By Seth J. Bookey

Contributing Editor

|

RETAIL DISPENSARY

SPECIAL SAFETY SECTION |

First and foremost, seeing safety eyewear clients on the ECPs' premises has led to those clients also patronizing the same ECP for non-work eyewear, and referring family members and others to the same ECP for comprehensive eyecare.

|

| An optician at one of Lafreniere's two locations in New Hampshire fits a Rx safety eyewear patient. |

VM recently spoke with ECPs for whom Rx safety eyecare represented anywhere from less than 1 percent to 20 percent of their total business, and for them, the benefits of this niche have outweighed the initial start-up pains, pursuing clients, and then only receiving a dispensing fee.

Something Extra

Even when a safety eyewear client comes in with a set spending limit and no one additional to refer, ECPs have found that patients are willing to pay for add-ons. Today, polycarbonate is the standard safety lens material covered by most safety programs, but cli�ents today are willing to pay for progressive lenses, photo�chromics, or AR lenses out of pocket, especially if they are already using these premium products in their non-work eyewear.

Charles Lafreniere of New Hampshire's two-location Lafreniere Eyecare said that "patients appreciate looking better" and that during the past five years, a trend toward nicer styling has safety clients saying 'I wouldn't mind wearing them [safety glasses] outside of work.'" He also noted that today's safety eyewear styles have moved from mostly zyl to metals (including titanium) and even rimless.

Also, "flat-tops have dropped from 70 percent [five years ago] to 30 or 40 percent today," Lafreniere told VM. "They have to pay extra for PALs, but people generally think the out-of-pocket cost [about $50] is worth it."

Steve Baker of Korrect Optical, with two locations in Louisville, Ky., and one in Clarkson, Ind., also noted how safety frames styles have caught up with dress eyewear designs. "The frames have come a long way and the safety eyewear manufacturers have improved their designs. They realize that if they have frames that look like the best-selling retail styles, their safety eyewear will sell better. This has produced more business for them, and for us, and helped create more acceptance for the end-users as well."

Baker has also noticed that most companies are covering the additional cost of progressive lenses for their employees. "More and more people are wearing PALs, and employers are realizing they need to provide them," Baker said. He also noted the predominance of polycarbonate as the lens material of choice. "We've trained our customers to use polycarbonate. The clients are better trained in these issues as well, and safety advisors are telling them to order polycarbonate also."

|

| Rx safety eyewear is given its own specialdisplay at Four Seasons Eyecare in Minneapolis. |

Ease of Operation

Another benefit of working with corporate clients on prescription safety eyewear is reduced paperwork, along with guaranteed recalls. Most companies complying with OSHA standards pay for initial and replacement products directly to labs, so managed-care plans are no longer involved. While some companies only replace lenses every year and frames every other year, most won't wait longer on frames. As Casey Conrad of Heartland Optical, Lincoln, Neb., noted, it simply isn't safe to put a new compliant lens in a five-year-old frame.

Additionally, no matter which lab an ECP works with, the compliance issues (e.g., changing ANSI and OSHA standards and COLTS certification) are taken care of by the labs. This allows ECPs to concentrate on the dispensing, upselling to products not covered by the safety program, and cultivating referrals. Working with corporate clients' safety directors and human-resource directors helps simplify dispensing choices, and for ECPs who limit safety brands and work with just one lab, in-store displays and dispensing gets that much simpler as well.

'Reversing' the Road to Success

|

| Casey Conrad |

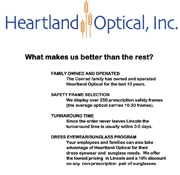

Casey Conrad, CEO and president of Heartland Optical, is ready to take the prescription safety optical marketplace in Lincoln, Neb., by storm. This retail optical lab started to pursue the safety niche seriously in 1990, when Conrad's father, Ronald, took over majority interest in what was then a decades-old, wholesale-only optical lab.

With about 60 safety eyewear accounts under its belt, Heartland Optical is planning to open a larger retail dispensary in December, with a grand opening in January 2006. Conrad told VM that the new 1,000-square foot space will start with one OD lane but will have room to expand to a total of four exam rooms. Currently, Heartland Optical sees patients in a small safety dispensary carved out of part of the company's warehouse-like space in a part of town that's slated for redevelopment.

|

| Heartland Optical of Lincoln, Ne., greets prospective clients with a welcome letter along with information about its Rx safety eyewear program. |

|

"It's like a cave! We have no windows!" Conrad joked. The new location will be three blocks away from the current dispensary, on a piece of land near an MD, a dentist and a federally funded health-care facility.

While other competing ECPs saw this niche as a hassle, "We are expanding," Conrad told VM. "We have a total reverse problem. We have the people, but not the services. We want to create a larger dispensary, have ODs who give eye exam, and to handle managed-care plants. We've never been able to have major insurance carriers."

