| New

Products |

|

| |

|

Tech

Talk |

|

SURFACING ROOM PROTOCOLS, Part 1

The first step in minimizing spoilage in the surfacing process is following routines. Surfacing room protocols can greatly reduce spoiling risk, and make tracking the cause of spoilage easier. Here are some protocols your lab should consider using, if you’re not already doing so.

CALIBRATION SCHEDULE

Calibrating equipment routinely reduces the risk of error. Calibrate all equipment according to manufacturer guidelines. Check calibration throughout the day on a regular basis. In addition, routine maintenance, including lubrication must be followed Make a schedule and stick to it.

TEAMWORK

Create a team atmosphere for employees. From the highly skilled to least skilled worker, strive towards a cooperative personnel environment, which will lead to people checking each other’s work, thus minimizing spoilage caused by human error.

COME CLEAN

Dirt, dust, debris and particles can damage lenses and sophisticated technology. Follow regular cleaning routines for the facility and the machinery daily. Remember it’s not just the equipment itself, but the benches, shelves, walls and floor that require daily cleaning. Dust and debris accumulates, and if it is in your lab, it will find its way to the lens and cause scratches and other forms of spoilage. You may want to consider the installation of air filters, which will enhance the cleanliness of the lab environment.

BE ORGANIZED

Lens inventory, lap tools, blocks, surface-saver tape and pads are specific items for specific jobs. Keep these tools and products well organized and make sure the lab staff understands the system.

ROOM TEMPERATURE

Keep the room temperature of the surfacing lab consistent. Is your heater too hot in the winter? Is your air conditioner too low in the summer? Fluctuations in room temperature increase spoilage. Heat and humidity affects the equipment functioning, even causing lens materials to expand slightly, but often enough to alter parameters. Lab managers recommend a lab temperature between 60 and 70 Degrees. At the end of the day, you may want to keep the lab cooler, to offset the excess heat caused by hours of production. |

| |

| The Working Lab |

|

Boosting Efficiency With Remote Order Entry

Remote Order Entry can change the way business is done. When orders come in hand written with the frame attached to the Rx, it can be a big labor guzzler for the lab in the front office. Opportunities for error are rampant. With remote order entry, the eyecare professional’s (ECP) office enters the prescription. This one step increases the efficiencies in the front office for the laboratory. Now, imagine that the customer is able to enter all jobs themselves, there is less error and with many systems they can track where the job is in the lab. The customer (ECP) is able to actually be in charge of the information for their patient—identifying delivery times and managing expectations. As laboratories increase the number of jobs that are received and processed via remote order entry, processing can actually become more efficient. Sound ridiculous? Sound scary?

Walman Optical, for example, has been working with remote order entry to improve the efficiency of their front office, reducing the time their customer service representatives spend trying to decipher prescriptions, call the doctor’s offices, hunt down information and keep track of where the orders were in the process. They encourage remote ordering; however, they do not start processing until the frame comes in and is matched with the job.

There was a time when it was thought that remote ordering would be beneficial because the job could be surfaced and wait for the frame. However, as identified in the May Lab Advisor Rx Files, the frames that are sent may or may not have been properly identified or measured or traced.

Let’s face it; spending time on jobs that will not go out is inefficient and unnecessary. The problem wasn’t the lack of jobs in the finish room. It was turnaround time. Remote ordering improves turnaround time by improving the accuracy of the information and reducing front office time to start the job and prepare the lab by having the lenses ready for processing. Remote ordering also reduces the amount of time front office personnel spend handling repetitive phone calls and tracking jobs. Customer service can now focus on what they do best—taking care of customers.

The technology will increase the efficiency in the laboratory by being prepared and efficient in the beginning of the process. That alone will increase production and turnaround time. Walman has seen a decrease in processing time and an increase in turnaround time of the jobs that go through the remote processing link.

Know what the real problem is, or as the quality improvement gurus would say – be sure you know the root cause before you buy the solution.

