Eyewear Design And Development

Looking beyond logos and markings

By Mike Hundert and Nicolas Roseillier

Release Date: October, 2012

Expiration Date: September 3, 2017

Learning Objectives:,

Upon completion of this program, the participant should be able to:

- Understand today's eyewear manufacturing dynamics, from country of origin to methods and materials.

- Better understand how to evaluate the eyewear purchased for your office.

- Learn how to best choose and describe quality eyewear for every patient.

Faculty/Editorial Board:

Mike Hundert is chief executive officer and chief creative officer of REM Eyewear. A journalist by education, a sports broadcaster and director of world pro skiing before joining the family business REM in 1981, he leads product development and is an expert in the optical industry's supply chain.

Mike Hundert is chief executive officer and chief creative officer of REM Eyewear. A journalist by education, a sports broadcaster and director of world pro skiing before joining the family business REM in 1981, he leads product development and is an expert in the optical industry's supply chain.

Nicolas Roseillier oversees product design and development of all REM Eyewear brands, as well as the company's luxury division, Base Curve.

Nicolas Roseillier oversees product design and development of all REM Eyewear brands, as well as the company's luxury division, Base Curve.

Credit Statement:

This course is approved for one (1) hour of CE credit by the American Board of Opticianry (ABO). Course SWJM263-2

Most people, sellers and consumers alike

assign a value to a product according to the

credentials of a designer's insignia, the

store in which it was bought or the stated

country of origin. In the world of eyewear

frames especially, that has often been the

case. However, to really evaluate a frame's

value, it's more than just its logo or "alleged"

country of origin.

Most people, sellers and consumers alike

assign a value to a product according to the

credentials of a designer's insignia, the

store in which it was bought or the stated

country of origin. In the world of eyewear

frames especially, that has often been the

case. However, to really evaluate a frame's

value, it's more than just its logo or "alleged"

country of origin.

UNDERSTANDING FRAME VALUE

Value is a combination of: brand, design, product components, material quality, manufacturing and the vendor from which the frame is purchased.

Brands: Brands affect perceptions and attitudes, creating the ability to charge a "brand premium." That is matched with the need for higher prices to offset both royalty payments and marketing commitments.

A brand guardian's (i.e., eyewear licensee)

job is to deliver on its promises, which

includes creating a lifestyle perception

embodied in its products that a consumer

can choose to experience. Eyewear may be

the easiest way that a consumer can have

access to an aspirational brand, usually out

of reach financially. For example, you can

spend $4,000 to drape a Chanel handbag

over your arm, or a tenth of that ($400 or

less) for a pair of Chanel sunglasses that

declare, "You're a Chanel woman."

A brand guardian's (i.e., eyewear licensee)

job is to deliver on its promises, which

includes creating a lifestyle perception

embodied in its products that a consumer

can choose to experience. Eyewear may be

the easiest way that a consumer can have

access to an aspirational brand, usually out

of reach financially. For example, you can

spend $4,000 to drape a Chanel handbag

over your arm, or a tenth of that ($400 or

less) for a pair of Chanel sunglasses that

declare, "You're a Chanel woman."

Every brand has a set of core values. It's in its DNA. Review the brands highlighted, and discover for yourself what comes to mind to sense the emotions a brand can emote. Build a brand book for your office.

List the three to five most important characteristics of every brand in your office. Visit every brand's Web page or grill your representatives to help build your brand book.

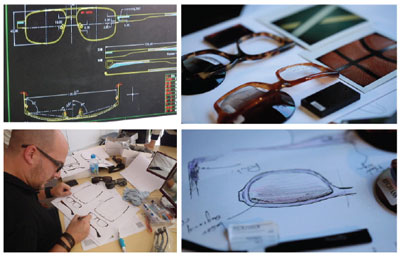

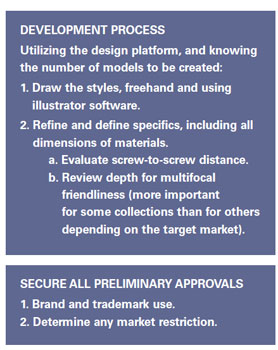

Design: The design process is a collaboration between designers and factory engineers to ultimately create the CAD drawings that lead to manufacturing. The designer is an artist that draws inspiration from culture and practicality. After all, eyewear is both a fashion accessory as well as a medical device. Combining cues from the fashion world with the wisdom of optical experience builds a high quality frame that will enhance a consumer's experience.

The designer must also be aware and manage the costs associated with the design. Each brand has a competitive matrix that must be respected from the price perspective.

The designer begins by establishing the foundation based on the brand's following and its consumer demographics, including age, income and lifestyle considerations.

