Another Dimension of Prescription Polarized Sunglass Comfort, Thinness, Ahhhh

By Mark Mattison-Shupnick, ABOM

Release Date: November 15, 2015

Expiration Date: December 15, 2016

Learning Objectives:

Upon completion of this course, the participant should be able to:

- Understand the contributors to the comfort of polarized sunlenses (eliminates blinding glare, reduces scatter or Rayleigh's Effect, film position makes for thinner and lighter lenses, looks better so more comfortable when wearing Ahhhh!).

- Know how SEIKO PolarThin improves thinness and comfort for polarized lenses

- Learn the best ways to merchandise and promote more comfortable sunglasses - thinner and lighter polarized sunwear.

Course Description:

Ask an ECP what makes for a comfortable sunglass and I bet you hear a variety of answers. Polarized lenses, frame coverage, frame fit, high index if needed and the right lens color probably tops the list. But frame comfort is the result of frame size with lenses and its fit, so improving lens comfort benefits from thinner lenses. Polarized high index thinness is not just a function of the index but also the placement of the polarizing film. The closer the film is to the front surface, the thinner the lens center for minus lenses and the thinner the lens edge can be for plus. The result is a lens whose polarizing affect on vision comfort is enhanced by a thinness and weight improvement. This course is a product spotlight on the SEIKO PolarThin high index lens blank whose polarizing film is placed ~0.4mm from the lens' front surface.

Faculty/Editorial Board:

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Course SWJH516

Support:

This course is supported by an educational grant by SEIKO Eyewear.

What makes for comfortable prescription sunglasses? Close your eyes and think of a variety of answers before you read any further. OK, got ‘em? Then ask your ECP colleagues what makes for a comfortable sunglass, I bet you hear a variety of answers. Are they the same ones you thought of?

Polarized lenses, excellent frame coverage, the right frame fit, thinner lighter lenses if needed and the right lens color probably tops my list. But, frame comfort is the result of frame size with lenses. And, that makes fit critical considering that most sunwear is typically larger than everyday glasses. In prescriptions, larger frames produce thicker lenses and more weight. Therefore, higher index materials are of benefit. Agree?

When ordering polarized lenses, some lens materials suffer from polarizing film placement that is farther from the front surface than others. For example, when talking to lab people they say that SEIKO 1.67 allows 1.3mm minimum center thickness on PolarThin polarized. Other 1.67's require from 1.6mm to 2.0mm minimum centers, poly allows centers from 1.0 to 1.7 and CR39 is pretty consistent at 1.8mm (some labs do 1.5mm). The variation is a function of the manufacturer’s positioning of the film from the lens’ front surface. Farther film placement results in thicker prescription lenses than they would be if they were produced as non-polarized lenses.

Improving lens comfort therefore, benefits from a list of attributes, which you control. What are the details of those attributes to produce the really comfortable sunglasses that make patients return again and again, “…no one else can get it as right as you can!”

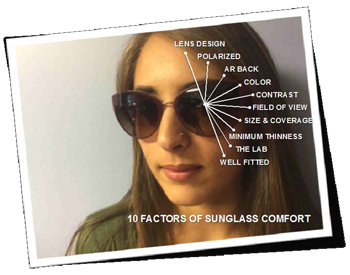

10 FACTORS OF SUNGLASS COMFORT

The comfortable vision of polarized sunglasses is often described, “like putting on an old pair

of jeans”. With the assumption that the prescription is correct, let’s divide this discussion of

factors into two parts, Vision Clarity and, Form plus Fit.

The comfortable vision of polarized sunglasses is often described, “like putting on an old pair

of jeans”. With the assumption that the prescription is correct, let’s divide this discussion of

factors into two parts, Vision Clarity and, Form plus Fit.

VISION CLARITY

Great vision requires excellent lens clarity. Lens design (1) manages prescription clarity at lens center but more importantly, edge to edge. You’re familiar with the free-form opportunities of changing a lens design from ‘spherical’ to ‘atoric’ to ‘optimized’ to ‘customized’ lenses in single vision, multifocal and progressive lenses. In each case, the improvement results in a wider, clearer field of view. That’s because the periphery of the lens is better tuned to the wearer’s prescription and the way that the glasses fit.

Spherical design lenses often called best form or in stock lenses is ‘out-of-the-envelope’; one size fits all, design.

