| New Products |

|

|

| |

|

Operating Strategies |

|

|

Bob Niemiec |

Automation: Getting to

Where You Want to Be,

Part 1

As the world of optical manufacturing moves increasingly toward digital surfacing and as the pressure to consistently produce high quality products at lower cost continues, automation stands as a means to these ends. The ability to automatically convey work from station to station coupled with pick and place insertion of lenses into the various machine tools can provide an enormous benefit in the key areas of service, cost and quality.

For many labs, though, this can be a daunting proposition when considering not only the capital investment required but also the investment required in terms of people, skills, training. Additionally, given the current state and history of your lab, change may be required from a culture and operating standpoint as well. The return on an investment in automation, when done correctly, can range from positive to very positive in all but a very limited number of cases. Still, there may be a reluctance to jump in, especially for those whose experience with automation may be little to non-existent. To those, I would just quote an old proverb, “the best time to plant a tree was 20 years ago, the second best time to plant a tree is today.”

The first concern when contemplating automation is assessing the benefits as well as potential challenges. This is largely a function of your current state of operation as well as the degree to which you are looking to automate. An important part of assessing the current state is knowing your current costs and cost drivers in some level of detail.

Understanding where you are currently in the areas of cost, quality and cycle time is the starting point for justifying the investment as well as, upon implementation, understanding the realization of benefits. Additionally, automation is not an all or nothing proposition; depending on your current state and any prior history in attempting automation, an incremental approach may be best. Among the potential benefits of automating are reducing work in process, reducing and/or eliminating direct and indirect labor, faster cycle times, more consistent job flow and higher, more consistent first time quality.

—Bob Niemiec is president of Optinova Solutions, LLC, a consulting firm specializing in operations improvement, new technology assessment and mergers and acquisitions, primarily in the optical industry. An optical industry veteran, he has held senior level positions in manufacturing and distribution with large optical retailers and manufacturers. He can be reached at

[email protected]. |

| |

|

Tech Talk |

|

Tinting High-Index Plastic

As the number of high-index lens materials on the market continues to grow, it's important for lab technicians to check with the lens manufacturers about the tintability of each new material. Here are some general guidelines for tinting high-index plastics that will also be helpful.

|

|

Photo courtesy of Optisource. |

-

The challenge in coating high-index lenses is the multicoating. Coated lenses require different tinting times. When tinting a coated lens, remember that in many cases it is the coating that is being tinted, not the lens material. Don't mix coated and uncoated lenses—or even different coatings—in a lens pair, as each lens will likely tint varying hues and densities and require time-consuming corrections.

-

Don't immerse high-index lenses in dye or neutralizer for more than five minutes at a time to avoid coating damage.

-

Don't leave high-index lenses unattended. Check for color and overall condition every one to two minutes.

-

Typically, gray and brown standard plastic dyes produce bluish-cast in high-index lenses.

-

If you are processing more than five percent of your work in high-index, dispensers recommend devoting some dye pots to high-index work and obtaining specially formulated dyes for the best results.

-

For the best results for a dark high-index tint, use backside-only coated lenses for better absorption. |

| |

|

HR Corner |

|

Planning Now for Summer Vacations

It certainly does not seem possible, but summer is upon us. So before the summer actually melts away, you should take some time to ensure that your practice staff plan and take needed time off. Here are a few reasons:

-

If you wait, inevitably the practice will become too busy and it will become difficult to schedule time off on short notice;

-

Finding capable temporary staff to 'fill in' is not as easy as it may seem, especially when it comes to your practice and your patients;

-

While some employees may not want to take time off, it is important from a productivity standpoint—for them and for your practice, to do so.

So how can you ensure that your staff takes necessary and well earned time off?

-

Remind your employees of the amount of paid time off they have accrued, and that their PTO is a benefit that they have earned and should take. Ask when they would like to schedule their summer vacation or short break and help them think ahead.