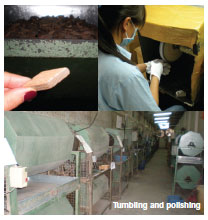

Technically, both design and engineering examine shape and form. They look for details such as the sharpness of angles that may make an acetate frame provocative on paper but difficult to achieve since standard "tumbling" that is used to give frames their luster rounds off edges and may destroy the designer's intent. The more successful models that fit a wider variety of faces are balanced, i.e., neither too "wingy" nor too "sad." Does the style and design reflect the brand's appropriate quotient of imagination, inventiveness, excitement, sophistication, fashion and uniqueness, faithful to the brand's core principle?

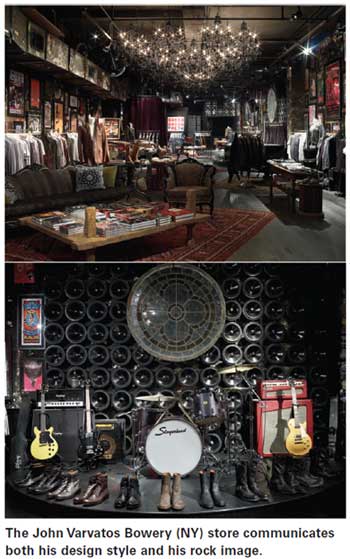

A designer usually creates some characteristics, often components, that are used consistently from model to model, weaving a cohesive story that brings a common identity to each style in a collection. Take the temple example from the John Varvatos Collection.

Each of its temples are capped-off with a metal piece that carries the brand's iconic symbols.

When building a sunglass collection, lenses and coatings are identified to be used throughout the brand's sun collection, creating an opportunity for additional storytelling that makes sense with the lifestyle of the consumers who best identify with that brand.

The difference between a brand and a product is that a brand has many "brand extensions," often in the form of licensed products, such as accessories... and eyewear. Designers of these various products share inspiration in an effort to ensure products under a brand are seamless in their attributes and consistent in delivering similar experiences.

Using those keys to trigger the imagination, the designer combines intuition and experience to develop a fashion-leading product. Most often, those ideas are then matched with the commercial realities that might temper the design. Or the objectives for one model might call for a style that screams out to garner attention for the collection at the expense of sales.

THE COLLECTION PLAN

At REM, we call it "The Perfect World." Those responsible for design, brand management, sales and inventory management agree precisely on how many models should be in a collection "in the perfect world." This is a living document, revisited and re-evaluated regularly throughout the year. We maintain such a plan for two years in advance given that product ideas often take 18 months or longer to bring to market. The Perfect World includes an outlook of how many new models will need to be phased out and introduced each year. For instance, today we would consider a trendier brand having more acetate (perhaps 50 percent) than is average (about 20 to 25 percent). The trendier the collection, the quicker the rotation. Women's collections generally turn over more frequently. Men are usually more conservative in their choice, making it unnecessary to create as many new styles each year. A decision on how much color and what colors are appropriate is decided upon, often including the brand's licensing managers in that discussion.

Creating a Perfect World in a dispensary is sound advice. A frame buyer (optician, manager, doctor) has the responsibility to know their clientele, including the local demographics. A buyer can create a product perfect world plan that matches that insight. If there are schools nearby be sure to have the appropriate choices for that age group. And remember: Don't judge a frame on how it looks on you! You may be far from the intended market for that frame.

MANUFACTURING

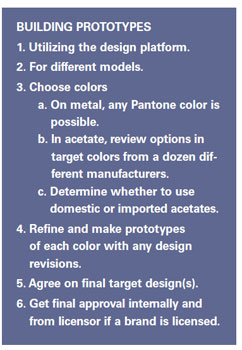

Production is the serious culmination of the design process. Manufacturing is complex, and the steps taken to make a resulting beautiful frame can often be taken for granted. It is not unusual for as many as 250 technical operations to take place to make high-quality frames. The result is a combination of high technology and creativity—the blending of science and art, just as frames are both a fashion accessory and a medical device. Read through these steps, look at the photos and imagine a tour of the factory.

|

|

|

PRODUCTION

1. Organize production lines. Develop the

tools and jigs as well as any molds and dies

necessary for production.

1. Organize production lines. Develop the

tools and jigs as well as any molds and dies

necessary for production.

2. Identify machinery needs. They may be any variety of CNC, laser, injection molding machines, etc.

3. Metal frame production begins with cutting the rim wires. This requires extreme precision, which often differentiates one factory from another. The quality of a factory can often be judged by their eyewire cutting processes. Remember, production from one order must be identical on all subsequent orders. This ensures that the ECP and their lab's experience is consistent from order to order.