—Linda Little

Linda Little is an optical industry veteran and writer who specializes in laboratory and technical topics. She can be reached at (214) 215-5453, or at

[email protected]

|

|

|

|

Accounting for Discounts and Warranty/Redo’s

Whether comparing performance from year to year, making equipment purchase decisions or determining the value of the lab for estate planning or a sale, it is important to know the business’ accurate profitability and associated liabilities. Exposure for future events should be estimated through reserves and allowances in order to determine an accurate financial picture. Reserves and allowances, such as allowance for doubtful accounts, vacation accruals, and inventory obsolescence, are well documented in accounting procedures. In this column, we will explore the calculation of discount allowances and reserves for warranty/redo’s to determine their exposure and then explain how they impact profitability, as they are unique but highly relevant to optical labs. Whether comparing performance from year to year, making equipment purchase decisions or determining the value of the lab for estate planning or a sale, it is important to know the business’ accurate profitability and associated liabilities. Exposure for future events should be estimated through reserves and allowances in order to determine an accurate financial picture. Reserves and allowances, such as allowance for doubtful accounts, vacation accruals, and inventory obsolescence, are well documented in accounting procedures. In this column, we will explore the calculation of discount allowances and reserves for warranty/redo’s to determine their exposure and then explain how they impact profitability, as they are unique but highly relevant to optical labs.

Discounts—Unfortunately, discounts have become a part of the wholesale optical lab business and need to be properly accounted for. Discounts do have a real cost and liability associated with them. Discounts reduce revenue to arrive at net sales; at the end of any period, accounts receivable should be reduced by potential or likely discounts yet to be taken.

Generally, the discount can be estimated by determining the average monthly discount percentage to gross sales and multiplying that percentage by gross sales for the most recent month. Gross receivables show you what your customers owe; the discount allowance shows what you owe your customers.

Warranty/Redo’s—Warranty/redo’s represent one of the most significant, and yet often unaccounted for, costs to the lab. They come in many forms from manufacturer’s, scratch, AR, non-adapt, doctor redo’s to lab redo’s. A good way to determine the lab’s warranty/redo liability to customers is to use recent historical units-sold experience percentage for each type of warranty/redo times cost of goods sold for the year, times one half of the warranty period. For example, if you have a two-year scratch coating warranty and typically 2 percent of total units are returned and cost of goods sold is $3,360,000, then (2 percent of units x 3,360,000 x 1[1/2 of 2 years]) = $67,200 is the amount of liability. This means the lab owes approximately $67,200 to its customers for this two-year scratch warranty. A similar calculation would be completed on every form of warranty to determine the total.

Warranty/Redo Exposure—These allowances and reserves can also have a significant impact on profitability. If discount exposure increases from ($50,000) at the beginning of the period to ($60,000) at the end of the period, costs should be increased by $60,000 - $50,000 = $10,000. The result, good accounting practices translate to an accurate reflection of how your business is actually performing. Absent accurate accounting procedures, the lab owner is only getting part of the actual operating and financial results of their business.

—Thomas F. Puckett, pictured here, managing director & CEO, HPC Puckett & Company (

[email protected]) and Jason A. Meyer, senior vice-president, HPC Puckett & Company (

[email protected]). Based in San Diego, Calif., HPC Puckett & Company specializes in mergers and acquisitions of wholesale optical laboratories. —Thomas F. Puckett, pictured here, managing director & CEO, HPC Puckett & Company (

[email protected]) and Jason A. Meyer, senior vice-president, HPC Puckett & Company (

[email protected]). Based in San Diego, Calif., HPC Puckett & Company specializes in mergers and acquisitions of wholesale optical laboratories.

|

|

| |

|

|

|

Surfacing Spectralite Velocity Surfacing Spectralite Velocity

Bill Heffner at FEA Industries reports that his lab has added a new step in processing Spectralite Velocity which has drastically reduced the number of surface waves on low plus and minus lenses.

Here at FEA Industries, we are using Loh equipment for surfacing. [PRA Blockers, V-Pro Generators, and Toro-X cylinder machines.] Before we block any Spectralite Velocity, we put the blanks in to our A/R degassing oven for a period of four hours.

Basically, the oven is forced air drying chamber that circulates warm air at 60 Degrees C, or 140 Degrees F. After the lenses are removed from the oven, they are blocked within a half hour. After blocking, they are allowed to cool for 1.5 hours in room temperature. Do not force chill the lenses by using cold water. Then surface as normal. Basically, the oven is forced air drying chamber that circulates warm air at 60 Degrees C, or 140 Degrees F. After the lenses are removed from the oven, they are blocked within a half hour. After blocking, they are allowed to cool for 1.5 hours in room temperature. Do not force chill the lenses by using cold water. Then surface as normal.

