In 1669 Danish scientist Erasmus Bartolin discovered that calcite crystals could polarize light by a phenomenon called double refraction, now commonly called birefringence. In the mid-1960s there was speculation that Bartolin was predated by more than half a millennium by some sailors, Vikings, who used the crystals to locate the sun through cloudy arctic skies for navigation.

Regardless of who discovered it, used it first, or explained it,

birefringence has important applications for ophthalmic dispensers. The

basis of these applications lies in the fact the stress on some

transparent materials causes birefringence or a partial depolarization

of polarized light passing through the lens. Unfortunately only a few

dispensers today are making use of this practical and easily mastered

tool.

Regardless of who discovered it, used it first, or explained it,

birefringence has important applications for ophthalmic dispensers. The

basis of these applications lies in the fact the stress on some

transparent materials causes birefringence or a partial depolarization

of polarized light passing through the lens. Unfortunately only a few

dispensers today are making use of this practical and easily mastered

tool.

Remember air-tempered glass lenses?

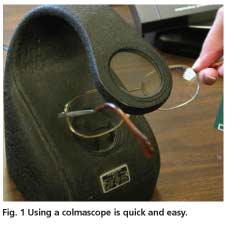

The uneven pressure within the lenses gave rise to a birefringence that can be easily detected with a colmascope or polariscope (Fig. 1.) As air tempering became obsolete and plastic replaced glass, colmascopes were eliminated from the tools of many dispensers.

BUT WHAT ABOUT TODAY?

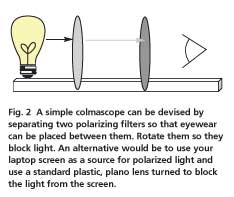

Lens stress can still provide important clues to help dispensers avoid problems with new eyewear and you can easily use birefringence as a tool for detection, analysis, and to guide you in correcting problems and potential problems. Also, if you don’t have a colmascope, it is easy enough to devise one (Fig. 2).

MECHANICAL PROBLEMS

MECHANICAL PROBLEMS

Visualized stress can help predict lens chipping and fracturing. A quick colmascope enables you to identify lens areas that will be prone to chipping and fracturing. A lens “too tight” in the frame can chip when even a small amount of twist or bend is applied. The area that is chip-prone will show up as a light area in a colmascope and the brighter and more concentrated the area of light, the more chip-prone that area will be. Usually, simply loosening the eyewire screw a half-turn or so will relieve the stress and prevent chipping during dispensing. Chipping most often occurs if the temples are not splayed enough for the patient’s head at the outset. Once the frame is completely aligned, the eyewear screw can be safely tightened—an important step that should not be overlooked.

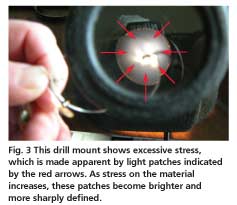

Drill-mounts are most likely to chip around these holes when the birefringence patterns are sharply defined (Fig. 3). A little practice will tell you when to be especially careful as you adjust the drill-mounted eyewear.

VISION PROBLEMS

Lenses too tightly clamped in an eyewire may develop warped areas that can make adaptation difficult. Often this clamping causes stress that can be easily seen on a colmascope. If you suspect a patient with adaptation problems may have a warpage problem, the lens must be removed from the frame, sized down slightly, heated gently in warm (AR lenses) or hot water and reinserted. You should do a colmascope check for stress before going through all this. Warped areas, once identified, are often best seen by reflected rather than transmitted light. Lenses with very thin edges or very thin centers are especially prone to warpage.

POLARIZING LENSES

Polarizing

lenses represent one of the absolute best of today’s ophthalmic

technologies. They selectively eliminate useless reflected glare and

give an easily perceptible improvement in sunwear performance.

Polarizing

lenses represent one of the absolute best of today’s ophthalmic

technologies. They selectively eliminate useless reflected glare and

give an easily perceptible improvement in sunwear performance.

If polarizing sun lenses arestressed by being too tightly mounted in the frame, they will show “patchy” transmission of polarized light because of birefringence. A colmascope is not needed to view this decreased performance. Simply placing the lenses in front of a polarizing light source and rotating them for maximum darkness will quickly reveal any patchy lightened areas. It is important to recognize that small, peripheral lightenedpatches will be of no practical significance, but a large or central lightened area can seriously affect lens performance.

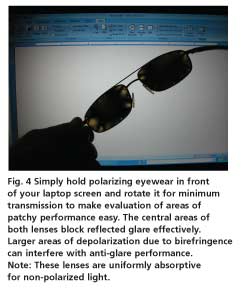

If you have a polarizing demonstrator, you may be able to us it to detect areas of birefringence by just holding the polarizing sun eyewear in front of the unit. An even easier method is to hold a plano polarizing plastic (not poly) blank in front of the lens you are testing, rotate the blank until it appears to be dark when viewing through the sun lens you are testing. Any light or patchy areas will be apparent (Fig. 4). This test should be done after the patient’s new lenses have been mounted in the frame.

ABOUT POLYCARBONATE

Most polycarbonate lenses have internal stress that will give a colorful birefringence pattern in the colmascope. This internal stress does not affect vision nor does it prevent locating chip prone areas.

Birefringence is an easy-to-use dispensing tool that can help you avoid chipping. It can warn you of warpage and it can assure that your patient’s get top-notch performance from their polarizing sunglasses. The Vikings used it, Erasmus Bartolin challenged the wave theory of light with it and today’s dispensers can and should use birefringence to make their jobs a little easier

and their patients a little happier.

Palmer R. Cook, OD, is director of professional education for Diversified Ophthalmics in Cincinnati.