Despite its less-than-traditional dispensing environment, Heartland has managed to grow its safety prescription eyewear business by focusing its efforts in a personal way. When Conrad joined his father's business in 1993, he set about bringing in local accounts for safety dispensing. The safety accounts are a mix of large companies with thousands of employees to small mom-and-pop companies. Conrad and his brother Thomas have been the main sales reps for these accounts.

While a mixture of accounts has worked for Heartland, Conrad said that "we try to pick up the smaller companies because we think they're the most loyal." Conrad reads the local papers and talks with current customers. "It's a really grassroots way of growing business. It's created a tight group of consumers we can count on for the foreseeable future. It's mostly calling and drumming up interest."

While Heartland still relies on patients coming in with an Rx, and tends not to do on-site exams, the company does call on clients to meet with safety directors and human resource managers to discuss compliance with OSHA regulations, as well as bring in price lists and information brochures from Prevent Blindness America and the American Optometric Association.

"They can take our information and change policy pretty quickly. When you work closely with so many companies, your personal relationships forge nice communication over the years."

Being an independent retail optical lab in a territory surrounded by VSP labs and Varilux distributors, Heartland has had to become a "company built on niches." Conrad said the "two Vs" considered Heartland too small to work with.

"Through the 90s we came to the realization that we had to work with safety. Insurance was a staple for Nebraska practices. They wanted to work with labs that would work with insurance." Heartland also found that once patients liked Varilux PALs, it was hard to get them to switch.

Consequently, Conrad pursued personal safety Rx patients in addition to corporate accounts. He has set up a booth at motorcycle shows to promote Rx sunwear, since motorcycle shops tend to only sell plano sunwear. "Lincoln is a big bicycling city and we're going to target that niche with sports and sunwear lines."

Conrad counts U.S. Safety and Essilor his safety Rx competitors, but points out that they "sell mass quantities but don't see the faces. They don't have a shop or interact with the customers."

While Heartland has gone through some "growing pains"--some ODs have dropped using their wholesale lab services--Conrad said it's been years since they've lost a safety client, and that getting a flow of patients coming to them helps sell dress, sport and sunwear as well. "At the heart of it, we're a wholesaler. These outer niches pretty much funnel people into the heart of our business, which is a lab."

Finding Success Locally

Charles Lafreniere, OD, who has offices in Sommersworth and Durham, N.H., has been working with prescription safety eyewear for 12 of the 14 years he has been in practice. Early on, he went to major industrial companies in his immediate area, like General Electric. "We heard through the grapevine that they were looking [for someone to provide] safety eyewear [services], and we were within a third of a mile from their plant."

|

| Charles Lafreniere |

In the early 1990s, almost half of Lafreniere's business came from his account with General Electric. "Our plan was set up for both safety and personal eyewear benefits, as well as exam benefits. That drove patients to us in a big way. It was easy to offer them personal eyewear--this meant less wear and tear for the safety glasses outside the work environment," he said."Before we started this, I never held safety eyeglasses. During the first few months, we learned as much as possible about the different types of jobs people were performing," Lafreniere said.

Today, Lafreniere Eyecare has about half a dozen safety eyewear client companies of differing sizes. All exams are done at Lafreniere's two offices rather than on site, since his clients are close enough to reach either office. For one client, Lafreniere is one of several ECPs the client company uses to dispensing safety eyewear over a wider geographic area.

Lafreniere's office manager sets up safety eyewear packages and a customized safety eyewear plans for each company. Two opticians are schooled in the nuances of safety eyewear, so Lafreniere himself doesn't have to get too involved with the administrative aspects.

Lafreniere has safety eyewear displays set up in both offices, showing dozens of styles. He deals mainly with AOSafety, but also with Hoya for individual, noncorporate clients, who include, for example, people who do woodworking, auto repairs or landscaping. He also keeps sports safety eyewear on display as well.

Forging Closer Relationships

Don Sealock, OD, owner of the nine-location Four Seasons Eyecare based in Minneapolis, has been in practice since 1986 and has always been in�volved in prescription safety eyecare.

"It's a valuable tool for those beginning in practice, and it's a good opportunity to solicit more business from [the safety Rx patient's] family and co-workers."

Sealock told VM that his nine offices work with about 75 to 100 prescription safety clients, which accounts for about 5 to 6 percent of his business. Four Seasons has three offices in metropolitan Minneapolis and the remaining offices are located in well-established commuting cities nearby. All the clients are within a 90-mile radius of Four Season's nine locations, each of which feature a safety section.

|

| Don Sealock |

Sealock first developed his safety eyewear practice by personally soliciting companies with fewer than 50 employees and proposing comprehensive eyecare that included meeting Rx safety needs. Currently, Sealock has a mixture of corporate clients, from the smaller companies he initially approached--like cabinet makers--to larger outfits such as the statewide Excel Energies, among others. In addition to dispensing routine safety eyewear annually or every other year, Sealock's offices also treats emergency ophthalmic cases as well. "That's where the downstream revenue comes in."