Why does this seem to work? After discussing the lens manufacturing process with AOSola Technical, they indicated that the Spectralite Velocity lenses are half cured at the factory before they are sent to Transitions Optical. After the coating process is completed, Transitions then cures the lens the remainder of the way. When we place the blanks in the A/R degassing ovens, we are actually drying the lens which makes it more brittle, thus a harder, more rigid material to surface.

I have done drop ball testing on these lenses with 1.5 centers to double check that we did not adversely affect impact resistance. Since we have started this new procedure, our spoilage went to almost zero [we still have people in the lab].

From time to time, I have found this technique also works when we wave high minus plastic Transitions lenses.

—William Heffner, III, chief executive officer, FEA Industries, Morton, Pa. |

|

| |

|

|

Debbie Mullins of Cherry Optical in Melvindale, Mich.

Debbie Mullins just might be the only person in the optical industry that really started working in “the business” when she was 12—the excuse the rest of us use when we realize that claiming 25 or 30 years in the industry ages us quickly. I couldn’t help but chuckle when she told me. However, her task of washing the blue off glass lenses would coincide with that time period, so she’s legit. Debbie Mullins just might be the only person in the optical industry that really started working in “the business” when she was 12—the excuse the rest of us use when we realize that claiming 25 or 30 years in the industry ages us quickly. I couldn’t help but chuckle when she told me. However, her task of washing the blue off glass lenses would coincide with that time period, so she’s legit.

After 26 years, she’ll be the first to tell you she loves it. Who better to show her the ropes but Richard Cherry, her father. “I went to college to be a lawyer, but I missed the optical business,” Debbie explained. “I really liked working for my Dad, so I came back.”

Debbie has worked in every part of the lab from answering phones and pulling lenses to surfacing and finishing. Three years ago, she was promoted to office manager for the business. She oversees all aspects of day-to-day operations and all aspects of marketing from pricing to advertising and all computer information and updates that their customers need.

Not one to sit still, she decided she wanted to be ABO-certified one year ago. On June 21, she met her goal, receiving positive test results and Board certification. “I feel good about this achievement,” Mullins commented. “The certification is recognition of having the knowledge of optics and the knowledge of processing.” Mullins has already contacted ABO about pursuing advanced certification and master’s achievement.

One of Mullins’ successful marketing events is “Your Eyes University.” The event is free to anyone who wants to attend. The all-day program is social, offering an opportunity for doctors and their staffs to network with their peers as well as offering educational classes and NCLE accredited classes. Over 500 people attended this year and the amount of vendor participation doubled. “I believe in getting involved, learning and understanding the new technology, and sharing that opportunity with our customers,” she explained.

“My goal is to make sure the day is planned to benefit our customers with opportunities for learning from their peers, finding out what is going on in the industry, learning from vendors and receiving credit for their time.” As someone who is very focused on education herself, Mullins is the first to tell you she learns everyday. Now she is diving into the business side of running a lab as well as keeping up with the lab operations and technology. “I really love the industry,” she adds. “I can’t remember meeting anyone who wasn’t nice or willing to help me. It’s like one big family.”

And to keep the family involved, Debbie’s three daughters are now working there during the summer, the oldest works part time while attending college. Her husband also works in the laboratory business. As we end our conversation, Debbie tells me she is off to Portland for a meeting with DVI. Her excitement is infectious. I was energized too – it was refreshing to speak with her and experience her enthusiasm as the next generation in the independent lab business.

—Linda Little

|

|

| |

|

|

Jim’s Optical Turns on Cruise Control to Boost Business

|

|

Dr. Wilson and Janet Vaughn are pictured here, with Vaughn holding a Winner’s Certificate from Jim’s Optical Service. |

“Jim’s Optical Service feels as an optical lab, we need to give back to those who work hard for their patients, not only doctors but assistants and office personnel. This is why we are committed to doing ongoing promotions the rest of the year,” said Genise Williams, marketing and educational representative for Jim’s Optical Service, a 28-year-old full-service wholesale lab in Modesto, Calif.

The lab’s most recent promotion, which was co-sponsored by Transitions Optical and Carl Zeiss Vision, awarded a cruise for two to Ensanada, Mexico plus $500 in spending money. The lucky winners were Teresa Leon, an employee in Dr. Richard Portillo’s optometric office in Modesto, and Janet Vaughn, an employee in Dr. Bernard Wilson’s optometric office in Modesto. Both Leon and Vaughn are long-standing employees at their respective offices; Vaughn is a former board member for San Joaquin Optometric Society Symposium.