-

So that you can plan for the employee's absence, ask your team for at least a month of advance notice to ensure there are no dual requests that might leave you short staffed and so you can have a clear calendar of when employees will be away from the office.

-

While some employees will be on vacation, do remind them that if an employee checks e-mail and voice-mail, there may be an issue as to whether a vacation day has actually been taken or pay is required.

Summer should be a good time for your team to take a break from the busy schedules that are so often the norm in the eyecare practice world. But remember, summer isn't the only time for vacations and these time off tips can be applied throughout the year, especially once the holiday season rolls around.

—Hedley Lawson brings over 25 years of optical industry experience to Jobson Medical LLC. For over 10 years, he has been a contributing editor to VM, most recently as writer of the monthly column “Business Essentials.” He is the Contributing Editor of VM's E-Newsletter

Business Essentials. |

|

|

Assessing Financial Performance,

Part 3

Quality financial statements are an absolute necessity for lab owners and management to make sound and timely decisions relating to cash flow, sales and expenses and budgeting. Those decisions are only as good as the information used to make them. In previous articles, we've stressed the importance of accrual basis financial statements. Although many labs do keep their financial reporting on an accrual basis, they often do not include certain liabilities or potential offsets to current assets, and in-turn overstate the performance of the lab. This month, we will focus on offsets to assets and follow up next month with overstated liabilities.

Most labs do not incorporate allowances for discounts or doubtful accounts. These two items are often overlooked because of complication or extra work involved in their computation or by a lack of understanding of the accounting staff. Accounts receivable should be stated net of these items on the balance sheet.

Discounts

Everyone in the industry is acutely aware of discounting. Many accounts don't ask about the price first; they ask about their percentage discount. If you are not sure if receivables are stated net of the discount allowance, ask yourself, “Does the company intend to collect the entire amount of receivables on the aging report?” If not, a discount allowance should be included to offset the receivables. The best way to determine the amount of the allowance is to take the percentage of discounts granted in the current month and determine their percentage of the previous month’s gross sales. Then apply that percentage to the current month’s gross sales. The product would be the allowance for discounts at the end of the accounting period. Be careful though. If your lab is in the practice of granting discounts on accounts even when they are past due, a more conservative analysis may be needed for the sake of accuracy.

Allowance of Doubtful Accounts

Unfortunately, not everyone pays their bills, as many lab owners know all too well. While we can't always determine which accounts will likely be uncollectible, we can estimate the potential loss based on historical experience, or through a detailed account by account analysis. The latter takes much longer, but is more accurate. The former is fairly accurate and can be determined quickly each month. In order to estimate the latter, look to the historical bad debt that has been written off, how old each bad debt was on an aged basis, then compute the percentage of all bad debts for each time period (i.e. +30 days, +60 days, +90 days), and then apply those percentages to the current aged receivables to determine the allowance for bad debts. Be careful to do this only after an allowance for discounts has been computed or you may overestimate the allowance for bad debts.

Read “Assessing Financial Performance, Part 2.”

Read “Assessing Financial Performance, Part 1.”

—Jason A. Meyer is senior vice president, HPC Puckett & Company. Based in San Diego, Calif.,

HPC Puckett & Company specializes in mergers and acquisitions of wholesale optical laboratories. You can send comments or questions about this article or any other Dollars & Sense articles to Jason Meyer at

[email protected]. —Jason A. Meyer is senior vice president, HPC Puckett & Company. Based in San Diego, Calif.,

HPC Puckett & Company specializes in mergers and acquisitions of wholesale optical laboratories. You can send comments or questions about this article or any other Dollars & Sense articles to Jason Meyer at

[email protected].

|

|

| |

|

|

|

VSP Expands Lab Network With Acquisition of Ultra Lens

|

|

Danny Singer

of Ultra Lens |

VSP is expanding its growing network of prescription optical laboratories with the purchase of Ultra Lens optical lab in Fort Lauderdale, Fla.

The lab had been privately owned by the Singer family. The purchase price was not disclosed.