Everyone with the same prescription gets the same spherical front and back lens curves. Free-form technology and your free-form laboratory allows us to improve that with an atoric back surface that adds differing asphericity to each of the principle meridians to improve peripheral vision. Consider this for all the flat top wearers with a 1.00D cylinder or greater.

Next, increase the Field of Clear View (2) by optimizing the lens back, edge to edge, using average lens fitting values or customize the back using the actual position of wear measurements for PD, height, vertex, tilt and wrap angle. Finally, personalize progressives so that their zone sizes better match the patient’s vision and lifestyle needs (available either with average or position of wear measurements). Personalization also allows customizing corridor length and reading inset. While each can add more cost for the wearer, the benefits and improvement in comfort typically outweigh the cost. The decision about which is best is the ECPs considered opinion about the wearer, their prescription and the demands that the wearer places on their vision. For example, -0.25-0.25 x 90, Add +1.75D warrants a different solution than a +0.25-3.75 x 95, Add +2.25D, especially if one drives for a living; the other is a programmer for a software company. Know how to teach each kind of patient the differences.

Make virtually all prescription sunglasses Polarized (3). Why? Three reasons – polarized

lenses better manage glare, use color more effectively and improve contrast. Polarized

sunglasses manage glare in two ways. They are the only sunwear that can eliminate blinding

glare, those intense reflections off a wet pavement or car hood that makes it impossible to

see during critical activities like driving, cycling or when on the snow or water. However, the

everyday comfort of polarized lenses is because polarization reduces the scattering of

sunlight in the atmosphere (Rayleigh’s Effect). The scatter diffuses the sun’s shorter

wavelengths (blue). While that’s the reason for the sky’s blue color and the yellow tone of

the sun itself, blue light is slightly polarized and

scattered 6x more than red. Wear polarized

sunglasses and most of the scatter disappears.

Make virtually all prescription sunglasses Polarized (3). Why? Three reasons – polarized

lenses better manage glare, use color more effectively and improve contrast. Polarized

sunglasses manage glare in two ways. They are the only sunwear that can eliminate blinding

glare, those intense reflections off a wet pavement or car hood that makes it impossible to

see during critical activities like driving, cycling or when on the snow or water. However, the

everyday comfort of polarized lenses is because polarization reduces the scattering of

sunlight in the atmosphere (Rayleigh’s Effect). The scatter diffuses the sun’s shorter

wavelengths (blue). While that’s the reason for the sky’s blue color and the yellow tone of

the sun itself, blue light is slightly polarized and

scattered 6x more than red. Wear polarized

sunglasses and most of the scatter disappears.

Next, pick a lens Color (4) that can help to improve the way that each patient see’s their world. Polarized sunlenses in true greys evenly reduce glare and maintain colors as they are in nature, no surprises there. For many patients, that is their preference. However, browns and greens improve contrast by further reducing blue scatter. Increased Contrast (5) improves the visibility of the edges of the objects seen. Make edges crisper and it can improve a patient’s 3D sense of the world around them. That can help with recognition. For some, perhaps there’s a mobility improvement i.e., the position in which objects are seen in relation to where the wearer is and where they need to go. In my view, comfort in eyewear is also a function of removing insecurities that a person has when using a pair of glasses. If glasses are poorly purchased, their optics can get in the way.

Polarization efficiency measures how well the lens eliminates reflected polarized light. The lighter the lens, typically the less efficient so darker polarized sunglasses are better in their effectiveness at eliminating those intense reflections called blinding glare. Contact your lab supplier for efficiency values.

QUICK PHYSICS OF POLARIZED LENSES

Molecules in a polarizing filter are long in one direction (horizontal) and short in the perpendicular direction (vertical). Electrons can freely oscillate along the length of the molecule, absorbing or reflecting the light energy, while they are unable to oscillate very far along the short direction. The "E-field" arrows in the Figure show the direction of polarization. The small spheres labeled "e-" represent electrons. Note in the Figure how the horizontally polarized wave (top) emerges) from its electron interaction with its amplitude reduced, while the vertically oscillating wave (bottom) comes through with undiminished amplitude. Image Source: voer.edu.vn.

POLARIZED LENSES REDUCE GLARE

Eliminates Blinding Glare which is reflected light, intensified 10-100x that hides objects that you might need to see, The result is a slightly darker image but with better contrast. They Reduce Atmospheric Scatter (Rayleigh’s Effect). The result is improved vision comfort, reduced haze and improved reaction time.