Jim’s Optical’s next promotion will run from October through December, the "Do You Feel Lucky" Reno bus trip contest. "We take 20 winners and their guests to Reno for the day and have a really great time. This is our most popular promotion," explained Williams. Although Jim's Optical is committed to offering all their accounts an opportunity to win and their manufacturers an opportunity to participate, the real bottom line for these promotions has been selling more progressives and add-ons. The result has been a doubling of jobs per day over three years, from 100 per day to 200 per day. Jim’s Optical’s next promotion will run from October through December, the "Do You Feel Lucky" Reno bus trip contest. "We take 20 winners and their guests to Reno for the day and have a really great time. This is our most popular promotion," explained Williams. Although Jim's Optical is committed to offering all their accounts an opportunity to win and their manufacturers an opportunity to participate, the real bottom line for these promotions has been selling more progressives and add-ons. The result has been a doubling of jobs per day over three years, from 100 per day to 200 per day.

|

| |

|

|

| Getting ready to tee off at the Eastmoreland Golf Course are (l to r) Dan Lundberg of DVI, Paul Massey of Pech Optical, Mario Pageau and Daniel Raby of Lunettaire New Look and Tim Christ of Midland Optical. |

| |

|

| Faith Kerr (l) and Theresa Sawyer (r) of Vision Systems of Georgia enjoy a workshop presentation. |

| |

|

| DVI president Gordon Keane (r) presents a DVI Pioneer Award to Paul Massey (l) of Pech Optical Corporation in Sioux City, Iowa for 20 years of business with DVI. |

DVI Hosts 2007 Vision Workshop—Digital Vision, Inc. (DVI) welcomed 115 participants representing 67 optical laboratories from across the U.S. and Canada to its 2007 Vision Workshop. The workshop is held to update customers on the latest improvements in DVI’s Vision software. The event kicked off with a golf scramble at Eastmoreland Golf Course on June 14 and the workshop followed on June 15 and 16 at the Embassy Suites Hotel in downtown Portland, Ore.

The workshop covered many new features of the Vision software, including sessions on the RxWizard, the new “combobulator” software, and other customer service improvements. Gordon Keane presented DVI Pioneer Awards to 20 year customers Craig Caudill of Vision Craft, Inc. in Yakima, Wash., Paul Massey of Pech Optical in Sioux City, Iowa, and John Wolfe of the Optical Lab at Park Nicollet in St. Louis Park, Minn. Warren Meyer of Perfect Optics and Ray Knoll of Hoya Vision Care received special Optical Good Fellow Awards.

The workshop concluded with a roundtable luncheon where customers and DVI employees worked together to brainstorm new features to be integrated into the Vision software. Suggestions made by customers at the roundtable discussions are an integral part to DVI's software development.

Essilor Expands U.S. Prescription Lab Network—Essilor of America, the U.S. subsidiary of Essilor International, has acquired a majority stake in Sutherlin Optical Co. and purchased the assets of Dispensers Optical Service Corp.’s safety prescription division.

Located in Kansas City and Joplin, Mo., Sutherlin Optical is a prescription laboratory and distributor of the Varilux brand, with $13 million in annual revenue and 75 employees. Its customers are located mainly in Missouri and Kansas. The lab is co-owned by Steve Sutherlin, Mike Sutherlin and John Sutherlin. It ranked 12th among Vision Monday’s Top 25 Independent Wholesale Labs in 2006.

Dispensers Optical Service Corp.’s safety prescription division is a leading manufacturer of occupational eyewear. Based in Louisville, Ky., it generates $5 million in annual revenue, which accounts for about 50 percent of Dispensers Optical Service’s total revenue; the remaining 50 percent is generated by the company’s defense division. Charles Arensberg, president and chief executive officer of Dispensers Optical Service, was the majority owner of the safety prescription division. Arensberg and other key executives will remain with the defense division.

Summit Optical Affliates with MidSouth, Diversified—Summit Optical, an independent, full-service ophthalmic laboratory located in Nashville, Tenn. has formed an affiliation with MidSouth Premier Ophthalmics and Diversified Ophthalmics.

“Our affiliation with Summit Optical allows us to meet our goal of being a single source provider of both soft contact lenses, gas permeable contact lenses, and prescription eyewear,” said Andy Jackson, chief manager of MidSouth, who will serve as Summit’s new president. “In addition, customers will be pleased to know that Summit’s experienced staff will remain on board to meet their ophthalmic needs.”