Ultra Lens is a full-service wholesale lab founded in 1975 by Bud Singer and currently operated by his son-in-law, Danny Singer. The current management will stay on to run the lab, according to VSP. The lab, which has 35 employees, produces about 450 jobs per day and services customers throughout Florida as well as in other states. It operates an in-house anti-reflective coating facility, and is an authorized distributor of Hoya, Shamir, Varilux and Zeiss products.

“Adding Ultra Lens to our VSP lab network continues our commitment to providing the highest quality products and best service to our clients, doctors and members,” said Don Oakley, VSP vice president of ophthalmic supply chain and services. “This acquisition provides VSP doctors with an even broader variety of advanced optical lab technologies and services from which to choose, ultimately benefiting the 700,000 VSP members in Florida and the 55 million members nationwide.”

Danny Singer said that being owned by VSP “will enhance our ability to even be better than we were.” As an example, he noted that Ultra Lens would now be able to service VSP doctors. “We were not doing VSP jobs before, but it's something we've always wanted to be able to provide,” he said.

Ultra Lens is now VSP's fourth wholly-owned lab, along with Legends 4.0 in Dallas, Texas, and the VSP Labs in Columbus, Ohio and Sacramento, Calif. The company shares ownership in Perfect Optics in Vista, Calif. and Tri-City Optical in Clearwater, Fla. through joint venture agreements with Carl Zeiss Vision and management. |

| |

|

|

|

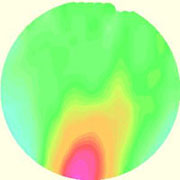

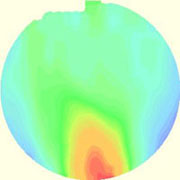

Producing a PAL With Extreme Cylinder

Ice-Tech Advanced Lens Technologies, in Atlantic Beach, Fla. specializes in difficult Rx work. President Allen Weatherby described a typically challenging job his facility recently produced.

“We had a customer who called with this uncut job that had a pretty extreme cylinder,” said Weatherby. “The customer wanted to know if we could we do it in a progressive. We produced it in Trivex Transitions.”

The Rx was as follows:

Sph -3.00 Cyl -5.75 Axis 010 ADD 2.00 Maximum edge thickness of this lens was 4.8mm with a minimum edge thickness of 2.4mm. CT thickness is 1.0mm (Trivex).

Sph -2.50 Cyl -6.00 Axis 168 ADD 2.00 Maximum edge thickness of this lens was 4.6mm with a minimum edge thickness of 2.3mm. CT thickness is 1.0mm (Trivex).

|

|

|

Left Sphere |

Right Sphere |

|

|

|

Left Cylinder |

Right Cylinder |

As the power changes, the colors change. Note how stable the power is across the surface of both the sphere and cylinder maps of this job.

“We don't use standard lab management software,” noted Weatherby. “We've developed a customized 'Ice-Tech Lens System,' which is a combination of software and hardware. Our customized software drives everything.”

“Many of the jobs we do that get into outer bounds territory, we don't know for sure if we can make it until we attempt to calculate each job,” he remarked. “Each lens is individually designed based on the prescription and the frame trace data or A, B, ED, PD and DBL,” he said. “In most cases we base curve match the front curve to fit the frame. This assures a very good cosmetic solution.”

“We also produce really big wraparound lenses using our wrap compensation and individualized lens calculation,” Weatherby added. |

|

| |

|

|

Kayla Berger of Meridian Optical

Kayla Berger started in the lab business in 1988 at Sierra Optical in San Diego, Calif. She worked in the accounting department as an accounts receivable clerk. Kayla Berger started in the lab business in 1988 at Sierra Optical in San Diego, Calif. She worked in the accounting department as an accounts receivable clerk.

In June 1996, Berger joined another local lab, Custom Craft Optical, which was then owned by a father and son team. The lab was later acquired by Essilor and is now known as

Meridian Optical.

Meridian spends a considerable amount of time and effort training their employees to deliver superior service. As the customer care representative and inventory specialist, Berger is primarily responsible for answering the phones.

