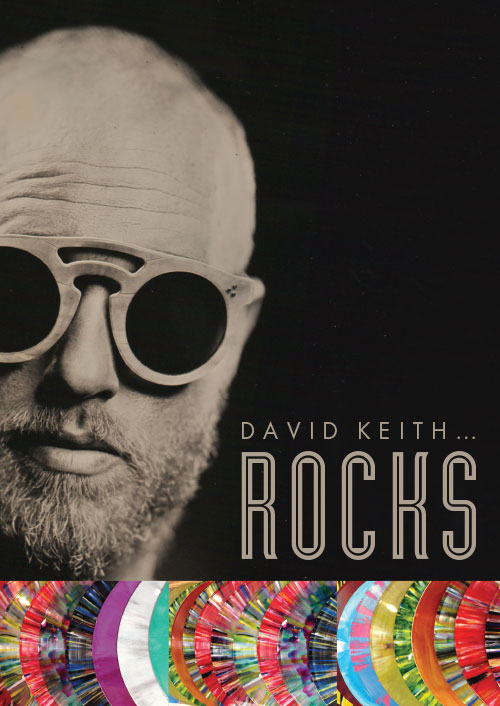

Portraits photographed by blackarttintype.com

As told to James J. Spina

Sometimes… you just need… to let… a story… tell itself.

Sure, you’ve read all kinds of told tales here in 20/20 and elsewhere about highly creative artists and designers and innovators, and you’ve been presented with that in anecdotal recaptures by an editor or a Q&A by a writer intent on bearing witness. But… this tale is best told by the person it entails. His name is David Keith. His eyewear is Spexwax. All I really want to say is… HE ROCKS:

Hello James. Thank you for taking the time to see us recently and hoping to see you at Expo. As per our conversation, here are the details about Spexwax eyewear...

Hello James. Thank you for taking the time to see us recently and hoping to see you at Expo. As per our conversation, here are the details about Spexwax eyewear...

My optical experience began in Sacramento, Calif. I was 21 and “fell” into this industry by pounding the pavement, filling out applications for all sorts of work in my local neighborhood.

I started out working for a privately-owned, independent optical shop (NO DOCTOR ON-SITE) called Individual Eyes in downtown Sacramento, about six blocks from the Capitol. In my interview, I explained that I really wanted to work there and I would do anything for a job… “I’ll clean your toilets with a toothbrush.” I guess my enthusiasm paid off because a few days later the phone rang with a job offer.

When I started work, Kurt the owner put me on an old Optical Dynamics casting machine to see what I could do. Obviously, I showed SOME aptitude. By the end of my almost three years at Individual Eyes, I was adjusting and selling frames. In that time, I had developed my skills to the point that I could cast lenses from a (CR-39/Poly) liquid monomer gel, surface the lenses and dispense them to the patient’s eyewear within an hour. “Make yourself invaluable, David,” my father used to tell me. “Because when you find something you love, it just won’t feel like work at all.”

After working in Sacramento at Individual Eyes, I moved to South Lake Tahoe where I continued to apprentice as an optical technician. I got my optician’s license in 2004 and moved to San Diego in 2006 for some warmer weather. I got a job within a week of moving to San Diego. I passed out my résumé to boutique eyeglass shops in and around downtown San Diego. I was hired the same week by Phil Harris, a third- generation optician with 45 years in the business and the owner of Eyes on Fifth. Phil has been my friend and optical mentor since the first day we met. After working for Phil for a couple of years, he just blurted out one day, “Hey Dave, what do you think about making eyeglasses out of old vinyl records?” He told me he thought of the idea 30 years ago, wrote it down and mailed it to himself. For me, it was like a lightbulb went off.

From that moment on, I couldn’t get the idea out of my head. With my experience and artistic bent, having worked as an optician for over several years in independent optical shops and aware of the trends in the optical industry, from blinged-out designer sunglasses to the return of antique eyewear, to using non-traditional materials like wood, horn and bone, I knew that Phil’s idea of eyewear made out of recycled vinyl was right up there with the top trends. I told Phil my thought on the idea, he wished me luck and that weekend I grabbed a scratched-up, unusable Lou Reed album and started crafting my first pair of 100 percent vinyl record eyeglasses... thus “Spexwax Eyewear” was born. Since founding Spexwax Eyewear, I have started accumulating the optical tools that any optician worth his salt (or hot air) needs to make eyeglasses. By saving my pennies and working on trade a lot(!), I now have a full-on optical shop to produce prescription and non-prescription lenses specially designed for Spexwax frames.

