By Jackie Micucci

Dennis Zelazowski was quite literally born into the optical industry. He comes from a family of optometrists that includes his father and grandfather. “Some of my earliest memories are of my grandfather in the basement where the lens lab was, grinding the lenses by hand on the hand stone and chipping away the lens with those little hand cutters,” he recalls.

Dennis Zelazowski was quite literally born into the optical industry. He comes from a family of optometrists that includes his father and grandfather. “Some of my earliest memories are of my grandfather in the basement where the lens lab was, grinding the lenses by hand on the hand stone and chipping away the lens with those little hand cutters,” he recalls.

His father opened a shop in Pittsburgh, Pa. in the ’80s where a 13-year-old Zelazowski would help out. “I didn’t start working there until ’92,” he says. “I was in the optical, in the back listening to the girls up front sell. I’m a little guy with little fingers and they’d hand frames to me and say, ‘Here, adjust these. So I’d do repairs. I was in the back and then I worked my way out front to do sales. I did that through my college years.”

After graduating, Zelazowski decided to go to the west coast where he worked for companies such as U.S. Vision as well as independent doctors. With business experience now under his belt, in 2001 he headed back to Pittsburgh to work in the family practice. At the time rimless was very popular, so he did a lot of custom shapes. Zelazowski was back in his favorite place, the lens lab, but found there were so many other facets of the business to handle. That’s when he got involved with practice management software.

“I thought, wow my email is getting really high-tech and user-friendly but my practice management software is really archaic and old,” he says. “I had been thinking about this since ’96/’97 and then we began to write the code in 2001. Basically it was web-based and it was custom so it allowed me to build things the way I wanted. It really automated the business. It freed me up to do other things like work with patients, work on selling and do some of the lens work.”

This only whetted Zelazowski’s appetite toward more innovation. He was approached by a frame vendor friend to design an eyewear concept. After the design was patented by the company, Zelazowski decided the next concept he created would be patented under his own name. This soon led him to invent the Chemistrie magnetic clip system.

“I wanted to sell a clip-on to everybody because it was a great feature to have,” Zelazowski says. “It was easier to sell than a second pair and it was a good value add-on. I began to push that really hard to everyone who was getting sun lenses. It was great because I could make that increase at the point of sale, but then it became a test case of everything that could go wrong with these products—the lens base curves mismatching, scratching lenses, big gaps between the lenses, lenses shrinking and falling out of the eyewire, eyewires always going out of adjustment, being stuck with one lens color, not being able to choose a designer frame, clunky, difficult to put on and scratching the frame. I said there’s got to be a better way to do this.”

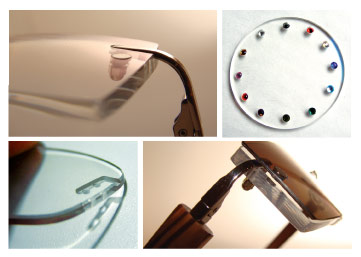

So he went back into the lens lab armed with his trusty hand drill. “I was using my little hand drill making a pair of Silhouettes one day and I thought I could just drill right into the lens,” he explains. “All lenses are drillable so I can make this for every lens. And because we’re making it after the prescription lenses are made or at the same time as the prescription lens, we can curvature match the lenses. By putting a curve match we get such a nice tight fit with the lenses. There’s no gap, there’s no rubbing, no scratching, there’s no interference between those layers. It’s fun. It’s user friendly. It’s really easy to use. It’s lightweight. It keeps the look and style of the glasses intact.”

Chemistrie started with 16 polarized colors, eight of which were mirrored and recently added gradient polarized lenses. “The technology started with polarized lenses and layering the lenses and now we’re moving into more advanced technology which is refractive layers,” notes Zelazowski. “Traditionally opticians and optometrists have been told for years to put as many features into that lens as you can. Put the edge polish, put the AR coating, put the photochromic, put the mid, the near, the far. Put all those properties and characteristics into one lens. The result is sort of a compromise and a very expensive lens.”