“I make sure my customers are taken care of to the best of my ability,” she said. “I answer technical questions, expedite orders when needed, pull inventory, order inventory and stock the shelves.”

Although Meridian is part of Essilor's extensive lab network, it maintains a small lab feel, employing about 10 two 12 people. “It's a great place to work,” Berger told Lab Advisor. “Overall, we work as a team and strive to be the best we can be.”

Each day, Berger arrives at work with phones already ringing. In addition to customer care, she begins her day by processing orders and pulling inventory.

“I count inventory on a daily basis to keep it under control, and do all lens ordering around noon each day,” noted Berger. A typical day also includes troubleshooting jobs that have failed in lens selection and making phone calls to customers to make changes to orders.

“What I love most about my job are the friendships I've made with my co-workers and customers over the years. The optical knowledge I have gained is a close second,” said Berger, who enjoys attending Essilor seminars and meeting customers in person whom she speaks with daily on the phone. Berger was recently recognized at her laboratory for providing exceptional service by one of her customers, Kristin Giles at Coronado Eye Care, in Coronado, Calif.

“I'm so happy where I am right now,” she said. “I love working in customer service and I enjoy taking charge of the lens inventory.”—Samantha Toth |

|

| |

|

|

Trash to Treasure

Turn your used finishing pads into treasure when you enter the Trash to Treasure Finishing Pad Art Contest. Create a work of art—a two dimensional “painting” or a three dimensional “sculpture”—from your used blocking pads and you could win up to $500.

DAC Vision, the originators of the finish pad art contest, is teaming up with LabTalk magazine and Saint-Gobain Performance Plastics to expand the art competition for 2008. Prizes include:

-

1st Place — $500 American Express Card

-

2nd Place — $250 American Express Card

-

3rd Place — $125 American Express Card

-

Honorable Mention — One roll of SecurEdge Finishing Pads

(Winner's choice of shape.)

To enter a piece of art, package up the creation and mail to: Jobson Medical Information, Attention: Finishing Pad Art, 100 Avenue of the Americas, 9th Floor, New York, New York, 10013, by the Sept. 15, 2008 deadline.

All artwork will be photographed in the Jobson studio for judging. Photos of the winning entries will also be published in the November/December issue of LabTalk and in the November issue of Lab Advisor.

|

| |

|

|

Satisloh 'SLUGfest' Offers Training, New Technology—

Satisloh gathered its customers and vendor partners in Milwaukee for a three-day meeting last month, just days after announcing that it will be acquired by Essilor. The three-day event, billed as SLUGfest (Satisloh Users Group), attracted about 150 attendees, including managers and technical personnel from various wholesale and retail optical laboratories.

|

|

Larry Clarke, president of Satisloh North America greets SLUGfest attendees. |

|

|

Putting the new LaserOp LensMark II engraver through its paces are, left to right, Dr. Pinchas Agmon of LaserOp, Mike Rybacki of Seiko, Paul Faibish of Plastics Plus and Greg Eifert of Satisloh. |

|

|

Beat Siegrist, CEO of Schweiter Technologies and Satisloh, answering questions from attendees at a dinner reception. |

This was Satisloh's second SLUGfest, the first having taken place two years ago. Like the previous SLUGfest, the meeting served as a platform for Satisloh to preview its latest lens processing technology and provide customers with hands-on technical training in surfacing, finishing and coating ophthalmic lenses. It also provided an opportunity for Satisloh CEO Beat Siegrist to speak directly with customers about how they will be affected by the pending acquisition and respond to their concerns.

Larry Clarke, president of Satisloh North America, kicked off SLUGfest by presenting a technology “roadmap” and strategies to help labs compete for the next several years. Attendees then traveled by bus to Satisloh headquarters in nearby Germantown for a full day of seminars covering various aspects of ophthalmic lens processing. Satisloh previewed several new products, including a compact, modular generator capable of direct surfacing as well as anti-reflective, hardcoating and filtration equipment.