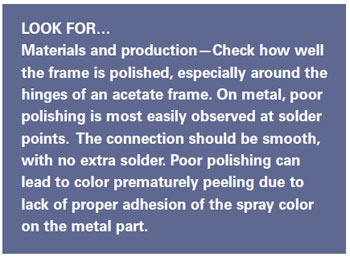

Eyewires are soldered to endpieces and the bridge, while temples are being machined and hinges are being attached. The metal frames are tumbled and hand polished for a smooth finish before going to plating and/or being subjected to other coloring techniques. The quality of coloring is affected by the quality of the frame's surface. A base is applied by electroplating, usually in gold, silver or a shade of gunmetal. The frame may then be coated with a color spray paint. The best quality paints for eyewear come from Switzerland.

Titanium frames are more expensive for several reasons. The raw material is more expensive, but the larger cost difference is due to its fabrication requirements. Titanium is extremely hard, requiring huge presses to stamp any impression into the material. Special welding equipment is used for titanium, as opposed to soldering equipment used for other metals. Coloring titanium is not always simple either since colors adhere differently to this material requiring special techniques.

Beta titanium is a springy alloy cousin to pure titanium (think Silhouette's three-piece mounting). This material is unique to work with as well. In this case it is neither soldered nor welded. If it does have a hinge (unlike Silhouette) the barrels of the hinge is stamped into the temple as it is being formed into a single piece.

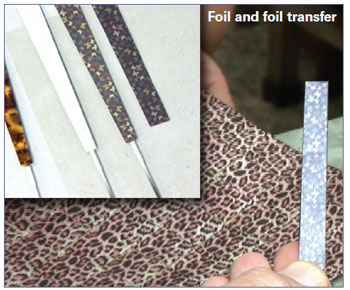

"Foil transfer" coloring is more complicated and is usually confined to metal frames. A design is created on a computer, which is then printed on a foil. The plated frame receives a clear lacquer coating. The foil is wrapped over the area where the color pattern is desired. It is then baked in an oven where the ink on the foil essentially melts from the foil into the lacquer coating. Once cooled, the foil is peeled off and the color appears on the frame. CNC and/or laser cutting is often used to reveal various layers of a laminated material. It is possible to "dial in" the depth of the laser cuts desired to control what layer is revealed.

4. Plastic handmade frames (not injection molded) can vary greatly by design. Materials are cut into rectangular pieces about the height and width of the frame front. Modern factories have invested highly in the past decade to automate the milling steps. While traditionally each cut of plastic meant moving the frame from one machine to another, today's computer assisted "CNC" machines feature multiple cutting blades that are directed to make specific cuts and bevels, including the eyewire groove, before spitting it out and grabbing a new piece of material. Multiple layer acetate provides infinite opportunities to cut and reveal various layers and colors. Tumbling for days amidst polishing agents and materials brings out the material's shine, which is then finished by hand polishing. Too much polishing can wear through the frame, destroying it. Meanwhile, temples are shaped and then "shot" with a wire core. Temple ornaments or plaques are attached in a variety of ways, including imbedding them into the plastic.

5. Injection molded frames are made in yet another way. Materials for optical injected frames are usually propionate, TR-90 (or its derivative), carbon graphite or similar. In each case, the materials come in sacks of pellets. The machine melts the pellets and forces them into a mold of the model's shape. When removed and cooled the part is popped out of the mold and another one is made. Meanwhile that frame part is tumbled smooth. Coloring can be done in the mold. In other words, if you want a black frame you can use black pellets. Other colors are usually spray-painted with paints that can be absorbed by these materials. Patterns can be made on the materials by masking off sections, or even by simply holding a mask up to the plastic when spraying it with color. If you want tortoise, then color the whole frame in a light brown, followed by holding up a mask that has a series of holes and then spraying that mask with a dark brown. Pull the mask away and you have a tortoise-like look. Molds for injection molding can be very expensive so high volume is required for a company to usually invest in molded products.

Some designs call for pad printing or digital printing. Pad printing is simple, printing what is created on a metal plate, the same technique used for most temple and demo lens markings. Digital printing is a relatively new art for eyewear. It is used most often to print any design on a plastic temple. The part is inserted into a special printer that applies the graphic to the plastic.

6. Acetate temples most commonly have their wire core "shot" or ultrasonically embedded into the plastic temple. Sometimes the wire core is also laminated into the temple. There are many core options, which is determined during design. Temple tips may have an embedded logo, which requires precision cutting, laying in of a foil logo and covering with epoxy.

7. Nosepads are chosen to meet a variety of functional and design needs. Size and system is decided upon during the design phase and is made to order during production, including the dimensions and orientation of the pads.

Metal frames also require choosing the type of nosepad arms and pad shape/size.

Acetate frame design requires selecting the size and angle of the pad placement, which depends on the audience. For Asian and African-American fits (those people with a "flatter" bridge) part of the production may have different nosepads, fit lower and with increased depth, flaring wider and faster.

