Titanium Eyewear, More Than A Material's Reputation

By Mark Mattison-Shupnick, ABOM

Release Date: November 15, 2015

Expiration Date: December 15, 2016

Learning Objectives:

Upon completion of this course, the participant should be able to:

- Understand the basic material science behind how surfaces are kept clean.

- Understand the surface chemistry difference between coatings and the cleansers that are required to clean them.

- Hard coated and AR lenses have changed, learn how lens care is still a science and an ECP opportunity

- Learn how to present, discuss and sell through these new premium lens care products.

Faculty/Editorial Board:

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Course STWJH645-1.

Support:

This course is supported by an educational grant by SEIKO Eyewear.

Contemporary SEIKO Titanium chronograph watch |

Since the 1980’s, when watches were introduced in titanium, I’ve marveled at the way such crisp edges and shapes could be combined in a metal object with such a strong and lightweight design. While titanium technology in eyewear is now common, manufacturing invention and improvements have changed the looks, colors and combinations of the way that titanium frames are delivered. This product spotlight updates why titanium frames have become an expectation in every office and why the right titanium frames make a difference that consumer’s appreciate.

As we’ve learned, consumers are well informed and feature-focused. Consumers crave durable, lightweight frame and lens materials, are concerned about allergies to nickel and they want long-lasting, corrosion-resistant frames. That means that more than the word titanium will make a difference. It requires some homework.

| In a Nutshell Quality titanium frames are worth their extra cost. Patients purchase again and again because the overall value of comfort (wonderfully less than half the weight of other metal frames), flexural and dimensional strength (flexes when needed but always holds its shape), durability (corrosion and mishandling resistant) and hypoallergenic (resists bodily assault) makes them a first consideration. |

From a previous 20/20 Magazine article, “Frame material composition is the most common factor when it comes to what makes each style of eyewear unique in appeal. Material composition crosses the broad border of endless shape variations, increasingly countless brands and the ever-expanding possibilities of color and quality. Enlightened dispensers realize that a clear understanding of the variety of materials available might offer the key advantage to winning sell-through approval from patients.”

MATERIAL MATTERS

Titanium’s competitor in the optical market is stainless steel. Titanium is more costly than stainless steel, but with a specific gravity of 4.5 compared to 7.9 for stainless steel, titanium is as strong as steel but almost half as light. Although 60 percent heavier than aluminum, titanium is twice as strong, less brittle and extremely non-corrosive compared with aluminum and most other metals. Because of its unique molecular structure, titanium is the leader in metals that are hypoallergenic. Why are these attributes so important?

Repurchase Cycle

TITANIUM'S TALE |

From VisionWatch, an annual Vision Council study of >100,000 consumers, we can learn how often and generally why consumers purchase new frames. That’s one way to use the attributes of and substantiate the need for quality titanium frames.

For example, the 18-34 age group purchases a new frame every 2.0 years while 35-44, every 1.8 years, 45-54, 2.0 years and >55, 2.5 years. Age groups that repurchase sooner may be driven by trends and style changes while longer cycles are more durability concerned. That suggests that the words used, when selling to each age group also change. To appeal to each age group’s wants for eyewear, ensure that solutions to wants are communicated. Titanium frames can be “high style and have great dimensional strength” or “deliver terrific durability while being so light weight”. One can say, “Rarely need adjusting, rarely break, that's why their extra cost is such a good value”.

Bodily Assaults

Durability though has many definitions; for frames, it can also mean shape retention. Monel metal frames are easily bent out of shape over time with every day’s on and off. Or, changed into a piece of modern art after sleeping on them on the couch. Not so with quality titanium frames. Their flexibility yet stiffness of manufactured form keeps them in the shape in which they were made. That’s because the metal requires extreme press forces to form a parts shape. Therefore, it will take more than the weight of my mother-in-law’s best shot at meatloaf to bend these frames out of shape.