The

Chemistrie System addresses those compromises by mounting thin wafer layers onto the lens. “We’re now breaking the properties of the lens into different wafers and different layers,” explains Zelazowski. “So we have a patient who has a progressive in their glasses but their computer is up here and they have to do this [he stretches his neck like a turtle], which results in a lot of neck fatigue. If you put a plus 1.0 or a plus 1.50 over that progressive now everything’s raised. It’s much wider. Or for patients who have difficulty adjusting to a bifocal line, maybe they don’t like that line in their field-of-view or the progressive is difficult to adapt to, now they can have a single-vision lens in their frame and put on that progressive when they want it. By offering it into a layer it allows people to accommodate at their comfort level, it allows them to remove it for activities they may not want it for. It’s less expensive and bulky than a second pair of frames, which is really only sold at 10/15 percentage points of regular glasses.”

Chemistrie System addresses those compromises by mounting thin wafer layers onto the lens. “We’re now breaking the properties of the lens into different wafers and different layers,” explains Zelazowski. “So we have a patient who has a progressive in their glasses but their computer is up here and they have to do this [he stretches his neck like a turtle], which results in a lot of neck fatigue. If you put a plus 1.0 or a plus 1.50 over that progressive now everything’s raised. It’s much wider. Or for patients who have difficulty adjusting to a bifocal line, maybe they don’t like that line in their field-of-view or the progressive is difficult to adapt to, now they can have a single-vision lens in their frame and put on that progressive when they want it. By offering it into a layer it allows people to accommodate at their comfort level, it allows them to remove it for activities they may not want it for. It’s less expensive and bulky than a second pair of frames, which is really only sold at 10/15 percentage points of regular glasses.”

Zelazowski sees this as opening up a new dimension for ophthalmic lenses. Ophthalmic lenses in layers as opposed to all in one. “Not a lot of labs have jumped into this because it’s technically difficult so Chemistrie is in the process of sourcing the lenses and supplying the lenses with AR coating, with the base curve ready to edge just as we do with the sun lenses. It will be a turn key system that ECPs do not have to surface or coat. They can just throw it into the edger and add a reading layer or add a progressive layer.”

Chemistrie recently partnered with Santinelli. “We approached the labs and we said, Hey if you want to make this Chemistrie layering system it’s a great boom to your lab as far as productivity and profitability and creating a niche for yourself,” explains Zelazowski. “You have to buy this $50,000 edger. (The labs are pretty big so they can afford that) and then the labs have to buy the edgers. So pretty soon we’ve sold, 10, 20, 30 edgers. Gerard Santinelli says, ‘Dennis. You’re selling more edgers than my salesmen. How can we help you to sell more edgers?’” The result was the Click Mode software.

“I said we would love to work with you to create a software routine. So Santinelli built a hardware piece into the edger in terms of a diagram,” he says. “They built the different sizes available so when the operator brings up the shape on the screen it’s the binocular lay out, one to one size. When you hit the Chemistrie button it puts the magnets on. It streamlined it, made it consistent quality and production. That’s why we aligned with Santinelli because their equipment and their machinery behind it is the top of the line.”

However, Zelazowski is not one to rest on his laurels. While the Chemistrie Lens System has been a success, in true mad scientist mode he started to turn his attention to another optical innovation.

“About six months after I had gotten the patent file for the Chemistrie magnetic lenses I was thinking about doing a screwless hinge,” he says. “Everybody has their ball in socket or little type of screw-less hinge. I want to do a screw-less hinge. The little screws are the bane of the existence of the optician. I looked at the door hinge one day and it looked like little magnets kind of stacked up. I thought, why not do a magnetic hinge? So I took a pair of glasses apart and I put them on a grinder. I grinded off all the hinges and glued little magnets into the hinge. I was up late at night like a mad scientist and then I came back at six in the morning and I was anxious to try it. Lo and behold it worked.”

The hardest part for Zelazowski was finding a factory to source the magnets. It took him five years, but he found one. He shows off the prototype that he is wearing. “This is a maintenance-free product,” he says. “How many people fall asleep in their glasses or sit on their glasses. This will solve that issue.”

The first collection consists of rimless titanium. “Next we’re going to move into styles with fancy temples, then semi-rimless groove and zyls. But I wanted to start with the three-piece chassis because it’s the most technically difficult to do,” he notes.

Zelazowski’s enthusiasm is contagious. When you speak to him you can tell he truly enjoys what he does and understands the needs of opticians. “That’s the thinking behind Chemistrie products: It’s innovative, it’s new, it’s fun, it’s easier to use,” he says. “We really want to deliver the Os something we can stand behind and they can too. They can put their trust in us because we’ve done the homework to make sure what they’re getting is going to work… and it’s going to work well.” ■