From that first experience, I realized I needed records—lots of them. As a music lover, it was important to me NOT to take perfectly good, playable albums and ruin them. Rather I wanted to take the hundreds of thousands of damaged vinyl albums out there in flea markets, people’s garages and donations and repurpose them into functional art you can WEAR.

Since 2008, I have gotten the word out that I can repurpose these records into wearable art. The response has been enthusiastic. I get the majority of my materials by using cast-off, imperfect or otherwise unusable records from record companies that still produce albums for current artists today.

The record companies understand the value of making something beautiful and functional out of damaged or discarded product that can’t be sold and would have to be destroyed. These days, a lot of people also donate to us rather than sending to the landfills.

From the time I started making frames out of cast-off vinyl records, I have constantly been innovating the process, frames and techniques to build “art wear,” not just eyewear. For a time, the entire Spexwax business was in my 250-square-foot living room. In order to innovate and assemble the frames, I often paid my friends with pizza and beer to help me laminate the frames.

My pizza and beer investment allowed me to instead invest my cash in tools and equipment to produce high-quality, ever-evolving frames. As I innovated, I used optical and not-so-optical tools to make each innovation better than the last.

The hardest part in producing a high-quality, handmade frame was fulfilling my vision of a classic Spexwax look. In designing, I knew I wanted a certain style but also top-notch quality. From the riveted hinges to the titanium nosepads, I looked for parts that were not only the dimensions I needed, but precision pieces of the puzzle to enhance that “Spexwax” style. I finally found what I needed: hinges from Italy, nosepads from Japan. It was like gathering the pieces of a puzzle; a puzzle that took two years of trial and error in teaching myself how to fabricate frames that were not only artistic, but also comfortable for the wearer.

After honing the process and with business picking up, I needed an extra pair of hands. I posted an ad on Craigslist: “Learn the art of making eyewear,” the subject line read. Along came Gary Bowers, a union carpenter who had made his way from Connecticut to San Diego. I put Gary to work sanding frames, but he has become way more than an extra pair of hands. In nearly two weeks, he became an artist of eyewear: laminating frames, sanding them to a smooth finish, riveting hinges by hand, running a lens edger and beveling the lenses to finish them off for mounting. Now Gary is doing design work, creating, innovating and enhancing the shapes of the Spexwax line. Over the last year, I have taught Gary how to make glasses, and Gary has taught me a lot about passion for your work and really being proud of whatever you’re making. He is invaluable to Spexwax.

Each frame takes about three weeks to hand-make from start to finish. After the frame is complete, Kei Masuda (Gary’s girlfriend), our very own Minister of Origami hand-makes album covers into functional and durable cases. My frames are handcrafted with love and are truly made from the vinyl of record albums. It is an important distinction because people who buy this ARTWEAR need to fully recognize what they are buying.

To sum things up, as an optician, it was important to build a brand that included the ability for anyone who needed corrective lenses to be able to fill their prescription through Spexwax. We specialize in custom-making glasses for those people who think outside the box. A person who craves having a designer make something for them that accentuates their individual style, jawline and facial features is our favorite clientele.

I made a personal business decision when I first started out, to not take any investments from suitors who want to mass-market Spexwax. I truly enjoy hand-making each and every frame, and I know it shows. Hopefully in the not too distant future, I can grow the business in size so Spexwax Eyewear will create new jobs for others interested in creating eyewear artwork.

My goal as an artist, designer and optician is to show the optical industry that instead of taking a great idea, outsourcing it to China and/or selling out to someone trying to sell to the masses... I can show some consumers that there still are a few craftsmen and artists of eyewear here in the USA who provide functional art you can wear on your face!

I should note specifically that one of my main sources for colored vinyl is Gotta Groove Records in Cleveland, Ohio. Most people recognize vinyl records to be black, but these guys specialize in producing records for today’s artists on amazing colored albums. I was doing an Internet search on colored vinyl a couple of years ago, looking for a record manufacturer that had throwaway, cast-off, fluff or imperfect records that they would sell me. After seeing my product, Vince, the owner of Gotta Groove was totally on board. He calls me when they have about 200 records to ship, which happens three or four times a year. So as you can see, we have lots of colors to choose from even though we are somewhat limited by what we receive from them.

Every Spexwax frame is handmade out of an unplayable vinyl record. We aren’t fooling anyone with what this material is. When you buy a pair of Spexwax, you must treat them like any frame using non-traditional materials, such as buffalo horn or wood. Remember, always on and off your face with two hands.

If they are not on your face they are IN THE CASE.

Intrigued? I certainly was. If you are too, here are details for getting in touch with David. Tel: (619) 581-2868; Website: spexwax.com; E-mail: [email protected]. Tell him 20/20 sent you.