Your customer’s bodies also assault frames daily, almost invisibly. Look on the web and it’s easy to see comments by consumers about the two green lines left on the sides of their heads from their eyewear temples. For these folks, the friction of movement and their sweat attacks the temples inside surfaces before the temple cover begins and then seeps into the minute spaces between the temple cover and its core. The result is an attack of the metal’s finish. It appears as a green salt, a by-product of a reaction between acidic sweat and the copper and/or nickel temple component. Yechhh!

The patient returns to your office annoyed, thinking poor quality frames. They have gone online found others with the problem. They’ve learned that others have cleaned their eyewear with toothpaste or used a jeweler’s cloth to remove the green residue. But, that doesn’t fix the problem. The issue as we’ve learned, is that a number of individuals are allergic to the nickel or copper component in eyewear metals. Make these experiences a reason for customers to choose your office. Show them that you understand the issue and, as a solution, regularly offer quality, hypoallergenic titanium frames. Problem averted.

The word “hypoallergenic” resonates with consumers and describes a material’s attribute that means “inert” when worn on or inserted in the body. Pure Titanium frames are inert. As a result, consumers seek out those frame materials that continually demonstrate that they are hypoallergenic. Teach consumers about the extra value of adding hypoallergenic materials to their eyewear.

MY FATHER IS STRONGER THAN YOUR FATHER

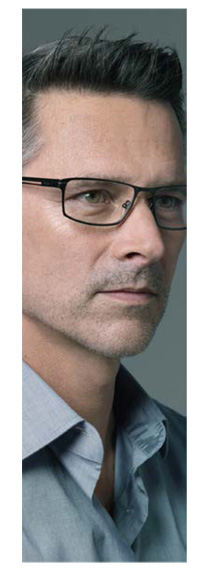

|

Half the weight and more strength is the appeal of titanium. Strength here also has a number of definitions that include strong, flexible, durable and resilient. After all, frames undergo extreme durability and flexibility testing during their life on a patient’s face.

But, it’s titanium’s strength that makes it so much appreciated by wearers. So strong in fact, that it is used for some of the best golf club drivers available.

To get them ready for those trials, the industry created a number of standard tests (ANSI, ISO) so that you can ensure that frames resist corrosion by human and household chemicals, like the effects of artificial sweat and saltwater. Other tests confirm a frame’s deformation and impact resistance. That testing allows you, the dispenser, to make claims that you can stand behind.

For example, ISO 12870, is an international eyewear standard that describes the fundamental requirements for unglazed spectacle frames designed for use with all prescription lenses. One test requires that frames be exposed to a chemical mixture that replicates perspiration, tests a frame’s components to assure that there is no spotting, color change or corrosion, surface degradation or separation.

Metal refiners and manufacturers describe the characteristics of the better grades of titanium used for eyewear and watches in words that we can use. Titanium is, “a perfect excellent combination of high strength, toughness, and ductility along with good weldability and fabricability”. That says it all.

Only Chink in the Armor

Titanium frames are easily flexed and formed for the fit wanted. But, for example, a hastily bent titanium temple or endpiece, at a single point, when using a metal plier can snap the titanium at the bend. That quick bending action can create a chink; a gap or crack in the metal. That can lead to the endpiece or temple breaking at that point. Bending ttanium endpieces and temples requires small crimp-like adjustments. That means that adjustments are a more natural shaping of the frame as needed without any compromise to the strength of the titanium.

|

If a frame breaks, titanium frames can be laser welded. To reduce any oxidation, that would discolor the frame, the parts are welded in an argon gas filled chamber, eliminating oxygen. The operator sits at an instrument that uses a microscope to focus on the parts to be welded within the chamber. This ensures both precision welding where needed, without exposure to oxygen. The temperature within the chamber is cool, but the spot at which the welds will be placed are hot. The precision produces little damage to the surrounding metal. There are laser welding repair shops around the country that specialize in titanium eyewear repair (and jewelry) should you need it. Most optical offices already have a titanium frame welding resource.

SIZE MATTERS

Fitting progressives? Of course you are and that means that the frames that are chosen really should have enough vertical size or lens area for the kind of progressive lens utility that today’s older consumer demands. Remember, most presbyopes have higher add powers today since the average presbyope is about 63 years old and wears a +2.25D to +2.50D add. They typically have a distance prescription also.