Lastly, polarized sunglass comfort depends on the axis position of the polarizing film in the lens. As much as 5 degrees off (ophthalmic polarizers are placed at 180 degrees) and a patient will notice a ‘shimmering’ of reflections or might experience some discomfort. Therefore, check the axes of single vision or free-form progressive polarized sunglasses received using another polarized lens held 90 degrees showing ‘extinction’ (blocks all light). In traditional progressives or multifocals, if the engravings or segment is horizontal, at 180 degrees, the polarizing film is also typically at 180 because of the manufacturers’ quality programs. .

A must for sunglass clarity is 6, an Anti-Reflective Back Lens Surface (AR). An AR back reduces

or eliminates the magnified back surface reflections (magnified when reflected by a concave

surface) that are so easily seen on a dark lens. Those reflections are always there and get in

the way because they are so much more visible because of the dark lens. Order back surface

AR to eliminate back lens surface reflections and improve comfort.

A must for sunglass clarity is 6, an Anti-Reflective Back Lens Surface (AR). An AR back reduces

or eliminates the magnified back surface reflections (magnified when reflected by a concave

surface) that are so easily seen on a dark lens. Those reflections are always there and get in

the way because they are so much more visible because of the dark lens. Order back surface

AR to eliminate back lens surface reflections and improve comfort.

Sunlens clarity is also a function of The Laboratory Chosen (7) to manufacture the prescription. The quality of the lens’ surface depends on the lab’s attention from surfacing and polishing through all the coatings. Lab finishing produces lenses properly centered, glazed and bench aligned. The correct application of quality assurance in the lab produces clear lenses for patients. Today’s modern lens laboratories manage sophisticated engineering, free-form technologies and consistent calibration through all the facets of the lab from ordering to shipping. Therefore, as important as design and lens choice, the fabricating lab adds another dimension to patient comfort.

FORM AND FIT

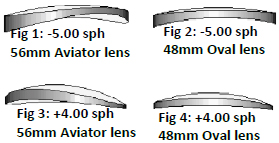

The Size (8) of sunglasses significantly affects comfort and Fit (9). Since sunwear is an

opportunity for big and is, in fact, actually delivers the fashion appeal and protection of

sunwear. However, it can negatively affect

comfort. For example, a -5.00 sphere lens,

56x42mm Aviator shaped polycarbonate sunlens,

edged for a 63 PD is 56% thicker and twice the

weight of a comparable 48x32mm Oval polycarbonate lens that might be the patient’s

everyday clear lenses. That’s the consideration and counseling that makes the opportunity

for higher index, thinner lenses, a discussion at the dispensing table. The same comparison

of a +4.00 sphere Aviator sunlens to the smaller

Oval clear everyday lenses shows that they are

49% thicker at the center and also twice the

weight (see Table 1).

The Size (8) of sunglasses significantly affects comfort and Fit (9). Since sunwear is an

opportunity for big and is, in fact, actually delivers the fashion appeal and protection of

sunwear. However, it can negatively affect

comfort. For example, a -5.00 sphere lens,

56x42mm Aviator shaped polycarbonate sunlens,

edged for a 63 PD is 56% thicker and twice the

weight of a comparable 48x32mm Oval polycarbonate lens that might be the patient’s

everyday clear lenses. That’s the consideration and counseling that makes the opportunity

for higher index, thinner lenses, a discussion at the dispensing table. The same comparison

of a +4.00 sphere Aviator sunlens to the smaller

Oval clear everyday lenses shows that they are

49% thicker at the center and also twice the

weight (see Table 1).

Now consider two additional things that affect thinness and lightness. First, the higher the index of the material, the more it improves edge or center thinness. Next, minimum lens thinness at the center or edge is also a function of the polarizing film placement. As a result, minimum thinness is dependent on film location.

Minimum Thinness (10)

Higher index and minimum center thinness because of polarizing film placement affects final

lens thickness i.e., the farther the film from the front surface the thicker the final lens. In the

following examples, using a variety of materials, the SEIKO 1.67 PolarThin allows 1.3mm

minimum center thickness because the film is placed 0.4mm from the lens’ front surface. If

we compare that to other lens materials we see that placing film at 0.4mm and thinner

resulting centers makes for lenses that provide the most savings for thinness and lightness

(about 25%). Table 2 lists the calculated thinness and weight reductions for -5 and +4 lenses,

respectively for a variety of materials and minimum thinness’s.