During the following two days, Satisloh presented technical workshops, including sessions on tips and tricks for cut to polish process management, lab automation and human resource management, personnel training and using software for preventive maintenance. A number of lens suppliers offered an update on digital surfacing technology, including Michael Ness of Vision-Ease Lens, K.C. Haffey of Essilor, Álvaro Arias of Indo, Michael Rybacki of Seiko, David Jochims of Carl Zeiss Vision, Jerry Thornhill of Shamir Insight and Dave Delle Donne of Optical Distribution Corp., Rodenstock’s U.S. distributor.

“It's a very interesting meeting. There’s a lot of good new equipment to see here,” remarked Chris Bowers of Walman Optical. “I'm really impressed with the disposable block and the Orbit generator,” he said, referring to two new products Satiloh will be introducing later this year. “The most impressive thing is that a major vendor shares its philosophy with us,” Bowers added.

Twin Cities Moves Cedar Rapids Production to Minneapolis—Due to the recent flooding in the Midwest,

Twin Cities Optical Cedar Rapids has moved production of all lab jobs to the TCO Minneapolis facility.

|

|

Flood waters surrounding the back of Twin Cities Optical in Cedar Rapids, Iowa. |

|

|

Susie Thede, left, and Makala Diercks from ELOA's Twin Cities Cedars Rapids lab organizing and entering jobs at the company’s Minneapolis lab. |

“Fortunately, both labs are part of the largest network of optical laboratories, Essilor Laboratories of America (ELOA). This affiliation allows us to strengthen your optical laboratory needs with a seamless transition to other Essilor laboratories,” according to Bob Degregorio regional vice president, north central region ELOA in a letter to TCO Cedar Rapids customers.

Currently, TCO Cedar Rapids customer service group is working out of a conference room in a hotel near the Minneapolis lab, and production has not suffered as a result of this loss, according to the letter. Also during this time, approximately 50 percent of the TCO Cedar Rapids staff has relocated to assist with the increased workload assumed by TCO Minneapolis.

Degregorio told customers, “Our sales and customer service departments will be contacting you in the coming days to address any questions concerning your account. In the meantime, please continue to place your orders through TCO Cedar Rapids as we transition your account.”

Katz & Klein Launches Polarized Packages—The management of

Katz & Klein believes polarized lenses offer a great value to ECPs and their patients. That's why the Sacramento-based wholesale lab recently launched two polarized lens package programs.

One program is in partnership with sunglass supplier

Marco.

|

|

The Model 5a is one of the Marco polarized sunglasses distributed by Katz & Klein. |

“The ECP can sell the Marco product as plano sunwear, but more importantly we have packaged the frames for prescription,” detailed Mike Francesconi of Katz & Klein. “Single-vision, bifocal and progressive are available. All the packages come with or without backside AR. The idea is to offer the ECP turnkey options on presenting polarized sunwear. We also offer a polarized package for lenses only, again for single-vision, bifocals and progressives because we know that the Marco collection fills just one part of the total ECP's frame needs.”

The lab also promotes its own polarizes packages. One package is called Polarized Italian Sunglass Extravaganza. Another is called Your Eyes.

“This is the program where we give the ECP package pricing on lenses to incorporate with their existing sunglass inventory. The brands we are offering are Nu-Polar by Younger Optics in both polycarbonate and CR-39 and Drivewear in CR-39,” said Francesconi, referring to the popular PPG monomer used to make plastic lenses.

Second Major Expansion Project in Two Years for FEA Industries—

FEA Industries, an independent lab located in Morton, Pa., recently aquired a second building to expand its manufacturing of prescription lenses. The second facility, located 500 feet from the current laboratory, will increase the work space to 31,000 square feet.

“We purchased the second building as part of our planned expansion,” said William Heffner, chief executive officer. “We were approching maximum capacity for space and machinery. The additional building will permit expansion of conventional lens surfacing. Additionally, new robotic production lines will be installed to process the latest in digitally surfaced lenses like the Kodak Unique progressive [from Signet Armorlite],” added Heffner.