Sealock notes that because safety eyewear has a longer turnaround time, "you need an excellent working relationship with the lab so you can meet the goals and expectations of the patients." Ninety percent of Four Season's safety eyewear jobs go to Twin City Lab. To speed up total turnaround time, all nine Four Seasons locations transmit prescriptions to the lab electronically, and all offices use electronic billing as well.

Making a Niche Profitable

Like many other independents, Drs. Little and Schmidt Vision Source of Mandan, N.D., sought out the prescription safety eyewear niche to grow their practice. Dan Little, OD, has been in practice since 1979 and he has made safety part of his practice since 1985.

Little's practice includes mostly larger corporate clients, including Montana Dakota Utilities, Minnkota Power, Burlington Northern, Baukal Noonan, and Tesoro. Because they are situated in a more heavily industrial area, Little faces some competition from other ODs also looking to grow this niche. "You don't make a lot [of money] on safety, but you hope for side business," Little told VM.

|

| Dan Little |

Luckily, at Minnkota Power, a coal-fired electric generating plant, and Baukal Noonan, a coal mining company, there are 300 employees at each company to be fitted with prescription safety eyewear.

As a way of making the dispensing as easy as possible for its corporate clients, Little and Schmidt have a satellite office in Center, N.D., where many of the plants are located. A selection of safety eyewear is displayed at both locations, as is some Wiley X sunwear for sports safety consumers.

Little has noticed a lot of changes in safety eyewear, as polycarbonate lenses now make up 95 percent of the Rx safety eyewear he dispenses. "There is very little glass safety eyewear now, and fewer plastic lenses also. Almost every prescription is available in polycarbonate now."

Making Safety 'Individual'

While fitting prescription safety eyewear does differ somewhat from everyday eyewear, the dispensing basics still apply. At Family Vision Clinic in Houma, La., optician Joyce Dayton, who works for owner Lawrence Breaux, OD, noted that "regardless of who's paying, we treat them as individuals." During her 18 years at this 25-year-old practice, she has seen new patients referred "as individuals grow within the [safety client] company."

Dayton has seen safety dispensing at Family Vision Clinic grow tremendously, with 15 percent of the dispensary's business coming from safety clients. While some safety eyewear is for individuals, she said 95 percent of it comes from corporate clients, which include Haliburton, Bell South, Barker BJU, Baker Atlas, and Gemmeco. Most of the companies are in the oil business, but Dayton also sees a lot of patients in the boating industry and she noted, "safety eyewear is becoming mandatory for machnists."

The practice has about 400 safety patients--half of whom come from Haliburton--and does 25 to 40 safety Rx jobs a month.

Family Vision provides companies with a wall chart of available frames, and does onsite vision screenings for visual acuity, depth perception, and color blindness--with follow-up care at the office. Dr. Breaux often does safety presentations on site as well. One employee at Family Vision is now responsible for liaison work with smaller safety clients (10 to 100 employees), while larger clients have safety department managers detailing coverage plan limits.

While Family Vision does have a separate safety area, all patients are shown all available products, regardless of whether the safety plan covers them. "We want them to have whatever is best, optically," Dayton said.

While the practice has worked with several safety eyewear suppliers over the years, it currently works with AOSafety because "they were easy to deal with and efficient" and because it was more efficient to work with just one company. Dayton also said that when the ANSI standard for safety eyewear changed, "they made it easy."

Cornering the Market

Being in a heavily industrial area can make developing a successful safety eyewear niche easier for an ECP. According to Sandy Pustejovsky, office manager for R. Paul Dickey, OD, in Port Lavaca, Texas, safety eyewear, which has always been part of the 20-year-old practice, accounts for 20 percent of its business.

The dispenser does about 20 to 30 safety eyewear jobs per month with just three large chemical company clients, which include Dow and Formosa. "Business has bee stable," Pustejovsky told VM, "We have all the plants in this area." During the past five years, she has seen the companies grow, which has resulted in the practice seeing even more patients.

By only doing eye exams in the office, the practice has also been able to bring in the residual business from the safety clients' families. The practice works with the safety departments at the companies, which set the standards and payment limits with which Dickey's practice must operate.

Dickey's practice works with two labs when it comes to safety eyewear jobs--Orco in Dallas, and Aero Safety. Unlike managed-care clients, working with safety patients has meant less paperwork and administration. "We do the dispensing and ordering, the labs bill the companies," Pustejovsky said. "We get the dispensing fee when the employees come in with the proper ID numbers and authorizations from their companies." Because working in chemical companies causes a lot of wear, employees typically get new glasses annually, and despite spending limits, some employees are willing to pay out of pocket for photochromic or progressive lenses.