“It is our intent to use the combined business experience and resources of MidSouth and Diversified to enhance Summit’s ophthalmic lab capabilities,” added Dr. Ronald Cooke, OD, chief executive officer and CEO and president of Diversified. “Our focus will be on helping Summit Optical deliver high quality ophthalmic products with a very short turnaround time.” |

|

|

|

Teflon Clear Coat FSV

Manufacturer: Carl Zeiss Vision

Description: Range extension of Zeiss’ Clear Coat finished single vision (FSV) product lines.

Availability: Sphere range of +4.00 to -6.00D, to a -2.00 cylinder in both polycarbonate and CR-39™.

Features: Latest-generation Teflon Clear Coat Lenses performance. Very low visible reflectance for maximum clarity; super-hydrophobic and oleophobic top coat provide easy cleaning for the life of the prescription; scratch resistance equivalent to a premium hard coat.

(800) 358-8258

www.solateflon.com |

| |

|

Crizal Sun Tints

Manufacturer: Essilor of America

Description: Crizal Sun lenses line extension. Grey, grey green, brown and black offered in four grades: 0 to 3. Lens material options expanded to include polycarbonate and high-index plastic.

Features: Crizal Sun lenses employ Crizal Alizé technology. The front side of a Crizal Sun lens has the Alizé hardcoat and super-hydrophobic layers. The back side of the lens contains both of these layers, and also includes the Crizal Alizé anti-reflective layer. Crizal Sun is integrated into the lens, so it will not wear or peel off over time, according to Essilor.

Polycarbonate and high-index lens choices provide built-in ultraviolet (UV) protection. The UV protection offered by Crizal Sun lenses is based on the lens material choice. Crizal Sun lenses are comparable to lenses with Crizal Alizé in both performance and price and come with the proprietary Pad Control System. Crizal anti-reflective coatings from Essilor reduce glare and protect lenses from scratches, smudges, dust and dirt.

(800) 366-6342

www.essilorusa.com

|

| |

|

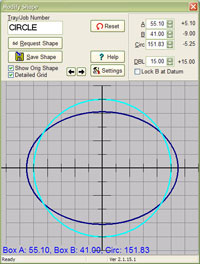

Modshape

Manufacturer/Distributor: Concat Services

Description: Software that creates the ability to modify and save any frame shape or pattern. Running on a Windows PC, ModShape allows users to change any shape that can be retrieved from their lab system. Jobs processed through ModShape request the data from the lab system by tray or job number.

Features: View and verify shapes. Change A, B and/or circumference; adjust DBL; lock B at datum line. rotate and adjust axis; original vs. modified shape comparison; create multiple eye sizes for one shape. Easy to install; can be used with all VCA-compatible lab management host software systems.

Availability: 30-day free trial

(877) 524-7265

www.modshape.com

|

| |

|

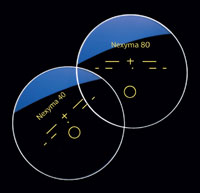

Rodenstock Nexyma 80 and Nexyma 40

Manufacturer/Distributor: Optical Distribution Corp.

Description: Intermediate lens (Nexyma 80); near lens (Nexyma 40)

Features: Nexyma 80 has an extended visual area from reading distance to room distance making an ideal computer lens. Nexyma 80 has two separate designs. Digression type A is for additions up to +1.75 and Digression B is for additions from +2.00. The Nexyma 80 provides patients with a relaxed head and body posture for general intermediate ranges.

Nexyma 40 is designed for reading, handcrafts and all close-up tasks. It has a large near area of wide vision, giving patients vision comfort and a relaxed posture for near vision. There are no special fitting techniques required for the Nexyma 40 or the Nexyma 80. The lenses should be ordered with normal progressive lens measurements. The Nexyma is designed with position of wear technology.

Availability: Nexyma 40 and 80 lenses are available in standard 1.50-index plastic and can be ordered through authorized wholesale laboratories throughout the U.S.

(888) 407-EYES (3937)

www.rodenstockusa.com

|

| |

|

ShoreView Mini

Manufacturer/Distributor: Shore Lens Co.

Description: Short-corridor progressive lens

Features: Wide distance zone. Recommended minimum fitting height 14mm. Easy to fit and adapt. Optimal for emerging presbyopes or new PAL wearers.

