescriptions.

As operations manager for Walman Optical, Chris Bowers has invested time and considerable funds implementing digital surfacing progressive lenses. While Walman could expand their digital capabilities to include lenticulars and other “hard-to-find” products, he understandably questions the return-on-investment. As Bowers explains, “Walman processes thousands of lenses daily, but has almost no demand for out-of-range products. We hope that as digital surfacing becomes more commonplace, associated ‘click’ fees [for the use of patented design and generator integration software] will be reduced to make expanded usage more feasible.”

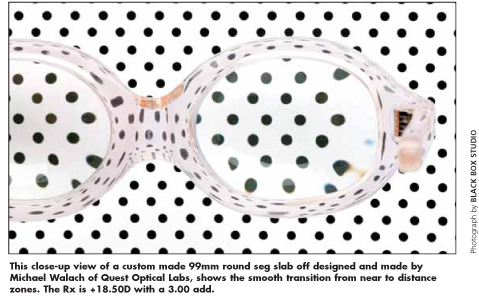

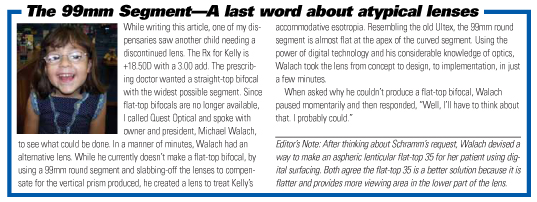

Michael Walach, president of Quest Optical Specialty Lab in Largo, Fla., specializes in producing lenses other labs find cost prohibitive. Walach sees click fees simply a cost of doing business and considers the fees reasonable and quite manageable. He also foresees generic programs on the horizon where the fabricating lab will purchase the software outright, thus avoiding any usage or click fees. This would certainly open the door to other labs expanding their digital capabilities.

Today, if Mrs. Leonard were still around, I would introduce her to a digitally surfaced, aspheric lens with improved optics and a wider reading segment. I’d give her one lens specifically designed for her right eye and another specifically designed for her left. For Danielle? With the technology we now have available, I’ll use a digitally surfaced aspheric bifocal lens. Not only will the optics be improved, the lenses will look better.

When asked about the future of digital surfacing, Michael Walach replies, “This is it. Digital surfacing is the future.” I couldn’t agree more. LT

Katheryn Dabbs Schramm, FNAO, ABO, is president and CEO of A Child’s View, Inc., a four-location optical dispensary in Southern California specializing in pediatrics. She is a recognized authority on children’s eyewear and author of the book “Dispensing Pediatric Eyewear.” She is an ambassador for the National Academy of Opticianry and writes for ophthalmic trade publications.