Surfacing, finishing, and product distribution will be moved to the new facility. The AR and mirror coating laboratory will remain in the present location along with customer service.

Heffner noted that FEA recently hit a production milestone by processing more than 1,000 prescriptions with Kodak CleAR Coating in a one-month period, the highest number of prescriptions processed through any SA KODAK CleAR Lab in a month, according to Signet Armorlite.

“This move will also permit us to add a third AR coating machine and space for additional machines as the premium AR market grows,” said Heffner. | |

|

|

|

Clip&Read

Manufacturer: Eschenbach

Description: Small reading glasses that attach to electronic devices for easy access

Target Customer: Presbyopic patients that have difficulty reading their cell phone or digital camera screen or have a problem finding their reading glasses when they need them.

Features: Clip&Read is a miniature pair of reading glasses that can attach to any portable device (cell phone, digital camera, laptop) using either a lanyard or velcro fastenings, so they are available when and where they are needed. Available in two powers (1.5D and 2.5D) and two colors (gray and red), with short flexible temples that sit in place on the temple of the patient without any pressure points. The glasses weigh only 3.3 grams and come with a case. A rotating 12-piece display is also available.

(800) 487-5389

www.eschenbach.com |

| |

|

Varilux Physio 360º Expansion

Manufacturer: Essilor of America

Description: Expansion of the Varilux Physio 360º line to include cylinder powers up to -6.00D in all materials

Target Customer: Patients with complex prescriptions

Features: The expansion of the Varilux Physio 360º line allows ECPs to provide the sharpest vision possible to customers with high cylinder prescriptions. In addition, Varilux Physio and Varilux Physio 360 1.50 plastic lenses are now available with a sphere power range of +6.00D to -10.00D in Clear, Transitions VI and Polarized.

(800) ESSILOR

www.essilorusa.com |

| |

|

Optera Software

Manufacturer: Optifacts

Description: Excel-compatable presentation software

Target Customer: Optical labs

Features/Functions: Optera software allows data from Optifacts software to be imported into Excel to create custom reports, graphs, tables and charts. Users can view, search, and report on the data in any way. Several pre-designed templates are available, but advanced Excel users can create reports from scratch.

(800) 678-4322

www.optifacts.com |

| |

|

|

2008 Tool & Supply Catalog

Manufacturer: Vigor Optical

Description: 2008 Tool & Supply Catalog

Target Customer: Dispensers and lab technicians

Features: New items of interest would be the new ergo handle adjusting pliers, the expanded bulk screw offering for high volume users, the Vigor pupilometer, large lab size job trays, and an economy lens clock.

(800) 847-4188

www.vigoroptical.com |

| |

|

Aqua-Sonic Lab Model Ultrasonic (#4050)

Manufacturer: Western Optical Supply (WOS)

Description: Ultrasonic cleaning machine designed for high-volume labs

Features: The Aqua-Sonic Lab Model Ultrasonic by Western Optical Supply was designed for extended periods of operation in high volume environments like busy offices and laboratories. Featuring five preprogrammed timed cycles—90, 180, 280, 380 and 480 seconds—and a large 40 ounce capacity, the ultrasonic machine uses an ultrasonic wave frequency of 42,000Hz at 60 watts power. The machine comes with a free quart of Biodegradable Ultrasonic Cleaning Solution.

Size: inches high by 6-1/4 inches wide by 9 inches deep

Price: $140

(800) 423-3294

www.westernoptical.com |

| | | | |

| In This Edition...

|

| |

|

•

Subscribe to Lab Advisor

The monthly update for Optical Laboratory Owners and Managers

•

Forward this issue of Lab Advisor to a friend or colleague

•

Print this issue of Lab Advisor

•

Stay on top of optical industry news!

Subscribe to our other

e-newsletters:

•

VMail Extra

•

Business Essentials

If you have lab news or want to share information about technical topics, please

contact us.