Delivering the best reading and mid-range functionality, demands enough lens vertically. Increased vertical size increases lens size and adds weight. To ensure comfort and best manage an increase in lens weight, use lighter lens materials, especially titanium frames. Frames made of titanium are about half the weight of comparable metal frames and therefore, manage size better.

WHAT SHOULD YOU SAY?

Now that titanium is understood, convert that knowledge into the words that you would use with the patient turned customer. After all, the technical words we use to understand frames and lenses should be converted into a script that we can use. I took these words from a SEIKO features and advantages brochure since it covers the variety of benefits that patient’s value.

“Quality titanium frames cost more.” Although an abundant metal, titanium is difficult to mine and purify. Special soldering is required in oxygen-free environments at temperatures over 900°F. Special detailing and shapes require heavy machine presses specifically designed for titanium processing. That adds to their higher up front cost. However, the benefits that they deliver make them one of the best values when choosing a frame.

They are, “…so lightweight; because titanium weighs half the weight of other metals”, even when comparing stainless steel used to make beautiful frames. “Less weight makes them more comfortable” so they are easy to wear and they complement today’s lighter lens materials. “Titanium makes frames that are more durable” and therefore a better value; their high tensile strength creates a more durable frame that “stays in shape longer”.

“Titanium frames are 20X more corrosion resistant” than even the finest quality Monel or nickel/silver alloys. Because titanium, when exposed to oxygen, creates a film layer of ceramic like oxide, it lends itself to applications where corrosion resistance is a concern. Should the metal get scratched, as long as it is exposed to oxygen, the scratch will re-heal itself with the oxide film. This allows our office to confidently dispense frames that maintain luster and beauty for a longer period of time, regardless of climate or skin chemistry.

|

Because 90-100% pure titanium frames are Nickel free, health problems caused by nickel absorption make titanium frames a smart choice for our patients concerned about frame chemistry problems.

“Men like titanium for the technical aspect” and “women like it because it’s lightweight and doesn’t leave any marks on the face.”

ADJUSTING TITANIUM FRAMES

What about adjusting a titanium frame? It happens but infrequently. That’s because they typically require less adjustment because of their tensile strength. When needed, follow the same steps as other metals.

Like other metals, we would start with checking whether the front is propellered. In flat sheet-like titanium fronts (Fig 1), it would take extreme force to get them propellered. As a result propellering is rare. That ensures that lenses are kept in their right positions for best vision.

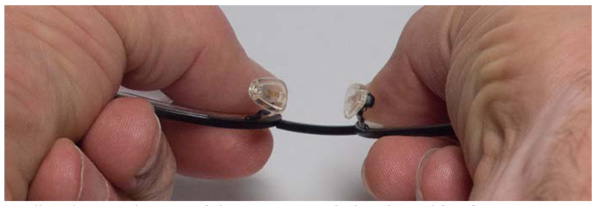

If it does happen, it's a result of a narrow or thin bridge. Grasp both eyewires as shown in Fig 2, with small twists, straighten the front and remove the propeller.

Fig 2. If propellered, grasp the tops of the eyewires with thumbs and forefingers, twist to straighten |

Changing pantoscopic angle requires the right pliers. Use pliers whose metal jaws are nylon covered. That ensures that the plier jaw will not mar the frame’s surface or finish.

Fig 3. To adjust pantoscopic angle, I've grasped this SEIKO frame firmly with the left hand (I'm right handed) and with a parallel covered jaw plier, rotate the angle of the endpiece to the desired tilt. By rotating the endpiece, the hinge and barrels are not stressed or broken. |

Temple and endpiece bends are dependent on the temple dimensions. For example, the frame in Fig 1, does not allow significant pantoscopic adjustments. Titanium frames with a thinner attachment point for the endpiece can be adjusted using a parallel jaw, double covered plier (Fig 3) while bracing the front.

Temple tension, an important fitting factor in eyewear, is the result of the tension from the endpiece and a near parallel alignment of temples. The stiff yet flexible nature of titanium temples holds this alignment longer than most other frame materials.