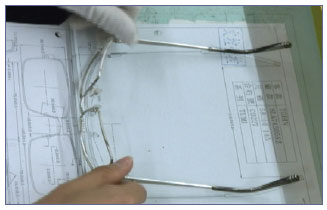

8. Finally the frame is assembled to bring all the component parts together. Frames are adjusted and compared to a CAD drawing to make sure the arc of the front and the bend of the temples are consistent and according to expectations of designs.

9. Cases and packaging are made in parallel at specialty case manufacturers.

10. Nonprescription sunglasses require a decision about bezel design. That determines whether the frame will also be Rxable. A "U-shaped" groove is commonly used for nonprescription sunglasses. A "V-shaped" groove is the common shape for products that will be Rxed. Sun lens material, colors, coatings and if polarized are determined in the design phase. They are sourced from lens manufacturers, and usually edged and glazed at an assembler. Where the sunglass lens work is completed often is the country of origin marking that appears on the frame. As an example, the frame can be made in China and shipped to a lens company in Italy. There, the lens company makes and glazes the lenses into the frame. Expect that frame marking to read "Made in Italy." This is yet another example why you need to know how to evaluate product well beyond the country of origin marking.

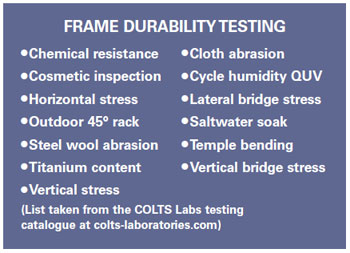

QUALITY ASSURANCE AND CONTROL

The frame has been manufactured but the quality of the intent must be confirmed. Quality assurance means that quality happens at all stages, not just at the end of production (quality control). Material quality is checked when received from component manufacturers (for example, hinge size and finish, nose-pad color and consistency), then at every stage of production and finally before packaging.

After a visual inspection, the frame is adjusted to the specs for front curve and tilt (pantoscopic angle).

Batch testing is used to ensure that all the design and operational features are delivered as specified.

The functioning of hinges can be tested using a mechanical device that opens and closes the temple hundreds of times to ensure that the hinge will not wear excessively or the screw design won't back itself out of the hole in the first week of wear. The finish is tested using a standard 3M-tape test. Like AR coatings, tape can be used to test adhesion with results predicting years of wearability under normal conditions. In fact, there are a variety of internationally agreed standards that frames meet and in some countries are required. For example, a common test for Europe's CE mark includes a sweat test to determine metal leaching as well as finish durability. Drop ball impact and optical tests for sunglasses and reading glasses are required.

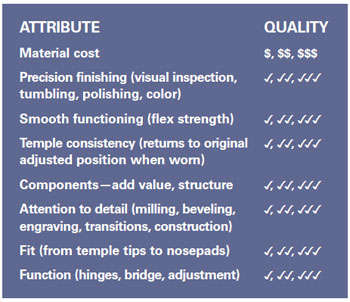

YOUR CHECKLIST: QUALITY VS. VALUE

Using the attribute table, review a product's attributes. Consider using the same checklist when showing customers the differences between that $100 and $400 frame. Mix and match the results for each of the categories.

In summary, know your materials. Understand that processes like casting, acid etching, coloring techniques, finishing steps and care, and the like all add to a frame's price. Brand names add to the cost through their required royalty payments and marketing requirements—not necessarily because the frame is any better or more expensive to manufacture. And please don't decide whether to carry a frame based on how it looks on you. You are one of many target markets.

VENDOR AND VENDOR PROGRAMS

And finally, make sure the suppliers you choose have your best interests at heart. Make certain they support you with information, education, point-of-sale materials, a good warranty, and keen knowledge of the industry and products they sell. What is their longevity record? Where are they when you need them? What is their fill rate? Nevertheless, timely resupply is the responsibility of your vendor. Ask about a company's "fill rate." The most reliable companies will have a fill rate (orders received today are shipped today) of about 95 percent. This company prides itself in a fill rate above 97 percent.

Look for frame suppliers whose knowledge, commitment and passion for the supply chain are superior, who can talk-the-talk of how their products are made that can help you educate consumers in ways that elevate your credibility and their comfort in following your advice.

PUTTING IT ALL TOGETHER

With the material presented in this course, you can now rely on a new knowledge, which is more accurate than evaluating a product based on its country of origin marking. Clearly, the country in which a product is made no longer assures its quality or value. More pertinent is the "factory of origin," since each is individually owned by people who have different commitments to excellence. Since you can't evaluate those factories, we hope this primer will assist you in defining product value that can lead to the ultimate objective—creating customer delight.