Higher index and minimum center thinness because of polarizing film placement affects final

lens thickness i.e., the farther the film from the front surface the thicker the final lens. In the

following examples, using a variety of materials, the SEIKO 1.67 PolarThin allows 1.3mm

minimum center thickness because the film is placed 0.4mm from the lens’ front surface. If

we compare that to other lens materials we see that placing film at 0.4mm and thinner

resulting centers makes for lenses that provide the most savings for thinness and lightness

(about 25%). Table 2 lists the calculated thinness and weight reductions for -5 and +4 lenses,

respectively for a variety of materials and minimum thinness’s.

A survey of labs suggests that other 1.67's require from 1.6mm to 2.0mm minimum centers because each of the manufacturers placement of polarizing film. Polycarbonate allows centers from 1.0 to 1.7 because some polarizing films on polycarbonate semi-finished are effectively on the lens’ front surface, covered by a hard coat, others below a polycarbonate Plano cover. CR39 is pretty consistent at 1.8mm minimum centers with some labs producing centers of 1.5mm. Again, the variation is a function of the manufacturer’s positioning of the film from the lens’ front surface. Farther film placement results in thicker prescription lenses than they would be if they were produced as non-polarized lenses.

In plus lenses, the edge thinness determines the lens’ center. That also changes depending on the frame style i.e., rimless and semi-rimless requiring a lens groove often produces a minimum edge thinness that is thicker than the same lens size and shape for a metal or acetate frame. Frame shape, size, decentration and the axis of the effective diameter also are critical to calculate the minimum edge thickness for plus lenses. As a result, understanding the minimum edge thinness’s possible, from your lab, for the variety of frame styles ordered is an advantage when setting patient expectations. Thinness can vary.

Fig. 5 illustrates a -5.00 lens produced from a semi-finished blank and the effects of film placement. It shows that thin center grinding works for the top example (the red dashed line). In the middle example, where the film is farther from the lens’ front, the center of the polarizing film would have been ground through. This lens blank and film placement would require a thicker centered lens to produce the same prescription (the bottom example). In this lens, both the center and edge results would be thicker.

Fig. 6 illustrates a +4.00 lens and the effects of film placement. It shows that thin edge grinding works for the top example because of the close film placement. The middle example would cause the edge to have ground through the polarizing film reducing the available diameter of the fully polarized lens. For this lens blank, to make this plus lens work, a thicker lens is required to match the edge thickness at full diameter (the bottom example). Both center and edge thickness is increased. As a result, film placement is very important to the final look and feel of lenses.

Size and Coverage (8) are inter-related. Look at this cyclist’s glasses,

and then look again at the image of the young woman at the beginning

of the course. Size and coverage is a key factor in comfort and they are

different. Comfort therefore has more than one meaning and coverage

describes how the frame and lenses deliver protection (glare and UV)

while they make the long, wearing times outdoors, a pleasure. We

know how to manage and consider size. Coverage ensures that the eye and its adnexa (the skin surrounding the eye) are protected. Consider ‘light leak’ at the frame

top, around the nose and at the sides. Good coverage reduces glare and potential problems

with UV exposure from all around the sunglasses. The cyclist is wearing lenses that fit close

to the cheeks; wrap around the sides of the face and fit close to the brows. Large is not

always the best. Don’t be afraid to point out these features or deficiencies of fit with the

patient, they’ll appreciate the good counsel.

Size and Coverage (8) are inter-related. Look at this cyclist’s glasses,

and then look again at the image of the young woman at the beginning

of the course. Size and coverage is a key factor in comfort and they are

different. Comfort therefore has more than one meaning and coverage

describes how the frame and lenses deliver protection (glare and UV)

while they make the long, wearing times outdoors, a pleasure. We

know how to manage and consider size. Coverage ensures that the eye and its adnexa (the skin surrounding the eye) are protected. Consider ‘light leak’ at the frame

top, around the nose and at the sides. Good coverage reduces glare and potential problems

with UV exposure from all around the sunglasses. The cyclist is wearing lenses that fit close

to the cheeks; wrap around the sides of the face and fit close to the brows. Large is not

always the best. Don’t be afraid to point out these features or deficiencies of fit with the

patient, they’ll appreciate the good counsel.

Last, the correct bend at the top of the ear ensures that the sunglasses don’t slip – large frames can do that. Also, a temple bend that occurs behind the crest of the top of the ear allows the frame to slip down the nose, if in front of the crest of the top of the ear, causes the frame bottom to tilt towards the cheeks and let’s too much light in at the brow line. As Goldilocks said, “A well fitted frame is, just right”.