Eventually, over flexing of the temple can make the endpieces flare which will need adjustment to renew them to their original shape. Over flexing can also be reduced by temple design.

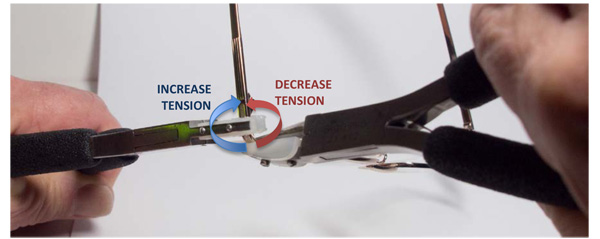

For example, in the SEIKO Flex Action styles (Fig 4a), the folded twists ensure easy flex yet the volume of metal maintains shape and position. The other way to ensure a snug fit of the temples is to adjust the endpiece to reduce or expand the angle of the temples to the frame front (Fig 4b). Last, the use of beta-titanium adds a springiness and flexibility that’s remains as a temple property for the life of the eyewear.

Fig 4a SEIKO Flex Action, folded twists for temple tension and flexibility |

Fig 4b grasp the endpiece with a double covered parallel jaw plier (left hand) and using a post/flat covered jaw plier (right hand), rotate the plier in the left hand to increase or decrease tension by reducing or opening the curve of the endpiece. |

Temple ends are thinned to allow the easy bend that’s required at the top of the ear to keep frames from sliding down the nose (bend occurs too far back) or for temple ends to work their way up the ear (bend occurs too far forward). The bend needs to be moved to the position, at the top of the ear attachment, required along the temple cover. Adjustments require a small amount of heat. A hot air frame warmer is recommended since a salt or bead bath heater tends to pock mark plastics. Use the forefingers and thumbs of each hand making the bend to produce a 45-degree bend (Fig 5).

Fig 5 Add some heat, then use your thumb or forefinger below the position needed for the bend |

WAS A TIME WHEN LITTLE COLOR

Over the last few years, the technology that colors titanium frames has improved greatly. Fig 5 is a good example of color opportunities; here red and black are combined. Creating contrast is a good method of selling eyewear in addition to the frame’s actual style.

Use of color in a woman's frame collection, frames, SEIKO Titanium  Use of color in a man's frame collection, frames, SEIKO Titanium |

As a result, while many titanium eyeglass frames have varying shades of grey and black, there’s no reason to limit the collections purchased. As we know, the consumer is wearing many more colored frames as part of their individual style.

THE RIGHT BRANDS IMPROVE YOUR OPTICAL BRAND

KNOW 5 PATIENT BENEFITS |

The brands carried in your office are much more than just their name or a logo. A brand identifies the products and/or services of one seller or practitioner, and clearly differentiates them in a meaningful way from the competition. A brand is a set of differentiating promises, which link a business or practice to its customers or patients. It is a set of expectations and associations that are developed as a result of experience; the enduring impression and sum total of every experience and interaction that a customer or patient has with the business or practice (from the CE, The Basics of Branding, Oct ’07).

The name ‘titanium’ is a brand in and of itself as you’ve learned. Selecting a particular company’s titanium adds another set of differentiating promises. After all, the company’s brand name should evoke trust and quality. Therefore, choosing the right company brand can enhance your own personal and professional brand identity. Like other brands you use, Seiko has a reputation that means highly crafted and reliable.

For example, 100% titanium frames use the identity of titanium to provide all the high-end benefits of titanium metals in eyewear. Then using the frame’s brand name combines a high-end material with a brand name that has its own set of differentiating promises. This attaches both to your practice.

For example, if you were to use the statement, “Seiko Titanium frames will almost always stay in adjustment”. That improves the impression of value in two ways; it uses the reputation of titanium for strength and the durability to improve your reputation for understanding the value that patients appreciate. The frame brand carried further shows that your choice is one of known brands that engender trust. By doing so, a discussion about peace of mind, for both your patient and for you, makes sense. It’s good to say that, “We can have peace of mind knowing that we’ve chosen the right brand and material to meet your wants for a long lasting, durable and lightweight frame.