Availability: ShoreView Mini is available in 1.50 clear plastic and 1.56 photochromic in ray. Additional materials to be released later in the year.

(888) 547-4802

www.shorelens.com

|

| |

|

|

|

In This Edition...

|

DOLLARS & SENSE |

| Accounting for Discounts and Warranty/Redo’s |

|

THE

RX FILES |

| Surfacing Spectralite Velocity |

|

FOCUS

ON… |

| Debbie Mullins, Cherry Optical |

|

NEWS

TO USE |

| Jim’s Optical Turns on the Cruise Control |

|

LAB

NOTES |

|

Essilor Expands U.S. Prescription Lab Network

Summit Optical Affliates with MidSouth, Diversified

DVI Hosts 2007 Vision Workshop |

|

TECH

TALK |

| Surfacing Room Protocols, Part 1 |

|

THE WORKING LAB |

| Boosting Efficiency with Remote Order Entry |

|

Buying Group & Lab Association News |

|

Gulf States and J&J Optical Joins OSC

Toledo Optical Joins Global Optics

Global Holds Annual 2007 NSM |

|

| |

|

•Subscribe

to Lab Advisor

The monthly update for Optical

Laboratory Owners and

Managers

•

Forward

this issue of Lab Advisor to a friend or

colleague

•

Print

this issue of Lab Advisor

•

Stay

on top of optical industry news!

Subscribe to our other

e-newsletters:

•

VMail Extra

•Sun Advisor

•

Business Essentials

If you have lab news or want to share information about technical topics,

please contact us at

[email protected]

Or

Andrew Karp,

Editor-in-Chief

[email protected]

For additional articles of interest about labs, go to

LabTalkonline.com

|

| |

|

| |

|

Buying Group & Lab Association News

Gulf States and J&J Optical Joins OSC—Optical Supply Co-Op (OSC), a wholesale laboratory organization based in Pelham, Ala., is adding Gulf States Optical Labs and J&J Optical to its network.

Gulf States Optical Labs, located in Jefferson, La., is owned and operated by Pierre Bezou. The lab is a Varilux distributor and has been in business for over 62 years. J&J Optical, located in Paradise, Calif., is owned and managed by John and Jerry Haigh. A recent re-engineering of the lab includes a Zeiss AR coating facility.

Toledo Optical Joins Global Optics—Global Optics, the Green Bay-based independent wholesale laboratory organization, is adding Toledo Optical of Toledo, Ohio. Founded in 1947, Toledo Optical is led by Irland Tashima, who serves as president. It ranked 22nd among independent labs in Vision Monday’s 2006 Top Labs Survey, with estimated net sales of $6.9 million. The lab primarily serves the Ohio and Michigan markets. Transitions Optical named Toledo Optical its U.S. Lab of the Year in 2006 and 2003.

“We are excited to have Toledo Optical join our team and look forward to working with their outstanding group of professionals,” said Richard Cherry, president of Global Optics.

Formed in 1971, Global Optics’ mission is to, “provide independent laboratories a means of sharing ideas and goals that lead to better service and product quality for eyecare professionals.” With the addition of Toledo Optical, the group now has 20 members.

|

| At the Global Optics national sales meeting are, left to right James Shrick of Essilor’s Independent Distribution Division (IDD), Tom Yancy and Rodney Yancy of Specialty Optical Services and Bob Colucci of Essilor’s IDD. |

|

| Tim Fortner from Transitions Optical presenting, “Telling the Best Story.” |

|

| Sales and marketing participate in a break-out training session. |

Global Holds Annual 2007 NSM—More than 60 optical lab owners and managers from across the U.S. gathered here from May 2 to 4, 2007 to attend the fifth annual national sales meeting for Global Optics, an organization of independent wholesale labs.

The two-day meeting consisted of training, workshops and special event designed for sales and marketing representatives.

“This sales meeting is a chance for our sales representatives to learn about the new marketing tools and products available to them from Global,” said

Geff Heidbrink, chairman of the Global Optics marketing committee. “In a competitive industry, the new tools released at this meeting will help separate independent Global member labs from their competitors.”

Global introduced three Global exclusive marketing initiatives designed to increase premium lens sales by helping to educate not only the ECP, but also the patient directly. These initiatives include the Jumpstart ECP training series, LenStock.com, an online source to order stock lenses and a new vendor neutral video designed to educate patients on the benefits of premium lens products. |

|