THE STATS

The stats? We should feel that we want to change the numbers. That means more polarized prescription sunglasses.

It is estimated that almost 85% of consumers own a pair of sunglasses, average price $39 (VisionWatch, Vision Council). That means most are Plano, a small portion prescription. But, in the past when you ask the consumer what kind of sunglasses they wear, most will say,

“Polarized”. Based on actual sales estimates and average sell prices, that’s not true. In Plano sunglasses, the consumer knows that polarized sunwear is better. ECPs typically describe prescription polarized as the best sunglass. Yet, prescription sunwear fares much worse, with sales annually of between 10 and 15% of overall Rx sales and only about half of that is polarized. What do we need to know about polarized lenses and how can we capture this amazing opportunity that once the customer tries ophthalmic quality polarized, never goes back? What is the opportunity? What should you do?

SELLING POLARIZED SUNGLASSES

When patients are opposite you in the office, ask, “Bothered by those really bright reflections off the roadway early in the morning?” Perhaps you might say, “The most comfortable prescription sunglasses are the latest in polarized lenses, thin, light, visually like an old pair of jeans.”

Say, “Have you thought about the ultimate and affordable sunglass luxury when driving or outside in the sun during the day… a pair of polarized prescription sunglasses?” Or, “The best way to use your flex dollars or as a present to yourself is a pair of prescription polarized sunglasses.” The reality of selling more sunwear is making is a requirement for you and for everyone in the office to discuss the need for better sunglasses. After all, while the average selling price of a pair of Plano sunglasses is $39, optical offices and sunglass specialty stores attract and sell about 10% and 12% of the sunwear each sold annually. That says that the consumer is looking and will purchase better sunglasses. That means that a more knowledgeable person in the office can teach and demonstrate the advantages and benefits of quality-polarized sunwear.

OTHER THINGS TO KNOW

The better quality polarized sunglasses work with and sometimes against the way that the customer will wear them. Therefore, know what customers can be taught to expect with their new sunglasses.

LCD screens (smartphones, tablets, gas pump screens, car dashboard instruments, etc.) are polarized usually at about 45 degrees so when viewed through a quality, highly efficient polarized lens can be harder to see or completely disappear. That’s normal. Just teach customers to tilt their device or head 45 degrees to see the phone clearly. BTW, tilting the head in the opposite 45 degrees will make the screen invisible (called extinction in optical terms) so tilting the device or head in the correct direction is important.

Stress patterns of tempered car windows, that’s normal since a polarized lens will highlight the pattern, a result of tempering, that’s invisible to the wearer without polarizing glasses. I have found just a few customers over the thousands of polarized sunglasses sold that dislike the visibility of the pattern so much that I have changed their polarized lenses to tinted lenses. It’s a very few but you should be aware of it.

Recreational pilots and boaters have LCD gauges, that may not be easily visible. Yet, polarized sunglasses for the water is the norm so teaching a ‘tilt the head’ makes the difference. Explain that in detail.

Commercial airlines do not allow polarized sunwear, the wind screens are already polarized.

Be an authority on everything polarized and patients will recognize the value of your opinions.

TELL THE “AHHHH, LOVE THESE SUNGLASSES” STORY

As we described, everyone in the office, from reception, to technicians to doctor to optician teach the value and benefits of the comfort of quality polarized prescription sunwear. Get everyone in the office a pair of polarized sunglasses. Be sure to be able to tell the story from a personal point of view. Online, use facts from this CE course on Facebook, your website and as tweets. Work with your suppliers for materials and consumer point of purchase items that help start the conversation. In fact, those brochures provide really good language about the product that you can use.

POLARIZE YOUR OFFICE, TRACK YOUR PROGRESS

Count and record the polarized sunglasses sold, Plano and prescription. Then set goals for each day/week. Record and chart the progress monthly. At one of the weekly staff meetings each month, include a 15-minute discussion on polarized lens sales. Review progress, educate on areas that need additional discussion and revise your goals if needed.

NEXT STEPS

Humans have been protecting themselves from the bright sunlight for centuries. However, simply reducing light entering the eye using tinted lenses or by other means doesn’t eliminate blinding glare—it’s still the kind that reflects off many surfaces and scatters in the sky that makes us the most uncomfortable. Only polarized lenses reduce the sun’s scatter and bright glare and eliminates blinding glare. Enhance those basic comfort producing attributes for prescription wearers with the thinnest and lightest lens options for the best technical portfolio that only your office can provide.