THREE KEYS TO HOW TITANIUM CAN STRENGTHEN YOUR BRAND

1. Clearly and properly position your brand by clearly showing and discussing titanium eyewear. Remember, frame materials with strong identities and brands occupy a clear, distinct place in patients’ minds. That will improve your own brand identity and that of your office. Be sure that you identify and communicate how these frames are different from the competition in easily recognizable and meaningful ways.

2. Deliver the frame benefits that your patients truly want: Keep top-of-mind, the benefits that targeted patient’s desire. Patients choose one practice over another because of both tangible and intangible factors that create an appealing whole. Quality titanium frames deliver a variety of durable and hypoallergenic promises that patients appreciate.

3. Ensure that everyone in your organization delivers on the promise of the materials and brands carried: That means that everyone in the office should use the details of this course to deliver the same message about titanium and the quality brands carried. To deliver continuity of message there needs to be understanding and buy-in among all employees, at all levels, in all positions. Each employee must understand why titanium is used to make better eyewear and what the company brand stands for. Design the optimal patient experience so that everyone knows the gold standard for frame strength, durability and what that value is worth.

KNOW 5 PATIENT BENEFITS

- “Lightweight Titanium construction results in an extremely comfortable fit, which means less visits for adjustments.”

- “Titanium material is so durable you will save money in the long run.”

- “Titanium is non-corrosive, so you will appreciate frames that last and not discolor.”

- “Seiko Titanium Eyewear is completely nickel-free; therefore you can eliminate worries of any kind of allergic reaction.”

- “Seiko Titanium Eyewear is lightweight and durable, great for any active lifestyle.”

DISPENSING TIPS

As consumers, we would prefer to spend less, receive greater value, to pay as little as necessary for what we “need” and be completely happy with our purchase – why? That’s because we understand value. We’re not talking about cheap, but rather the reason that we spend. We will pay as much as necessary to get what we “want.”

It’s like buying a car, the sales person suggests the top of the line and provides a test drive. Then it’s an opportunity to remove some items not wanted. However, by the time you make a purchase you will probably have spent a little over your original budget because you’ve accepted a variety of luxuries that you’ve decided you wanted. In the dispensary, it’s the same. Have the patient test drive titanium vs. another metal frame. Then describe the benefits received even though it’s perhaps higher cost. This can translate into a titanium frame choice even with progressive lenses, anti-reflective coating etc. To do this well, determine the customer’s wants and sell them on the fact that they’re attainable. Who benefits? - The patient!

To be a “fabulous seller”, it’s essential to know all the features and benefits of titanium. This makes you the expert! Today’s consumers are more educated than ever; therefore you must know your product inside and out. You must be able to compare a $129 frame to a $250 frame by saying more than it is branded product. When you assume the role as expert, you become the expert about the value of the material, the solders, joinery, mixture of materials and its brand. This information sets you apart from the competition and solidifies a customer’s confidence. This is a must at the high-end level.

Price is what you pay, cost is what you receive and that is paid out over the product’s lifetime. When a customer says “the price is too high” or “this is too expensive” they are usually comparing this to a prior experience or what they think is a comparable product. After all, in the patient’s mind, a frame is a frame. You must ask the customer two questions: First, “Compared to what frame?” and, next “What is too expensive?” Once you have an understanding of the amount of ground you have to cover, you will most likely find that the lower priced product meets all the “needs, but few of the “wants.” This is where the two concepts come together: The product must meet all their wants. If you do, both you and the customer are winners. For frame purchases you must ask enough questions and at the same time be frame material and construction knowledgeable.

CONCLUSION

Titanium in many ways sells itself until it becomes a price discussion. To be successful, know the valuable property benefits of titanium that translate to the durability and long lasting comfort, lightness, strength and adjustment that titanium deliver. Be sure that every patient understands the choices possible so that titanium maintains its correct position in the arsenal of frame materials that deliver every patient’s wants.