Or

contact

Andrew Karp,

Editor-in-Chief

Visit

LabTalkonline.com for additional articles of interest about labs. |

| |

| |

|

| |

LabTalk Spotlight

July 2008

While everyone in the lab business understands the importance of the generator and the edger, what about all the auxiliary products that are needed in order for a lens to actually end up in a frame?

Often forgotten and misunderstood, there are other pieces of equipment that play a key role in both lens processing success and lab operation improvements.

In order to identify these “unsung” products in the optical laboratory, Linda Little asked laboratory owners and managers what pieces of equipment they liked in their labs aside from the generator or edger. Check out what they had to say in the July/August issue of LabTalk article, “Labs Identify 'Unsung' Laboratory Equipment.”

“Probably owned by every lab, and maybe taken for granted, the rimless drill was the leader among the unsung equipment favorites. As Dave Lea, of Lea Optical, Clearwater, Fla., put it, 'the rimless drill machine revolutionized that part of the business.' The first Optidrill, distributed by

Salem Vision, was felt to do a great job with relative ease. With the availability of this product, rimless lens sales grew tremendously. The Optidrill brought the technology laboratories needed to meet the market demand. The frame shapes were now repeatable, the quality consistent, the cost of production was lowered, and a mix of holes and notches could be created. Breakage at this step was very expensive for a laboratory and the Optidrill reduced this risk.“

To read the entire article, “Labs Identify 'Unsung' Laboratory Equipment,” log on to

http://www.labtalkonline.com/. Here you will find the article listed under the Features section.

|

|

Buying Group & Lab Association News

OLA Announces 2008 Awards of Excellence Nominees—The Optical Laboratories Association (OLA) released its list of nominees for the 2008 Awards of Excellence, with final winners scheduled to be announced at the OLA 2008 in Nashville, Tenn., this November.

Nominees were named in the following categories: Dress Frames, Safety Frames, Specialty Frames, Children's Frames, Lens Design, Lens Materials and Treatments, Marketing, Surfacing Equipment, Surfacing Material & Tools, Finishing Equipment, Finishing Material & Tools, Lens Treatment Equipment, and Accessory Products.

For a complete list of the OLA Awards of Excellence nominees, visit

VisionMonday.com.

“These products and companies have been selected by OLA members to be considered for an award. This alone is high praise for each of these products,” said Barney Dougher, OLA President. “OLA believes it is important to recognize the ophthalmic industry suppliers who have made an outstanding contribution to the laboratory community and allied professions. An OLA Award of Excellence is the most prestigious award our industry offers,” said Dougher.

This begins the “campaign” phase of the program, where each final nominee company can “lobby” their customers for their votes, according to an announcement from the OLA. The award process will enter the voting stage in the fall. Ultimately, OLA members determine the award winners. In late September, every OLA lab member will be sent a ballot, and each company has one vote to cast for their choice. Final winners will be announced at the President's Banquet on Nov. 8 at The OLA 2008 in Nashville, Tenn.

Optical Resources Relocates to Indianapolis—

Optical Resources has moved its corporate office to Indianapolis, Indiana and implemented new operating systems. The company's new contact information is:

5515 E. Washington St.

Indianapolis, Ind. 46219

(Mail)

P.O. Box 19441

Indianapolis, Ind. 46219

Tel: (317) 522-0872

Fax: (317) 522-0873

Optical Resource's key personnel include:

Virginia Haskins

Director of Sales & Customer Service Dept.

Direct Line: (317) 522-0871

Email:

[email protected]

Regional Manager of Sales & Customer Service Direct Line: (320) 492-9253 Email:

[email protected]

Vickie Sullinger Office Manager/Bookkeeping Direct Line: (317) 522-0870 Email:

[email protected] or

[email protected]

Josh Halstead

VP/General Manager

Direct Line: (317) 522-0872

Email:

[email protected]

Dan Halstead

Operations Manger

Direct Line: (317) 522-0872

Email:

[email protected] | |